Retsch DM 200 User Manual

Page 14

16.11.2006

Retsch GmbH

14

Doc.Nr. GB 98.740.9999

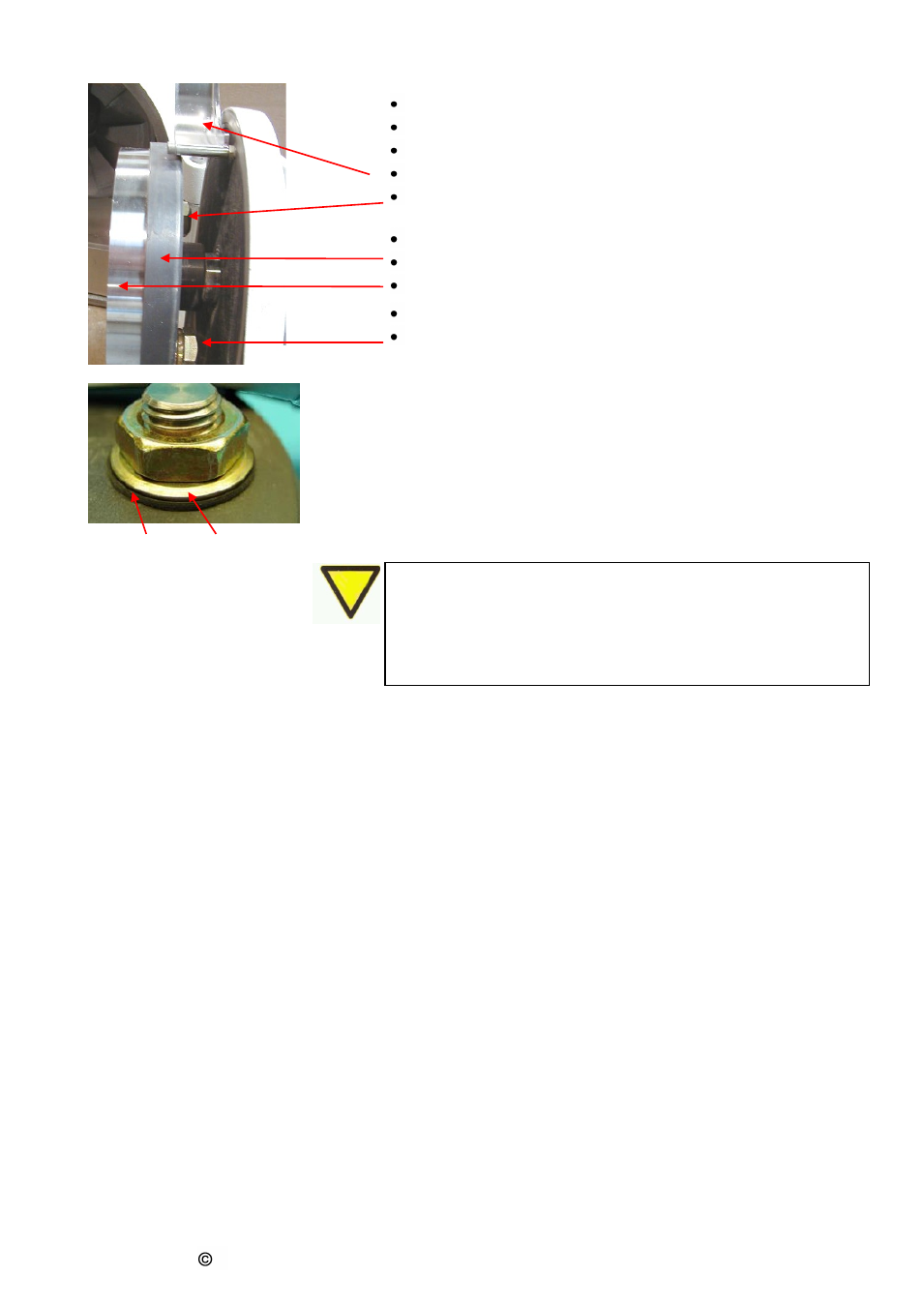

Replacing the milling disk in the housing:

Disconnect the mains plug

Remove the collecting vessel

Open the door

Lift up the cover

Unscrew the hexagon bolts or hexagon nuts with an SW

30 open-jawed spanner

Remove the milling disk

Clean the mounting of the milling disk

Place a new milling disk in position

The milling disk must have a level contact surface

Screw in the hexagon bolts with washers – for zirconium

oxide hexagon nuts are used.

GS

SS

Caution

It is essential that the milling disks have a level contact

surface.

There should be no unevenness or other components under

the milling disk.

For zirconium oxide disks it is absolutely necessary that the

rubber washer GS is placed under the steel washer SS.

Caution

Milling disks of zirconium oxide should be tightened with a

torque of only 20-30 Nm. Do not forget the rubber washer

GS.

Milling disks of steel and tungsten carbide are tightened

with a torque of 50-100 Nm.