Retsch DM 200 User Manual

Page 13

16.11.2006

Retsch GmbH

13

Doc.Nr. GB 98.740.9999

Changing the direction of rotation, re-

placing the milling disks

The milling disks are subject to natural wear after use over

a long period.

However, before they need to be replaced by new ones the

direction of rotation of the motor can be changed so that

the opposite side of the gear teeth can be used. By this

means the service life of the milling disks can be extended.

Changing the direction of rotation:

By reversing the phases of the mains supply the direction of

rotation of the motor can be changed. Since this necessi-

tates intervention in the electrical connecting line of the

DM200 the change in direction of rotation should be carried

out only by a qualified electrician.

However, it is possible to install a direction of rotation

change-over switch when connecting up to the mains supply

for the first time. It is then no longer necessary for an elec-

trician to intervene when the the direction of rotation has to

be changed again.

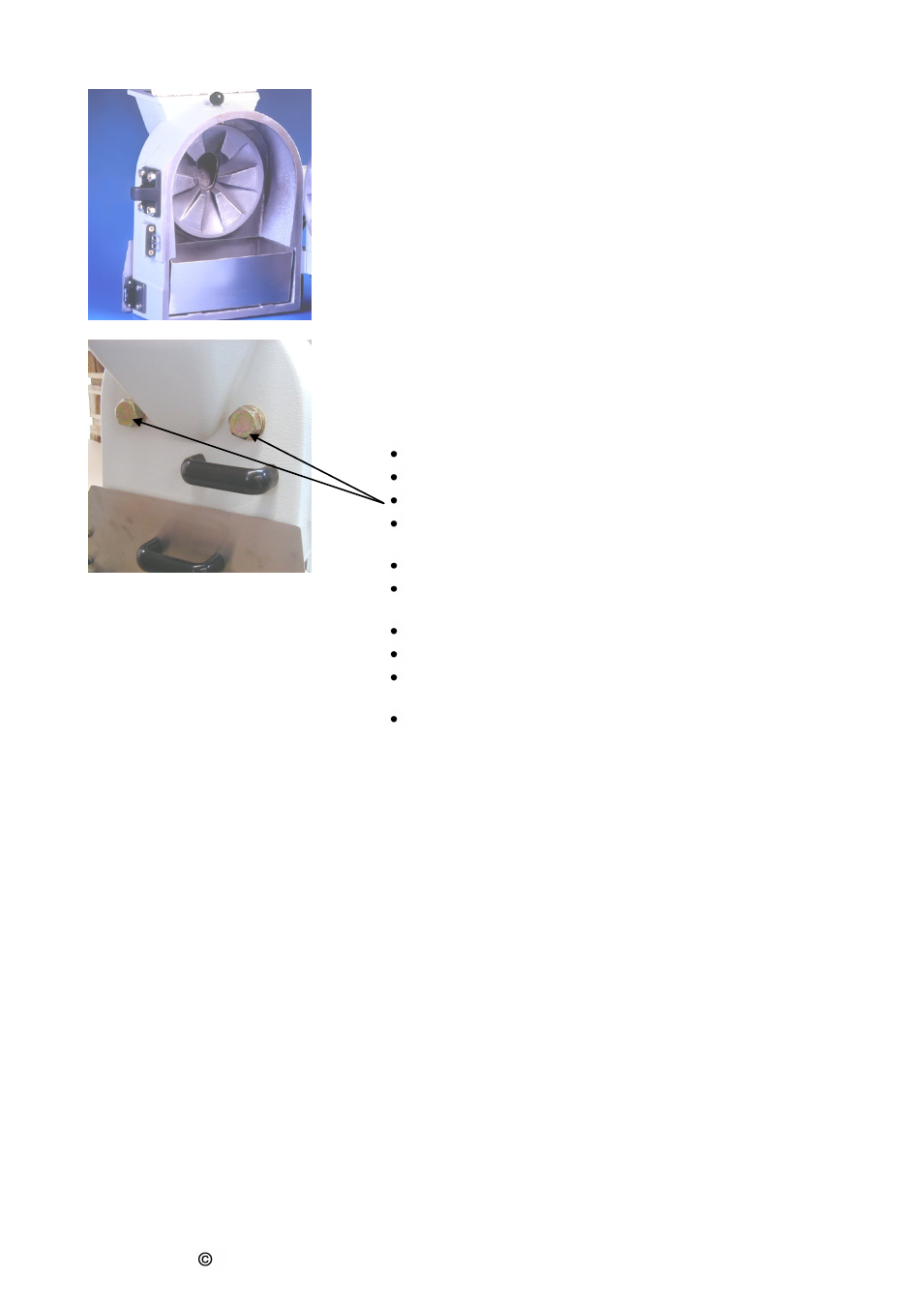

Replacing the milling disk in the door:

Disconnect the mains plug

Remove the collecting vessel

Keep the door closed

Slightly unscrew the hexagon bolts or hexagon nuts with

an open-jawed spanner

Open the door

Keep a firm hold on the milling disk while unscrewing

both hexagon bolts with washers

Remove the milling disk

Clean the mounting of the milling disk in the door

Insert a new milling disk so that its contact surface is

level

Screw in the hexagon bolts again – for zirconium oxide

hexagon nuts are used