Retsch DM 200 User Manual

Page 12

16.11.2006

Retsch GmbH

12

Doc.Nr. GB 98.740.9999

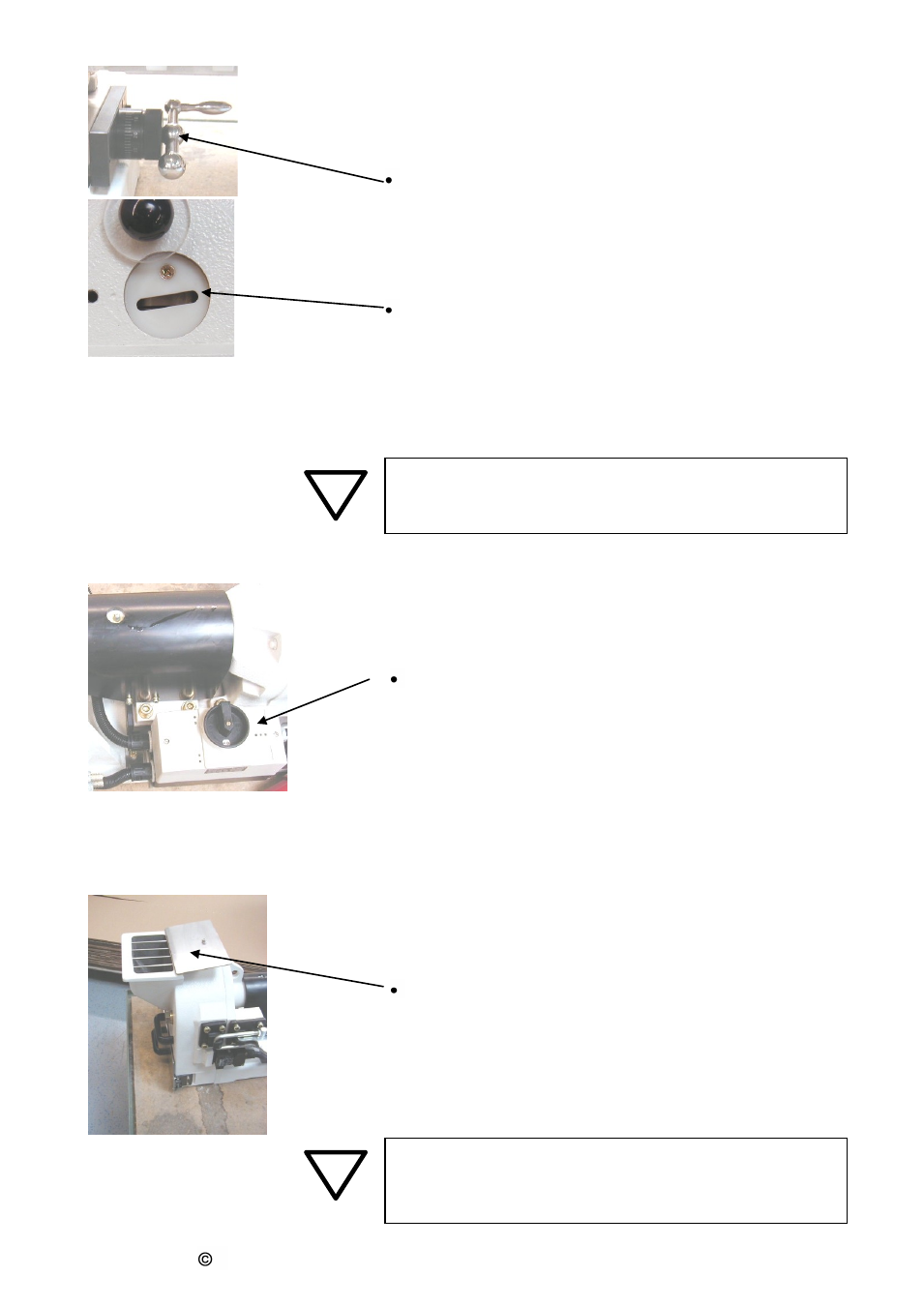

Adjusting the Gap Width

You may adjust the gap width between the milling disc in

the housing and in the door just by adjusting the gradu-

ated rotating crank mounted below the motor. 1 gradua-

tion line = 0.01 mm.

You may adjust the gap from 0.1 to approximately 5 mm.

Rotating Crank

Caution! Do not go below the minimum gap width of 0.1

mm.

You may control check the gap width setting through a

window behind the funnel tube by means of a sensing

gauge.

Window

You may also adjust the gap width when the machine is

running.

Material that is difficult to mill should be milled at least

twice. Select a larger gap width as pre-crushing for the

first pass and then you achieve the desired final fineness

with the small gap in the second milling pass.

Caution !

The smallest gap width is 0.1 mm.

The milling discs may not touch one another because otherwise

this could damage the milling discs.

Starting the Machine

It is only possible to start the DM200 when the door is

closed and the collecting container has been inserted.

The ON-OFF switch is on the right-hand side of the

DM200.

ON-OFF switch

position [I] DM200 starts

position [0] DM200 stops

The ON-OFF switch also acts as a protective motor

switch.

If the motor is overloaded or if there is another electrical

fault, this switch disconnects the DM200 from the mains.

The DM200 can only start up when the DM200 is

manually started with the ON-OFF switch.

Feeding the Material to be Crushed

After the gap has been set and the DM200 has been

started, you commence material feed. Do not exceed a

maximum edge length 20 mm. Open the lid of the funnel

tube for this purpose.

the lid of the funnel tube

When feeding the material to be crushed, please ensure

that the funnel tube lid is closed because otherwise the

material to be crushed could fall back.

Furthermore, the quantity of fed material to be crushed

depends upon its millability. Therefore, note the decreas-

ing intensity of the milling sound to ascertain the opti-

mum feed quantity.

Caution!

Only feed the material to be crushed after having started the

DM200.

If the DM200 starts up filled with material to be crushed, this

may lead to damage in the mechanical component parts.