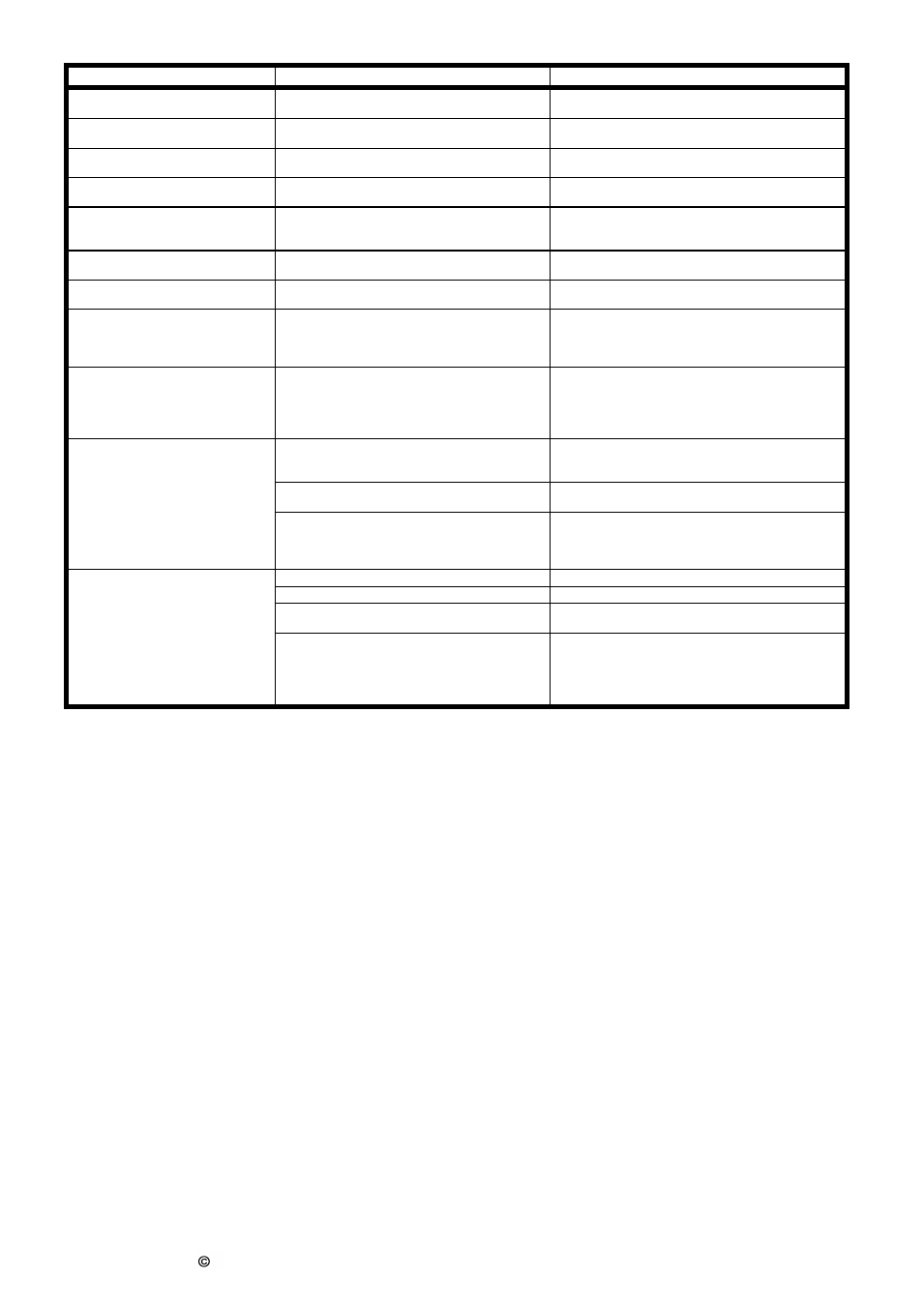

Safety instructions (table) – Retsch BB 300 User Manual

Page 19

07/02/2012

Retsch GmbH

19

Safety instructions (table)

for the BB 300 taken from the chapters

Procedure

Action

Dangers

Safety

Not paying attention to the safety instructions can

lead to damage to people and property.

Claims for damage are excluded in whatever form.

Packaging

Please retain the packaging for the duration of the

guarantee period.

In the case of complaint your warrantee rights can be

endangered if the item is returned insufficiently packaged

Transport

During transportation the BB 300 should not be

knocked, shaken or thrown.

Electronic and mechanical components can become

damaged.

Temperature variations

With severe variations in temperature, the BB 300

must be protected from condensation.

Electronic components can become damaged.

Scope of delivery

In the case of the delivery being incomplete and/or

transport damage, you must inform the carrier and

Retsch GmbH immediately (within 24 h).

Later complaints can under certain circumstances no

longer be considered.

Environmental temperature

Drops below 5°C

Rises above 40°C

Electronic and mechanical components can become

damaged. Performance data change by an unknown extent.

Air humidity

Rises above 80%

at temperatures up to 31%

Electronic and mechanical components can become

damaged. Performance data change by an unknown extent.

Mounting the hopper

In order to be sure to be able to guarantee the

transport, the BB 300 has been delivered with a

dismounted filling hopper. It is not permissible to run

the BB 300 without a filling hopper mounted.

Danger of crushing for fingers and hands.

Electrical connection

Mains supply does not match the values given on the

type plate.

Before initial operation, the direction of rotation is to

be checked, see rotation direction arrow on the motor.

Electronic components can become damaged.

If the direction of rotation is wrong, no satisfactory milling

will take place and mechanical components can become

damaged.

Operation

During starting, stopping and disconnection, there

must be no material for grinding in the crushing

chamber or in the feed hopper.

Mechanical components can possibly become damaged via

a blockage.

Do not set gap width below 1 mm.

Mechanical components can possibly become damaged via

a blockage.

The crushing chamber is not be filled by more than

2/3.

Otherwise the guide plates of the feed hopper can

becoming damaged and the material for grinding will be

delivered by the breaking arm into the crusher housing

behind the arm.

Cleaning

Each time before cleaning, pull out the mains plug.

Danger of death by electrocution.

Do not clean with running water.

Danger of death by electrocution.

Solvents are not permitted.

Since they would damage the felt seals on the sides of the

breaking arms or wash out the grease filling.

The filling hopper may be swung back for cleaning, by

unscrewing the two socket screws, only by assigned,

trained personnel. Operation of the BB 300 without

screwed-in socket screws and without the filling

hopper is not permitted.

Danger of crushing for fingers and hands.