Feeding in process material – Retsch BB 300 User Manual

Page 15

07/02/2012

Retsch GmbH

15

Do not set the gap width of the BB 300 to below 1 mm.

Mechanical components can be damaged if there is blockage.

Feeding in process material

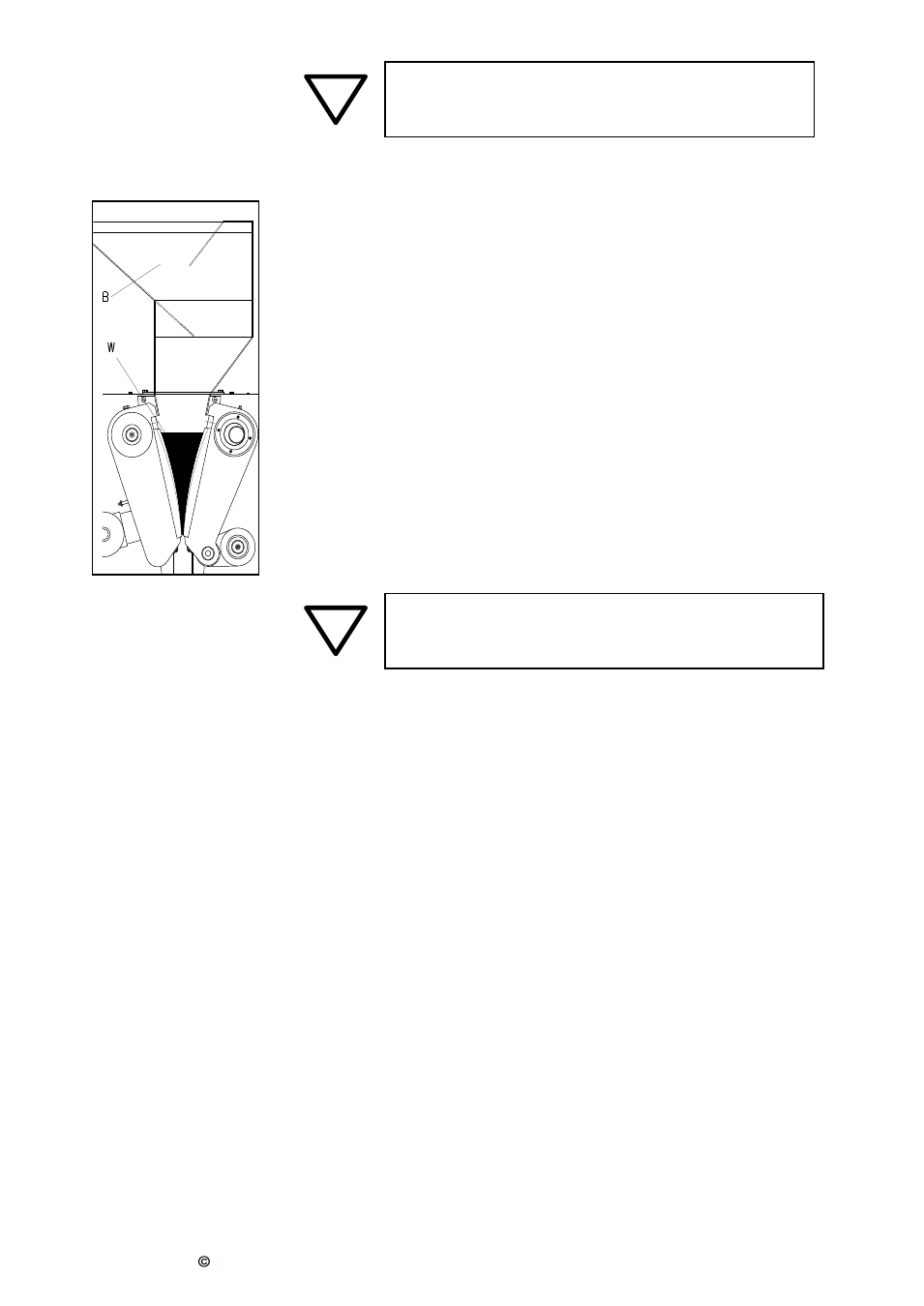

Fig.6

The feed hopper B can accept process material with grain sizes up to

130 mm. Only fill the feed hopper and the crusher chamber when the

machine is running.

The feed hopper is not however intended for storage of process

material: its function is solely that of feeding material into the crusher

chamber. It also prevents inadvertent reaching into the crusher

chamber, and stops process material from being ejected.

Fig.6

If the crusher chamber W is filled more than 2/3 (3500ml), the guide

plates on the feed hopper can be damaged and process material

conveyed by the moving crusher arm into the crusher casing behind

the crusher arm.

- BB 50 (41 pages)

- BB 100 (24 pages)

- BB 200 (24 pages)

- Cryomill (68 pages)

- CryoMill Autofill 50l (28 pages)

- DM 200 (20 pages)

- DM 400 (60 pages)

- Emax (67 pages)

- GM 200 (44 pages)

- GM 300 (44 pages)

- MM 200 (32 pages)

- MM 400 (32 pages)

- PM 100 (44 pages)

- PM 400 (36 pages)

- PM GrindControl (48 pages)

- RM 200 (36 pages)

- RS 200 (32 pages)

- SK 100 (24 pages)

- SM 100 (48 pages)

- SM 200 (48 pages)

- SM 300 (44 pages)

- Cyclone - SM 300 (20 pages)

- SR 200 (24 pages)

- SR 300 (24 pages)

- TWISTER (44 pages)

- ZM 200 (32 pages)

- AS 200 jet - Automatic Vacuum Regulation (6 pages)

- AS 200 control - natural frequency (32 pages)

- AS 200 (36 pages)

- AS 200 jet (56 pages)

- AS 200 jet (48 pages)

- AS 200 tap 30.025.0001 (28 pages)

- AS 200 tap 30.025.1001 (28 pages)

- AS 300 (32 pages)

- AS 400 (32 pages)

- AS 400 (28 pages)

- AS 450 basic (40 pages)

- AS 450 basic (44 pages)

- AS 450 control (52 pages)

- DR 100 (40 pages)

- DR 100 (28 pages)

- PP 25 (32 pages)

- PP 40 (28 pages)

- PT 100 (36 pages)