General – Retsch BB 300 User Manual

Page 17

07/02/2012

Retsch GmbH

17

General

Cleaning

Cleaning of the BB 300 is best effected with an industrial vacuum

cleaner and a robust, long-handled brush.

!

The feed hopper may only be dismantled by trained specialists, by

removing the eight hexagon screws, for cleaning purposes. Operation

of the BB 300 with the feed hopper removed is impermissible.

Risk of crushing fingers and hands!

!

Do not clean the BB 300 with running water.

Lethal hazard of electric shock

Solvents must not be used, as the felt seals on the sides of the crusher

arms would be destroyed, and grease packing washed out.

Maintenance

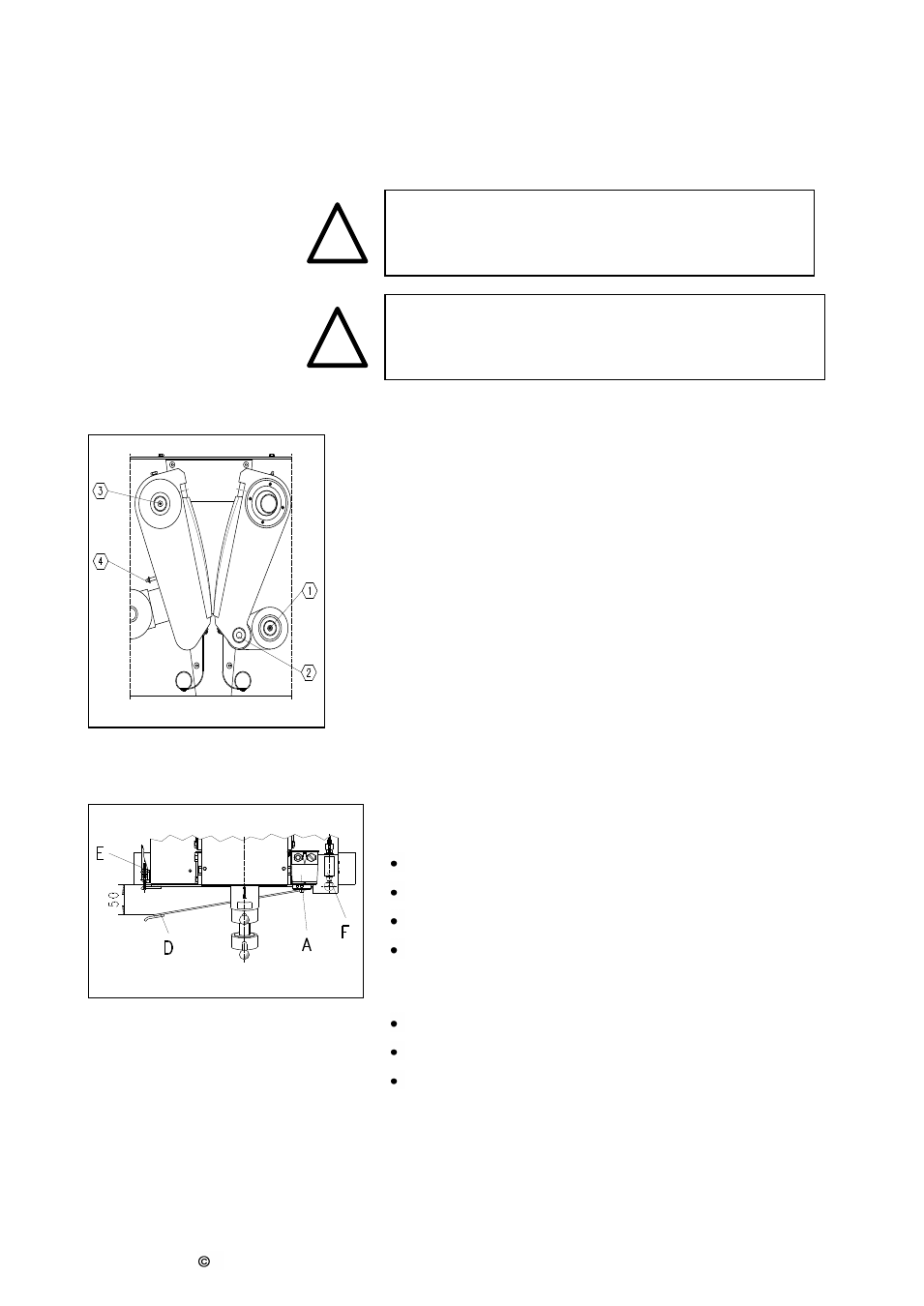

Fig.8

The BB 300 requires relubrication from time to time. Fig.8

Please consult the table below for quantities of lubricant and intervals.

The positions of the lubrication points are marked by red arrows on

the machine.

No.

Quantity in kg

Interval in operating hours

1

0.025

50

2

0.005

50

3

0.003

500

4

0.005

500

Points not shown in Fig.8 but marked with arrows are permanently

lubricated.

Please use the grease gun supplied with the BB 300 for lubrication.

As the lubricant, a conventional multipurpose grease can be used, e.g.

EP 4685 from ESSO/SHELL or BP.

Tests

Fig.9

The function of the limit switch on the door is to be tested every six

months. Fig.9

Start the BB 300.

Open catch E.

Open door D until the gap on the left is 50 mm.

Limit switch E must operate, and the BB 300 stop.

If the limit switch does not operate, it requires resetting as described

below, or otherwise

Close door D and catch E.

The BB 300 must not start.

Start the BB 300 at main switch A.