Retsch BB 200 User Manual

Page 14

04/05/2012

Retsch GmbH

14

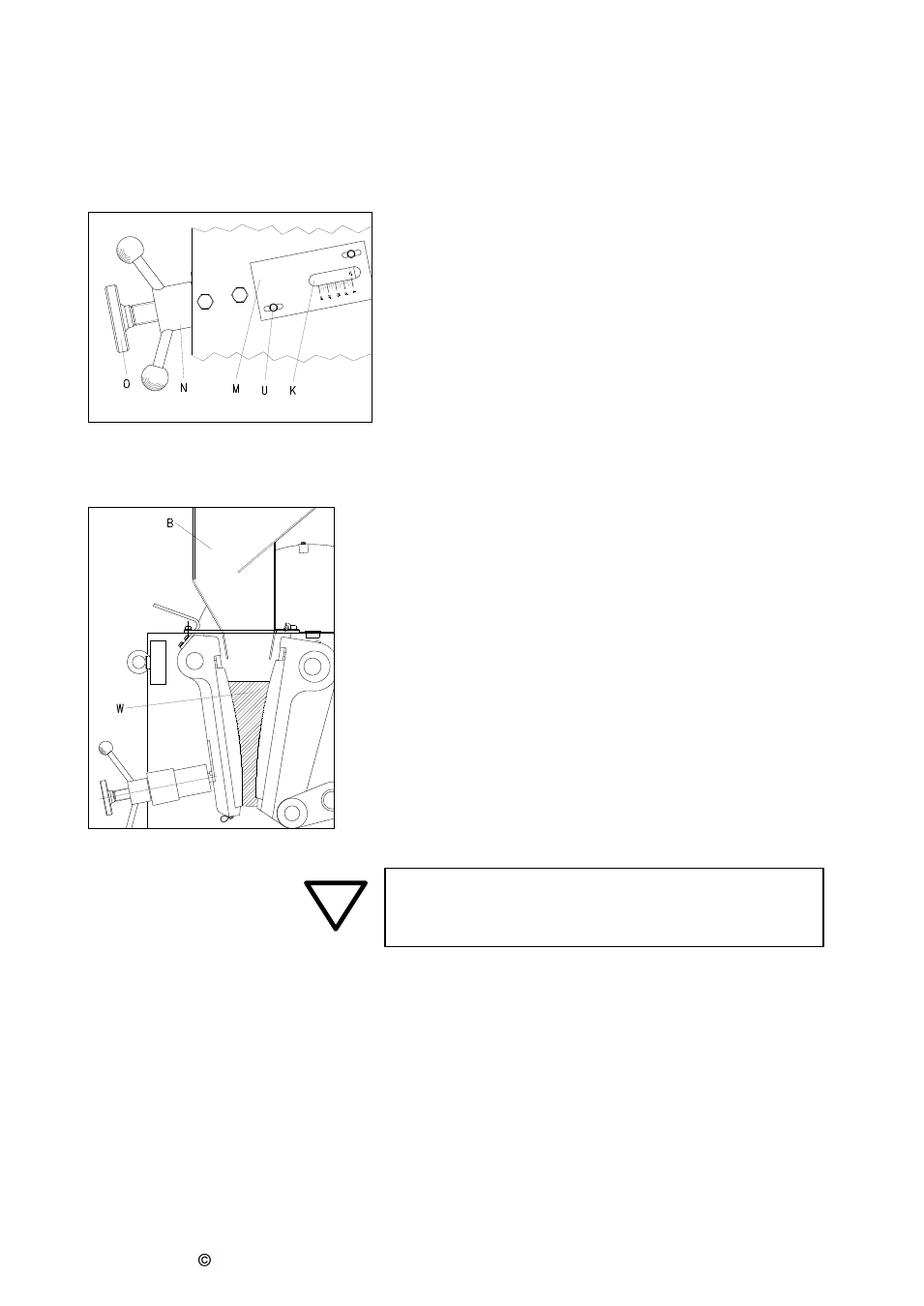

Adjust the gap width

Fig. 4

* Start the BB 200 (idling, without product).

* Loosen the lock nut N (turn to the left).

* Turn the spindle O to the right to reduce the gap.

* Turn the spindle O to the left to enlarge the gap.

* The pointer K shows the approximate gap width at the scale

M.

* Re-tighten the lock nut N (turn to the right).

Fig. 4

Adjusting the zero setting for the gap width

* Start the BB 200 (idling, without product).

* Loosen the lock nut N (turn to the left).

* Turn the spindle O to the right until you hear the two

breaker arms make contact.

* Loosen the machine screws U (turn to the right).

* Slide the 0 mark at the scale M to align with the tip of the

pointer K.

* Re-tighten the machine screws (turn to the right).

Fig. 4

Fill product to be ground

The fill hopper B can accept product up to grain sizes of 90

mm.

This hopper is not intended, however, to store a reserve of

product; its function is exclusively to feed material to the

grinding chamber and to keep ground product from being

ejected.

Fig. 5

Fig. 5

If the grinding chamber W is filled more than 2/3 full, then the

guide plates of the fill hopper could be damaged; the moving

breaker arm would force the product into the crusher housing,

behind the breaker arm.