Retsch BB 200 User Manual

Page 12

04/05/2012

Retsch GmbH

12

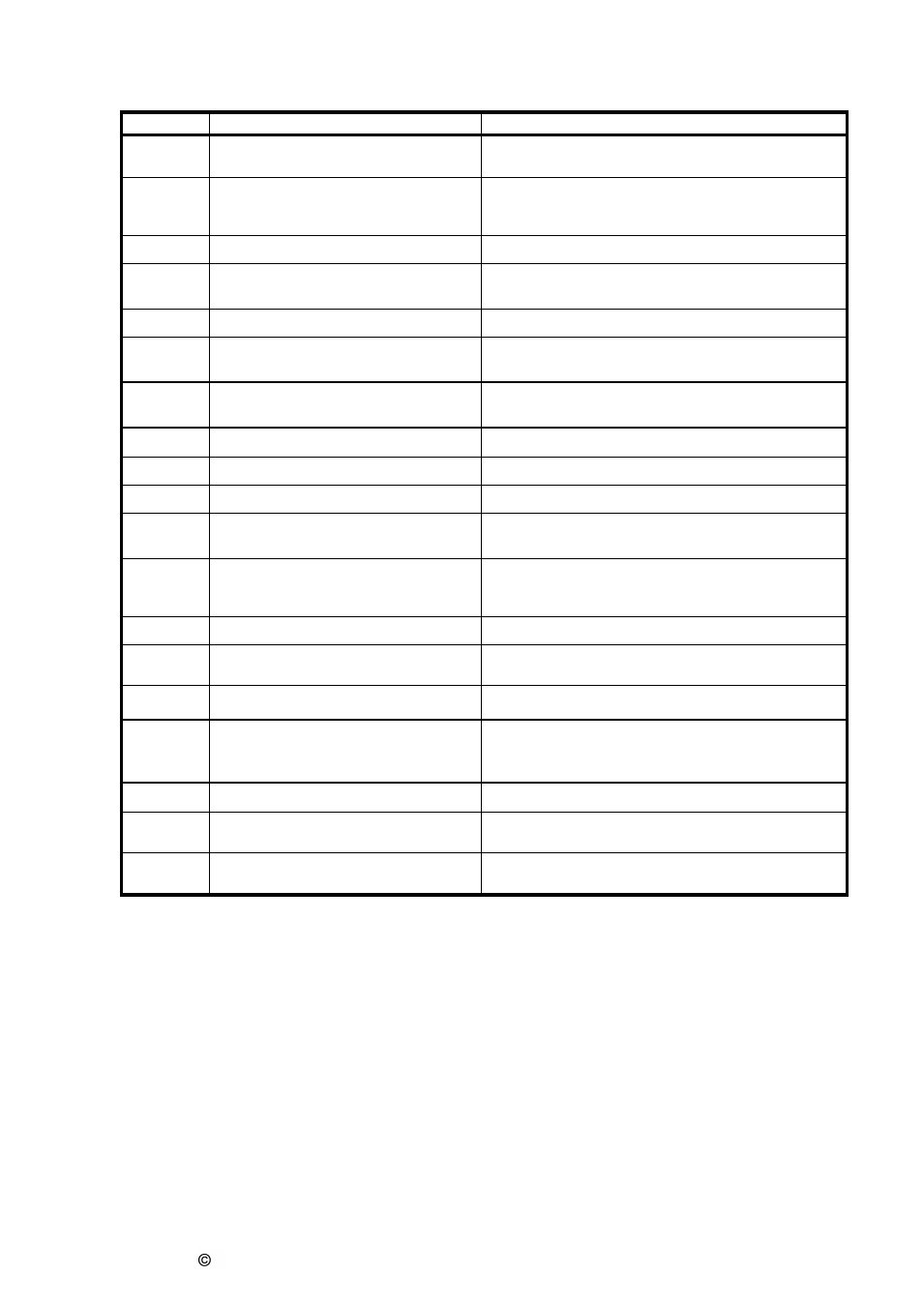

The operating controls and their functions

Summary table

Element

Description

Function

A

ON/OFF switch and motor protection

switch

Starts and stops the jaw crusher drive; isolates the motor

from the power supply in case of overloading

B

Fill hopper

Provides for the feed of material; prevents unintentionally

reaching into the grinding chamber; prevents ejection of

the material being processed

C

Receiver drawer V = 5 dm

3

Accepts the ground sample material

D

Hand barrier

Prevents unintentionally reaching into the grinding

chamber

E

Hex-head bolt

Affixes the hand barrier

F

Two machine screws

The fill hopper B can be swung to the rear once these

screws have been removed.

G

Limit switch

Disables the drive (motor) when the fill hopper B is not in

its normal operating position

H

Clamping shim

Secures the breaker jaws J

on the breaker arms

S and T.

I

Machine screw

Secure the clamping shim H

J

Breaker jaws

The size reduction components proper

K

Pointer

Indicates at scale M the width of the gap, at a tolerance of

±1mm

M

Scale

Indicates, in conjunction with the pointer K, the width of

the gap; used to zero the gap width adjustment to

accommodate for breaker jaw wear.

N

Lock nut

Locks the threaded spindle O

O

Threaded spindle

Increases the gap width when turned to the left, decreases

when turned to the right

P

Screw eyes

Lifting points when using lifting tackle to move the device

Q

Pin

When the pointer K is removed and the fill hopper B

swung to the rear, the pin can be pulled out and the

breaker arm S removed.

R

Wearing plate

Prevents damage to the side panels

S

Breaker arm, stationary

The breaker jaw J is mounted here; the gap width can be

modified by adjusting the threaded spindle O.

T

Breaker arm, moving

The breaker jaw J is mounted here; executes the grinding

motion required for size reduction without manual effort