MacDon FD75 Combine Header Quick Card User Manual

Page 2

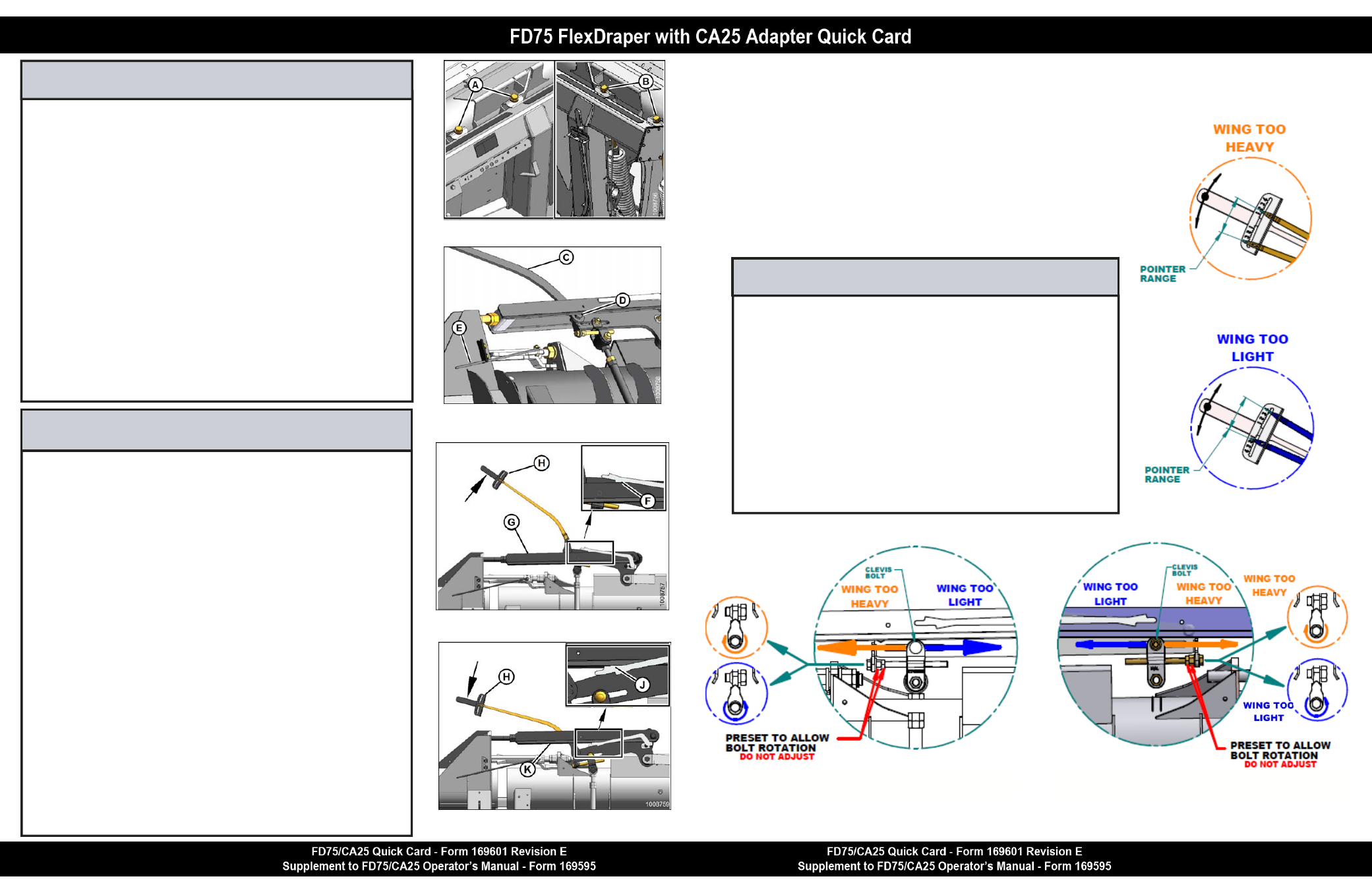

1. Use the readings taken in STEP 4, and the images on this

page to determine if the wing is too heavy or too light.

2. Loosen the clevis bolt for the wing requiring adjustment.

3. Balance the wing according to the Wing Balance Adjustment

Detail image below.

4. Tighten the clevis bolt.

5. Repeat

STEPS 4 and 5 for the opposite wing (if necessary).

6. Re-install poly linkage covers.

STEP 5: ADJUST WING BALANCE

Left Side Wing Balance Adjustment Detail

Right Side Wing Balance Adjustment Detail

1. Remove poly linkage covers.

2. Place torque wrench (C) on bolt (D).

3. Move spring handle (E) to lower position so that lock link drops

into lower slot.

NOTE

If lock link does not engage lower slot, move

with torque wrench (C) until lock link moves into

slot.

4. Move

wing

upward with torque wrench (C) until pointer lower

alignment tab (F) lines up with upper edge of top link (G). Note

indicator reading (H) on wrench.

5. Move

wing

downward with torque wrench (C) until pointer up-

per alignment tab (J) lines up with the lower edge of the top link

(K). Note indicator reading (H) on the wrench.

6. If

the

difference between the readings is 1 or less, the wing is

balanced and no further adjustment is required.

7. If

the

difference between the readings is more than 1, the

wing is not balanced. Record the readings and proceed to

STEP 5.

STEP 4: CHECK WING BALANCE

1. Refer to TABLE 1 for recommended initial float setting:

•

If reading on wrench is high, header is heavy, so increase

float.

•

If reading on wrench is low, header is light, so decrease float.

2. Adjust header float to match values in TABLE 1. Turn each bolt

pair equal amounts.

•

To increase float (lighter header), tighten (clockwise) float

spring bolts (A) and (B).

•

To decrease float (heavier header), loosen (counter clock-

wise) float spring bolts (A) and (B).

•

Ensure wrench reading is EQUAL ON BOTH SIDES

NOTE

For 40 and 45 ft. double-knife headers, adjust float

as above, and then loosen RIGHT SIDE FLOAT

spring bolts (B) 2 turns.

STEP 3: SET HEADER FLOAT

LEFT SIDE FLOAT RIGHT SIDE FLOAT

LEFT SIDE SHOWN, RIGHT SIDE OPPOSITE

WING UP

WING DOWN