MacDon A Series Quick Card User Manual

Page 2

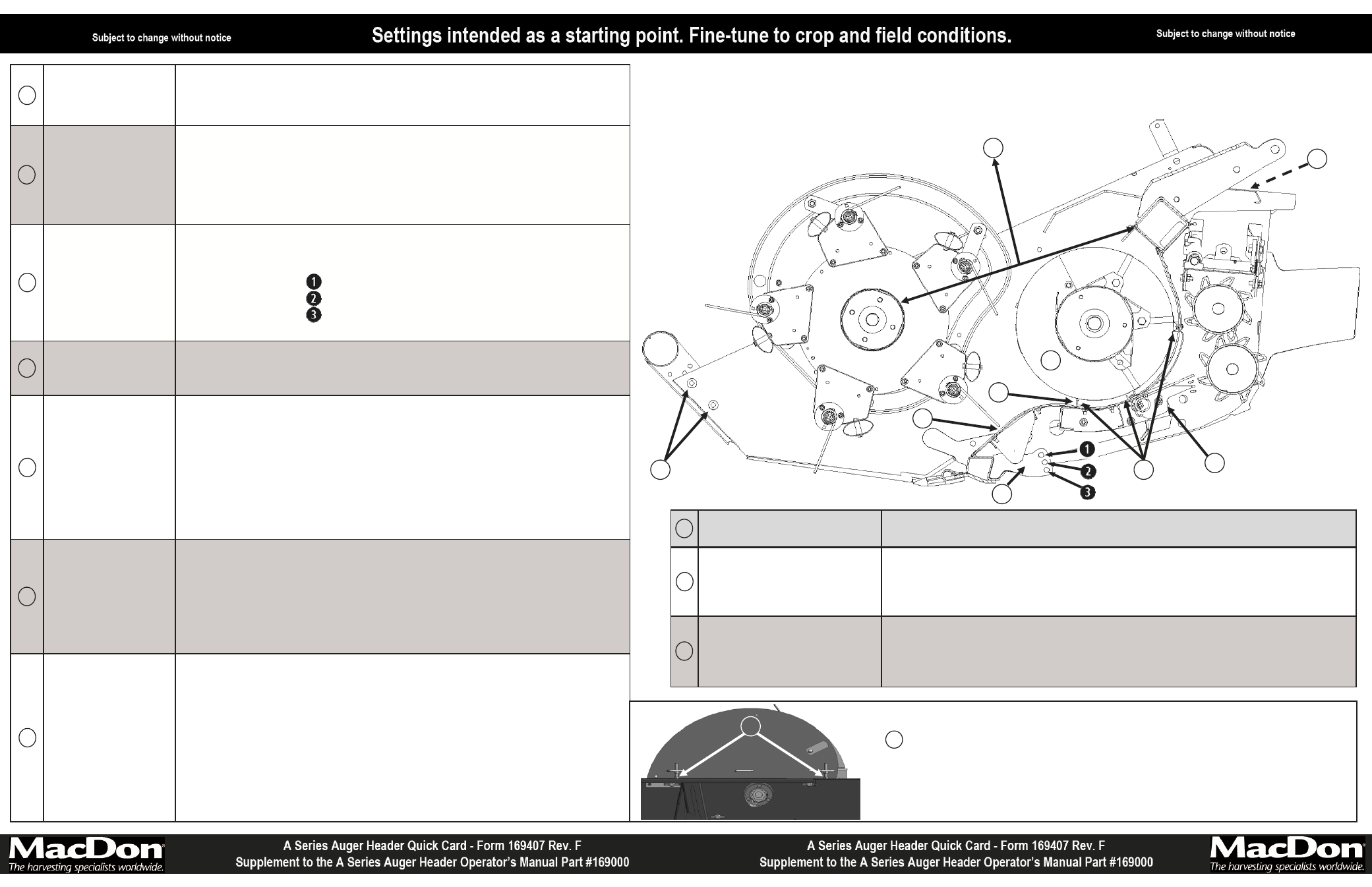

H

Feed Pan / Rock Drop Tine

Adjustment

Adjust pan up for light crops and down for tall, heavy crops.

J

Front Stripper Bar

Extensions

Depending on crop type and conditions, it may be necessary to add 8 in. (203 mm) long

front stripper extensions at the delivery opening.

Extensions can be added to reduce end feeding in tall crops.

Remove extensions if excessive center feeding occurs.

K

Auger Speed

Auger speed adjustment on A30 series is via sprocket. A40 series is hydraulic.

Adjusting auger speed can change your windrow shape.

Increasing auger speed will throw more crop to the middle of the windrow.

Decreasing auger speed will allow crop to fill the outside edges.

G

A

Lean Bar

Height should be set at 2/3 (two-thirds) of the crop height. This will bend the crop

forward exposing the stalks to the sickle.

In tall crops (more than 5 ft.[1.52 m]), consider installing the optional Tall Crop Divider

Kit (B4690) that includes lean bar extensions to raise the lean bar higher.

B

Reel Tine

Finger to Pan

Clearance

Setting the reel tine to pan gap ensures that reel tines are close enough to the cutter

bar/pan to move crop effectively off the cutter bar, and into the auger.

Reel tine fingers should be 0.08–0.39 in. (2–10 mm) away from the pan.

IMPORTANT: If there are a few reel tine fingers that are touching the pan while the

rest are at the correct height, trim the longer tines to match the rest. Be sure to

adjust both sides of the reel. Ensure that tines do NOT contact plastic header pan.

C

Skid Shoe Position

Adjusting the skid shoe position will change the cutter bar height.

1. Raise header, engage windrower cylinder stops, and pull the pin from skid shoe.

2. Adjust to the desired height, and re-insert pin.

Position - fully raised shoe = lowest cutting height

Position - mid-range setting

Position - fully lowered shoe = highest cutting height

NOTE: Gauge rollers are optional for A series headers.

D

Auger to Stripper

Bar Clearance

Setting the auger to stripper bar clearance will help move the crop more evenly from

the sides of the header into the conditioner.

There should be a gap of 1/32–5/32 in. (1–4mm).

E

Conditioner Roll Gap

Adjustment

(the amount of

conditioning action)

The roll gap determines how much the crop is conditioned.

1. To reduce conditioning: increase roll gap, loosen jam nut, and turn lower nut

clockwise.

2. To increase conditioning, decrease roll gap, turn lower nut counterclockwise.

3. Then, tighten the jam nut to secure the position.

Suggested initial settings:

Medium Alfalfa: 1/4–3/8in. (6–10 mm) / Large Stalk

Tall Crops (Sudan): 1 in. (25 mm) / Timothy

Wild Grass: 1/4 in. (6 mm)

F

Reel Position

Adjustment

Reel fore-aft position is factory set at 32.25 in. (819 mm) from the reel tube to the tube

on the rear of the frame (suitable for most crop conditions).

In severely down or lodged crops, the reel can be moved forward to increase crop

lifting action.

For optimum feeding in lighter crops, the distance between reel and auger must be as

close as possible. An alternative to moving the reel forward is to tilt the header for-

ward until the tines just brush the ground.

G

Reel Cam Pitch

Adjustment

Reel cam pitch can be adjusted to change the aggressiveness of the reel tines as

they enter the crop. Increasing tine aggressiveness also raises the release point in

front of the auger.

Reel is factory-set with 1/2 in. (12.5 mm) difference between the front and rear cam

adjuster bolts. NOTE: The front bolt is the lower of the two bolts.

To increase reel tine aggressiveness, lower the front bolt, and raise the rear bolt.

On RH side of the reel, adjustment bolts control reel pitch and height.

On LH side of the reel, adjustment bolts control the reel height only.

NOTE: Slacken reel cam and endsheet bolts before adjusting tighter after making

adjustments.

H

D

C

K

E

F

J

B

A

IMPORTANT - For windrowers with Reverser Kit B4656: To prevent draper header reel damage and improper operation:

If switching between A40 Auger Header and Draper Header, hose plumbing to reverser valve must be changed to suit the

header type. See Instruction MD Part #169213 for proper plumbing for each header type.

G Reel Cam Pitch Adjustment Bolts:

On the RH side of the reel, adjustment bolts control reel pitch and height.

On the LH side of the reel, adjustment bolts control the reel height only.