MacDon D65 Quick Card User Manual

Page 2

4

Reel Speed

Operate the reel at suggested percentage above ground speed.

Reel speed is displayed on the Cab Display Module in mph, km/h, or rpm,

and is adjustable with the controls in the windrower cab.

6

Float

The recommended float setting is 75–85 lbs. Rocky conditions, or cutting at

faster ground speeds, may require that float be set heavier to prevent exces-

sive header movement. See M-Series Operator’s Manual for procedures.

Draper Speed

Draper speed is to be set based on ground speed, crop mass, volume, and windrow formation. Faster ground speeds or heavier crop may require increased draper

speeds to convey material. Slower ground speed or lighter crop may require slower draper speeds to ensure even crop flow. See M Series Operator’s Manual.

5

Reel Fore-Aft

Use back edge of reel cam disc and

decal on reel support arm as a gauge.

Adjust fore-aft position with fore-aft

controls in windrower cab.

2

Knife Speed

Displayed as actual strokes

per minute on the windrower

Cab Display Module (CDM).

High – Upper part of range

Medium – Middle of range

Low – Lower part of range

Header Size

Recommended Knife

Speed Range (SPM)

Single Knife

Double Knife

15 ft.

---

1500–1900

20 and 25 ft.

1200–1400

1400–1700

30 ft.

1200–1400

1200–1600

35 ft.

1100–1300

1200–1400

40 ft.

1050–1200

1100–1400

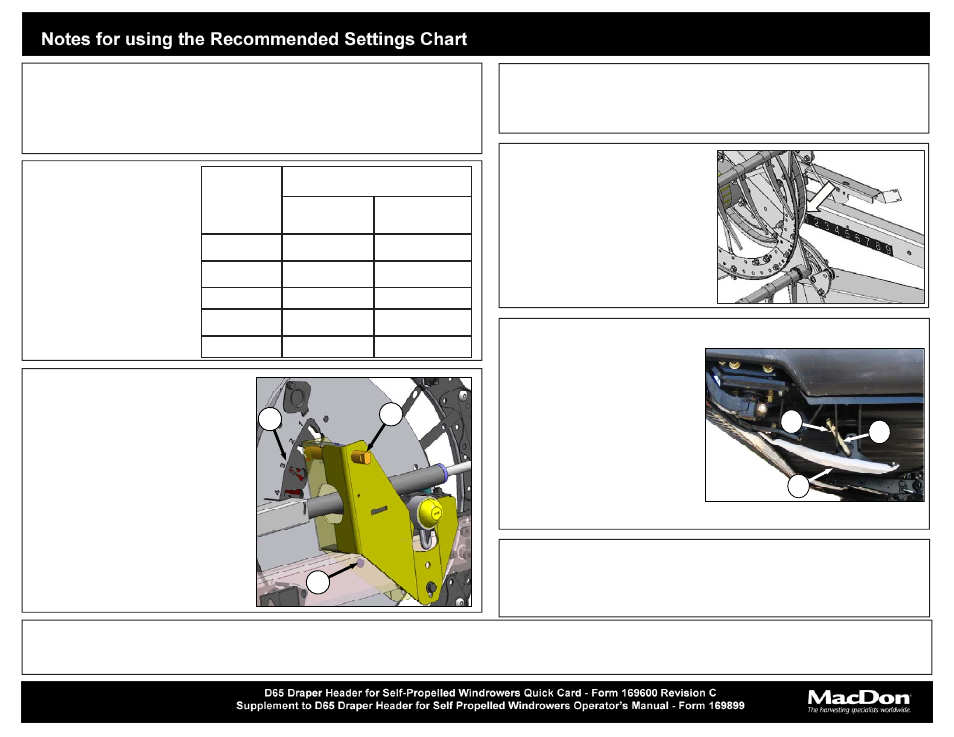

1

Header Angle

The header angle is varied by adjusting the length of the center link. It is used to

adjust the angle of the guards and draper deck relative to the ground.

The angle is displayed as a value from 0 (shallow) to 10 (steep) on the windrower

Cab Display Module (CDM).

3

Reel Tine Pitch

Turn cam latch pin (A) to unlock

cam disc.

Use wrench on bolt (B) until latch

pin lines up with appropriate

Cam setting (C) between 1 and 4.

Increasing the cam setting

increases the aggressiveness of the

reel for picking up downed crop.

C

A

B

6

Skid Shoes

Remove lynch pin (D), disengage

pin (E) from the frame, and move

skid shoe (F) to desired position.

There are three hole positions:

top, middle, and bottom.

For a lower cutting level, raise the

skid shoe by installing pin (E) in

the bottom hole.

For a higher cutting level, lower

the skid shoe by installing pin (E) in

the top hole.

F

E

D