MacDon M205 Quick Card User Manual

Page 2

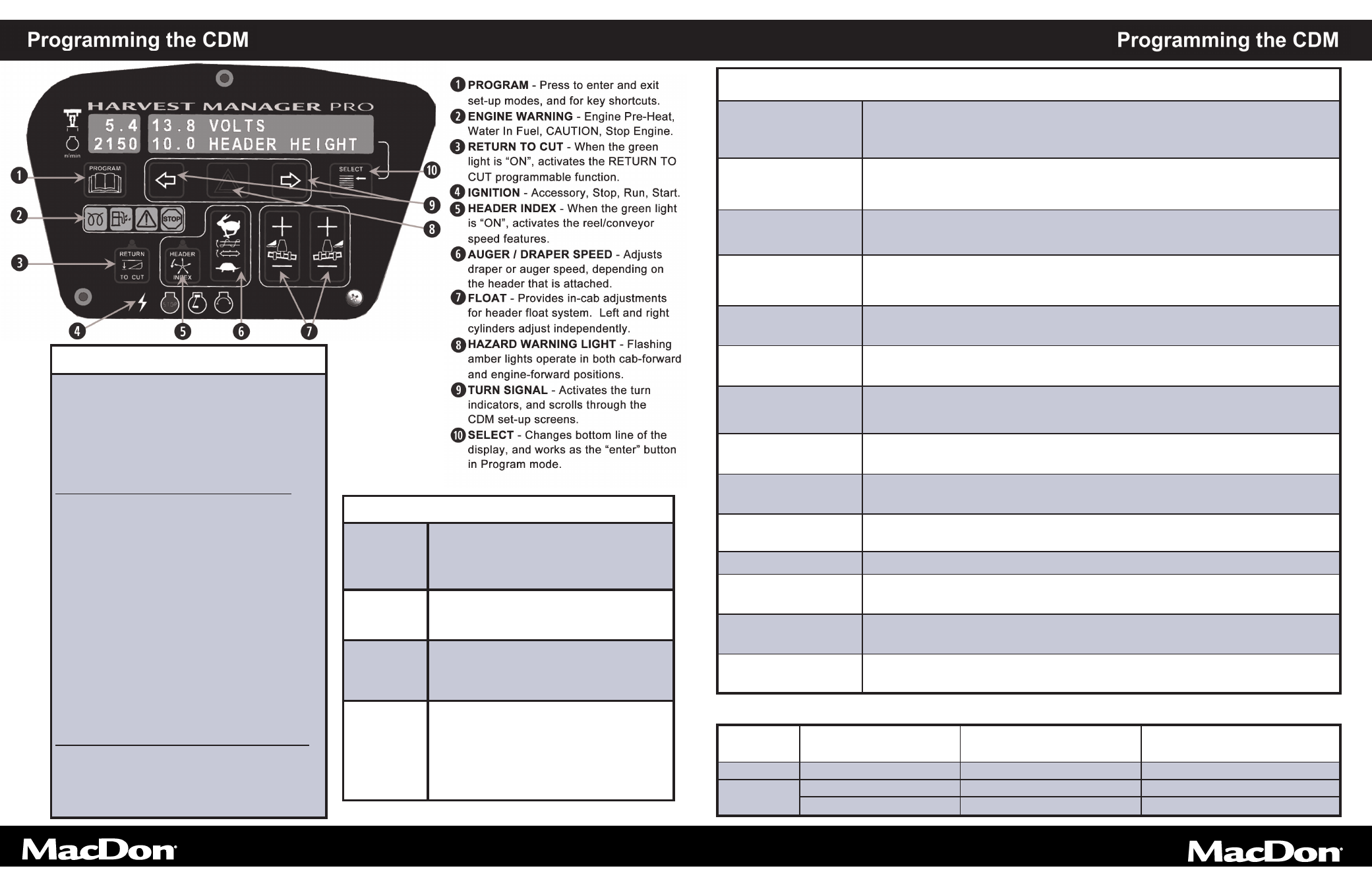

CDM PROGRAMMING MODE: WINDROWER SETUP

SET KNIFE SPEED

SPM

Adjusts knife speed on draper and auger headers.

Every header size and type of knife drive will have a different range for the knife speed.

Refer to your header Quick Card for optimal settings.

KNIFE / DISC OVERLOAD

SPD SPM/RPM

KNIFE OVERLOAD SPEED (Auger/Draper) and DISC OVERLOAD SPEED (Rotary)

Recommended setting is 75% of knife/disc speed.

Range is –100 to –500 SPM/RPM. Default setting is –300 SPM/RPM.

OVERLOAD PRESSURE

PSI/BAR

Calibration of overload sensor (reel/draper/knife/disc system).

See Overload Recommendations Chart below.

HEADER INDEX MODE

Reel+Drapers

OR Reel Only

Auger and Draper headers only.

References and operates Reel Only or Reel and Drapers in relation to ground speed.

RETURN TO CUT MODE

Height+Tilt OR Height Only

Set functions to be controlled by RETURN TO CUT mode.

AUTO RAISE

←10.0→

Sets the header up height in RETURN TO CUT mode.

DWA INSTALLED

YES/NO?

Activates electrical controls for Double Windrow Attachment when installed.

SWAP DWA CONTROLS

NO/YES?

If YES is selected, the REEL FORE-AFT buttons on the GSL and the DWA RAISE/LOWER

switches on the console will swap functions.

HEADER CUT WIDTH

##.# FT/M

Set cut width according to operating width. Calibration of acre counter.

Header ID displayed on CDM at top right.

HDR REEL SPD

RPM or MPH/KMH

Allows REEL SPEED to display in rpm or mph or kph.

SET TIRE SIZE

Select installed tire size for ground speed and acre counter calibration.

SET ENGINE ISC RPM

NO/YES?

ENGINE INTERMEDIATE SPEED CONTROL. Engine rpm can be limited to a specified value

while header is engaged. Scroll to desired rpm value, use HAZARD key to set.

SET CONTROL LOCKS

NO/YES?

Allows header functions to be locked from Operator control

(for example: locking reel speed and/or reel fore-aft controls from Operator.)

VIEW CONTROL LOCKS

NO/YES?

Allows Operator to view control lock status, and engine hours when status was established

(for example: REEL FORE-AFT - 224.5 HRS LOCKED).

TIPS AND SHORTCUTS

Enter

Programming

Mode

Ignition ON.

Press and hold PROGRAM and SELECT at

the same time until the CDM display enters

programming mode.

Exit

Programming

Mode

Press PROGRAM.

Change

Language to

English

Ignition OFF.

Press and hold HEADER INDEX and

PROGRAM and SELECT.

Clear

Sub-Acres

Cab-Forward position.

Ignition ON.

Press SELECT until SUB-ACRES is viewed

on the bottom line of the display.

Press and hold PROGRAM until SUB-ACRES

changes to 0.0.

HEADER

MODEL

APPLICATION/SYSTEM

SUGGESTED OVERLOAD

WARNING SETTING psi (bar)

WINDROWER DIFFERENTIAL

RELIEF SETTING psi (bar)

R-Series

Disc Pressure

5000 (344)

5500 (379)

Reel/Draper Pressure

2500 (172)

2900 (200)

D- and

A-Series

Knife/Conditioner Pressure

3600 (248)

4000 (275)

Enhanced reel/conveyor speed controls may be

desirable in variable crop and terrain conditions.

Allows the reel and conveyor to be driven by

reference to ground speed, so that header systems

will speed up and slow down as ground speed

changes.

Operation of Header Index for REEL SPEED:

(A- and D-Series)

1. With all bystanders clear, start windrower and

engage the header.

2. While stationary and with the GSL in PARK, use

the REEL SPEED control switch to set a

Minimum Reel Speed.

When operating at ground speeds faster than the

Minimum Reel Speed + Header Index value,

REEL SPEED display will change to

REEL INDEX. Using the REEL SPEED switch on

the GSL, Header Index can be adjusted.

Reel speed will be equal to the greater of:

Ground

Speed

+

Index

Value

or

Minimum Reel Speed.

Operation of Header Index for DRAPER SPEED:

(D-Series Only)

Follow instructions above using the CDM AUGER/

DRAPER speed control rather than the GSL REEL

SPEED switch.

HEADER INDEX MODE

M205 Windrower Quick Card - Form 169889 Rev. A

Supplement to M205 Windrower Operator’s Manual - Form 169887

M205 Windrower Quick Card - Form 169889 Rev. A

Supplement to M205 Windrower Operator’s Manual - Form 169887