Precision Turbo and Engine BigStuff3 GEN3 Engine Torque Management (ETM) System User Manual

Page 4

o

MSD 7AL-2

o

MSD 6AL

o

MSD Mag44 points box.

Note: The ETM system, for BigStuff3’s GEN3 coil-on-plug systems (COP), does not

require the ETM module, since all the necessary ETM hardware is resident in the GEN3

ECU.

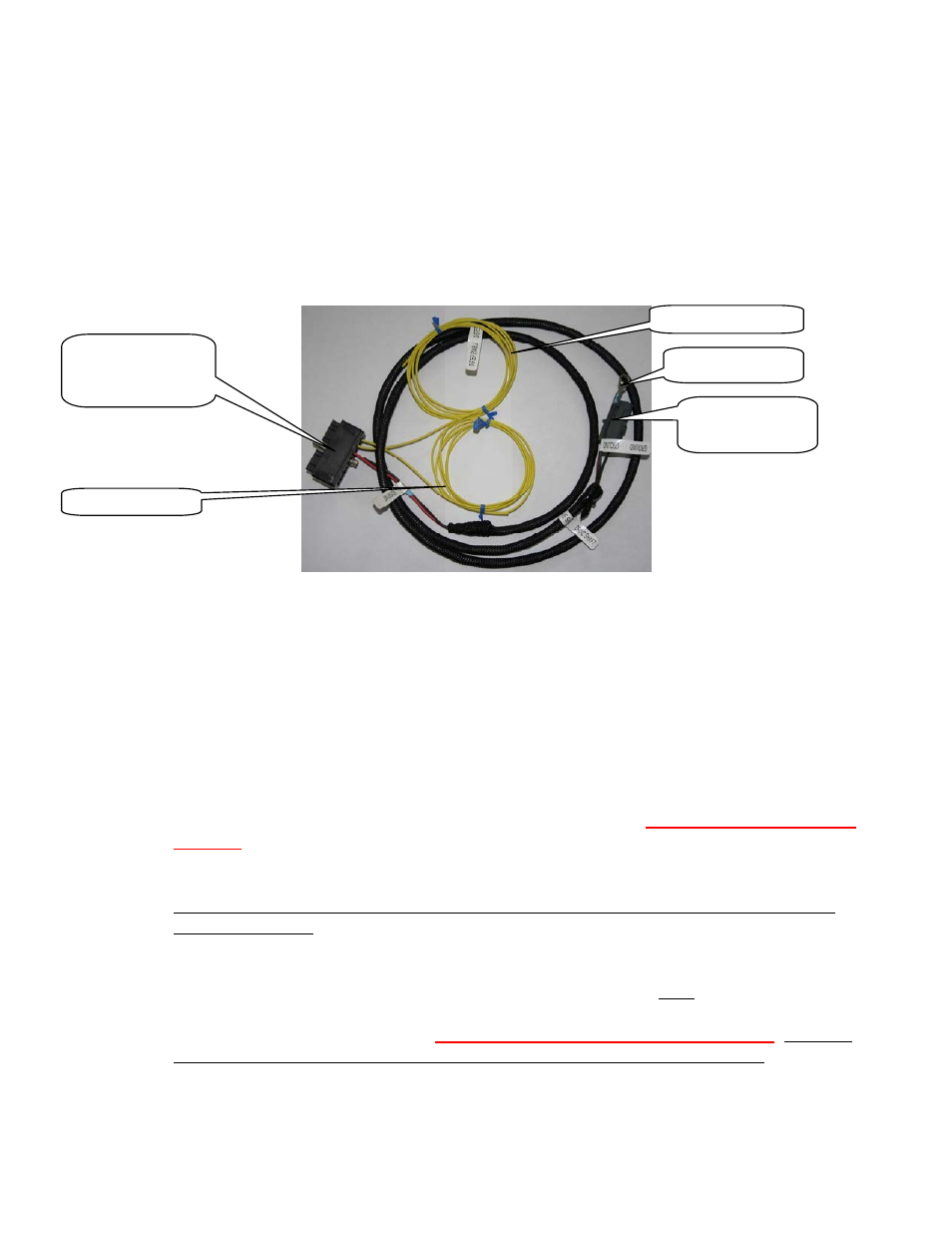

• The ETM Harness

Ground wire

“3-Step Enable” wire

Header connector goes

to GEN3 Header

marked ETM

2-way drive shaft

speed sensor

connector

DAE trigger wire

o

Connect the harness header connector into the GEN3 module header connector marked

“ETM”.

o

Connect the two-way connector labeled “Drive Shaft” to the drive shaft speed sensor (not

supplied with the system). See the “What else is Needed” section above for more details.

Install the 2 way Metri-Pack Packard connector PN 12103784 (w/terminals PN 12089188)

onto the driveshaft sensor and plug it into the ETM harness. If the TOSS trace is erratic

switch the wires!

o

Connect the “Ground” wire to the frame near the drive shaft speed sensor along with the

sensor ground.

o

Connect the DAE trigger Wire (from ECU header connector Hdr2 Y2) to a 12V switched

source.

There must be 12 Volts applied to this wire, for the 2 step and 3 step functions

to work!

o

Connect the 2 Step Enable wire (Hdr1 B2) to the footbrake and /or trans-brake depending

upon options. The 2-step and 3-step functions are independent of each other, except that

when the 3-step is engaged (12 Volts applied to the “3-step Enable” wire) the 3-step will

override the 2-step.

o

Connect the 3 Step Enable wire (Hdr 2 W1, TSS+) to the trans-brake switch. (If you have

this option). If you have the DAE option, the red turbo shaft speed wire in the DAE harness

(also Hdr 2 W1) is used for the 3-step enable function. 12 Volts must be applied to this

wire (via the trans brake, for example) for the 3 step to work.

Also, there must be 12 Volts

applied to the DAE trigger wire, for the 2 step and 3 step functions to work.

When 12

Volts is applied to the “3-step Enable” wire, the 3-step will override the 2-step.

o

Timer Enable wire - connect to a relay to invert the trans-brake signal (see wiring diagram

below). This wire must have12 Volts applied to it once the trans-brake is released to start

the timers in the ECU.

Rev

1.1

4