Fa b, Eatures dvantages enefits – Orbital Research MODULAR AND FLEXIBLE HEAVY ORDNANCE HANDLING SYSTEM User Manual

Page 2

Orbital Research

673 G lpha Park Drive

leveland, OH 44143-2140

A

C

Contact: Frederick J. Lisy, Ph.D.

Telephone (440) 449-5785

E-mail [email protected]

Orbital Research, Inc.

4415 Euclid Ave.

Cleveland, OH 44103

Contact: Frederick J. Lisy, Ph.D.

Telephone (216) 649-0399

E-mail [email protected]

www.orbitalresearch.com

Copyright 2003

Rev RRE 10-24-03

Unified Control System Solution Simulation

In summary

- a simulation

of the control solution algorithm was demonstrated that

represents ORI's core technology. The simulation introduced

increased damping forces into the system. These damping

forces represented either an unexpected increase in payload

weight, friction in the system, actuator performance

degradation, or a near-miss shock event. The simulation

demonstrated how the control solution senses these significant

changes in the system and adapts to maximize system

performance. If for instance a component's performance is

beginning to degrade, the control system recognizes the change

in performance in real time, creates a new model of the system

and continues to perform with essentially no degradation in

performance or at least maximizes the performance given the

nature of the degradation. In a global sense, the system is

capable of recognizing a degraded condition and alerting an

operator that system maintenance or component replacement

is needed. Perhaps the most intriguing capability is its ability to

recognize a near-miss shock condition and to enable a shock

algorithm that would result in a safer mode of operation.

Allowing the system to continue to operate.

Orbital Research Inc successfully demonstrated a

Modular Heavy Ordnance Handling System in fulfillment of a

Phase II Small Business Innovative Research program supported

by the DD-21 program office. This technology has a significant

potential to benefit aircraft carriers as well as other surface

combatants. More importantly, the concepts can be forward or

backfit for Navy material and cargo handling needs. The

potential benefits include.

Tremendous cost savings

Allows for a leaner and robust design

Self tunes for actuator degradation

Self tunes for sensor degradation

Recoverability after near-miss shock

Fault tolerance/isolation

Enables precision placement of object in

dynamic fluctuating environment

,

Orbital Research Inc., established in Cleveland Ohio (1991), is a high technology company. Our corporate mission is to develop and

commercialize innovative solutions for the medical, controls and transportation industries through leveraging our expertise in MEMS devices and

advanced control software. Orbital Research applies these core technologies to solve technical challenges using low cost and commercially viable

solutions.

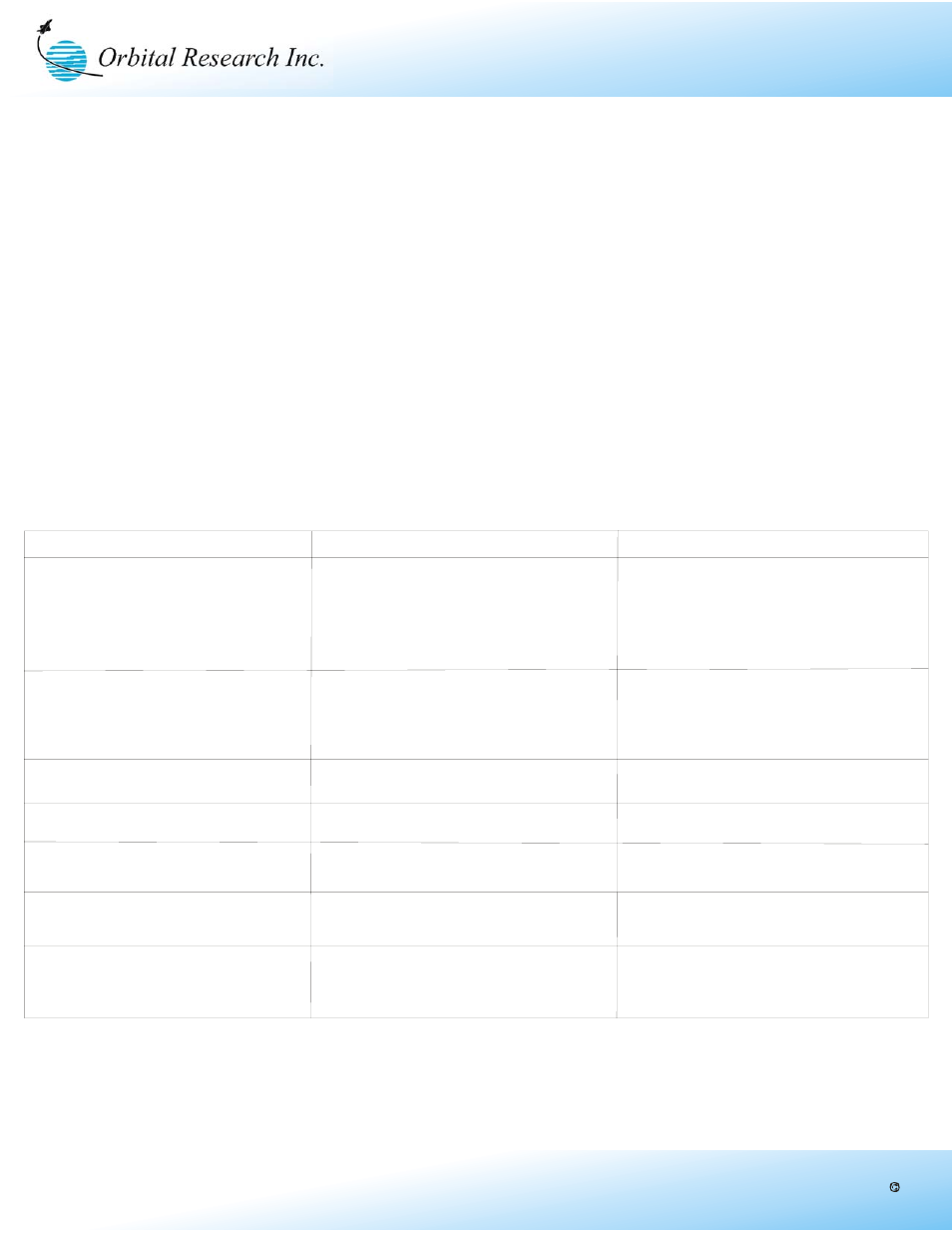

EATURES

DVANTAGES

ENEFITS

F

A

B

Automated System

Minimal personnel required

Reduced manning

Utilize entire weapon magazine

Increased stowage density

Increased material throughput

Reduce total ownership cost

Reduce fatigue induced accidents

Reduce ship underway replenishment time

Unified Control Solution

Multiple ship applications

Custom configured to particular

Software

applications

Less software programming

Cost saving

for hardware applications

Less training

Adaptive and Predictive

Updates its own model

Leaner, lower cost hardware

Software Control

Accommodates degradation

Crash avoidance algorithms

Reflexive collision avoidance

Works with personnel in environment

Emergent behavior algorithms

Coordinate activities among

Less human intervention required to

autonomous vehicles

accomplish tasks

Optimal trajectory control

Plan a path to maneuver from

Expedites material handling by

algorithms

start to finish

avoiding bottlenecks

Modular Hardware

Use on other ship applications

Cost savings

Less training

Sailor familiarity

This work supported by the NAVSEA DD-21 SBIR program. Contract # N00024-98-C-4802