Caution, Sv-series vibrator motor — maintenance – Multiquip SV-SERIES User Manual

Page 14

PAGE 14 — SV-SERIES VIBRATOR MOTOR— PARTS & OPERATION MANUAL — REV. #2 (09/16/02)

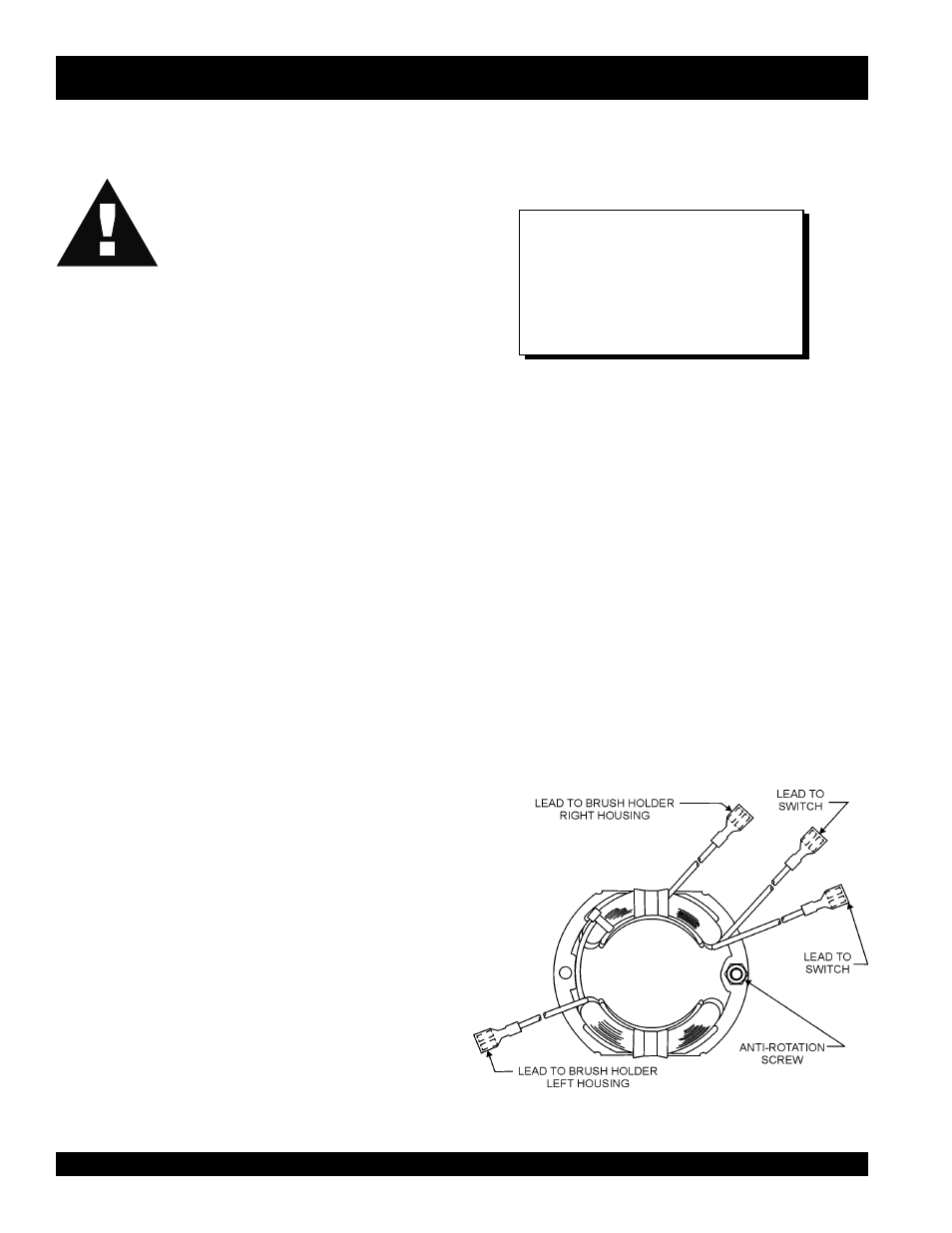

Field Orientation (Figure 5) (when viewed from the rear of

the motor)

MAINTENANCE

CAUTION!

CAUTION!

CAUTION!

CAUTION!

CAUTION!

This is a universal motor and it will run at approximately its rated

speed if the motor and its attached equipment are properly

operated and maintained.

SV-SERIES VIBRATOR MOTOR — MAINTENANCE

Before performing any maintenace on this unit,

ALWAYS MAKE CERTAIN that the switch is

in the "OFF" position and the power cord is

disconnected from the power source.

1.

Have repair work performed by an authorized service

facility, using identical or manufacturer approved

replacement parts.

2.

This motor uses sealed bearings and does not require

lubrication.

3.

Visually inspect the motor daily before use for defective or

missing parts, and have repairs made before use.

4.

Inspect brushes frequently and replace when they become

worn to a length of 3/8".

5.

Keep air inlet and air exit louvers clean and free of concrete

and debris. Failure to do so will result in rapid motor

overheating and parts failure.

6.

Clean air filter as needed. If unit is used in high dust areas,

filter will have to be cleaned more often.

7.

Use wrench to tighten brush caps. The brush cap must be

tight enough that the brush holder does not move.

8.

Should complete disassembly of the motor become

necessary, it will be much easier if all internal components

are built into (Left) housing half P/N 29944-302. Using the

exploded view as a guide, place the anti-rotation pin side

of the field into the slot provided in the -302 housing. See

the end of the maintenance section for proper field

orientation. This anti-rotation pin along with the armature

bearing housings will help align the entire motor. Next,

place (Right) housing half P/N 29944-301 down on top of

the -302 half and snap them together, (the lip around the

housing should "pop" as it aligns). Holding the assembled

halves tightly, flip the entire unit over so that the screws can

be inserted.

9.

The 382V flexible shaft requires cleaning and relubrication

every 100 hours of operation. Refer to 382V flexible shafting

operating instructions for maintenance instructions.

10. Vibrator heads should be inspected and relubricated every

100 hours of operation. Follow the instructions for vibrator

heads.

NOTE

Specification and part number

are subject to change without

notice.

Heat should be used to break down the loctite

while you unthread the head from the shaft.

This will prevent possible damage to the

threads from the loctite.

1.

The field should be positioned so the wires coming out of

the field are have 3 wires coming out of the upper field

shoe and one wire coming out of the lower field shoe.

2.

The 2 long leads from the upper shoe should be routed

through the housing to the switch.

3.

The third shorter lead from the upper shoe should be

connected to the right-hand brush holder when viewed

from the rear of the motor.

4.

The single lead from the lower shoe should be connected

to the left -hand brush holder when viewed from the rear of

the motor.

5.

After assembling complete motor, check the direction of

shaft rotation. When viewed from the front or drive end of

the motor the shaft should turn in a counter-clockwise

direction.

Figure 5. Field Orientation