Sv-series vibrator motor — operation – Multiquip SV-SERIES User Manual

Page 13

SV-SERIES VIBRATOR MOTOR — PARTS & OPERATION MANUAL — REV. #2 (09/16/02) — PAGE 13

SV-SERIES VIBRATOR MOTOR — OPERATION

SV-SERIES VIBRATOR MOTOR OPERATION

Read

all the safety instructions carefully. Safety instructions will

be found throughout this manual and on the Vibrator Motor. Keep

all safety information in good, readable condition.

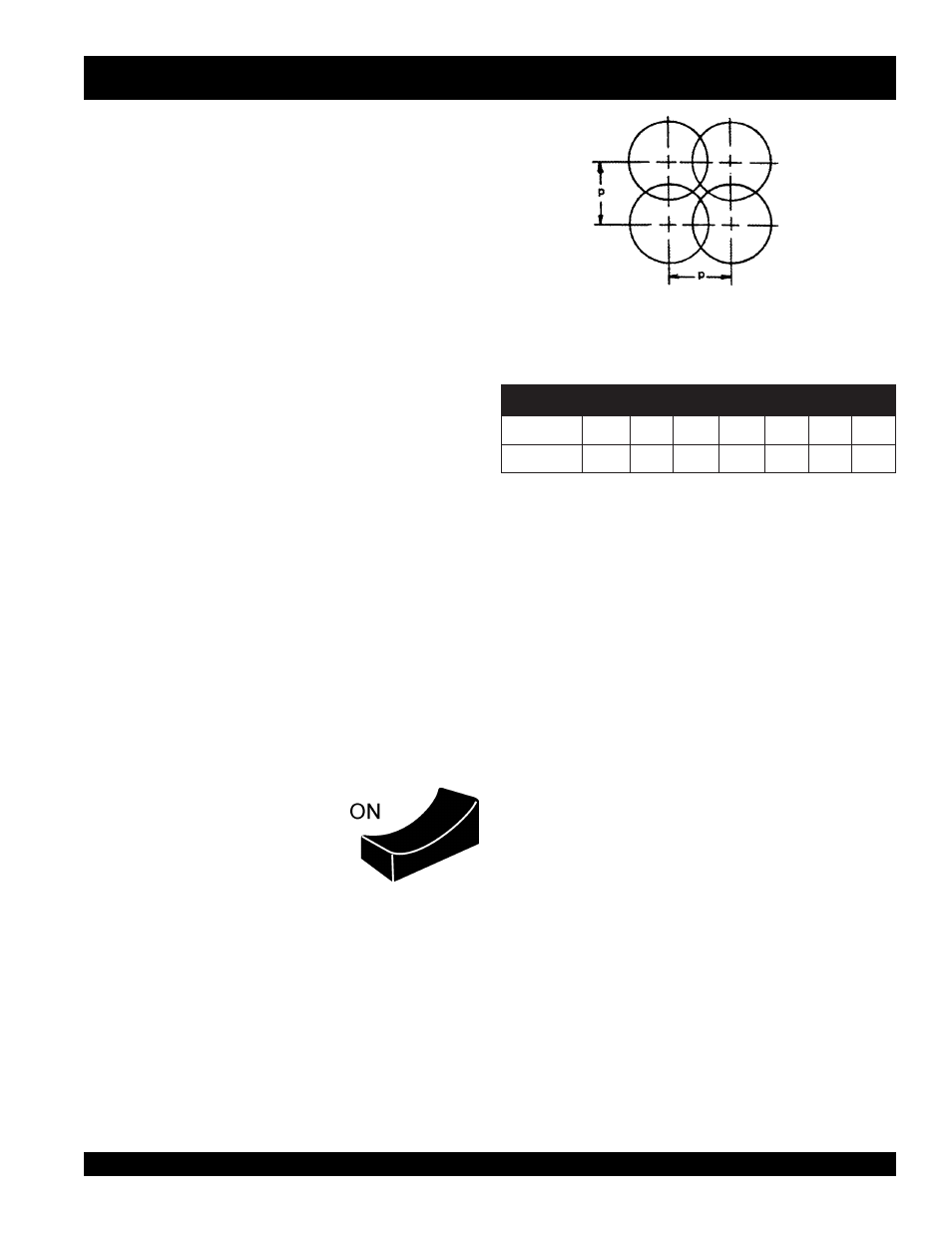

Figure 4. Compaction Coverage

with 50% Radial Overlap

THEORY OF CONCRETE VIBRATION

This

VIBRATOR MOTOR

is designed for the

compaction

of

concrete by removal of air pockets and voids.

The action of vibration is to set the particles in the fresh concrete

in motion, thereby reducing the friction between the particles

and giving the mixture the mobile quality of a thick fluid so that

gravity and the displacement of entrapped air will cause it to

settle easily into place.

By thus consolidating the concrete quickly, "stiffer" or "drier" mixes

can be poured than would otherwise be possible. It has been

proven that (up to a point) the drier the concrete, (that is, the less

water in it), the better the quality throughout and the greater the

strength.

Drier mixes also make the concrete more water tight, increase

resistance to weathering, and create a better bond between

concrete and reinforcement. Because vibration causes much of

the entrapped air in the concrete to rise to the surface,

honeycombing is prevented. Also, vibration eliminates most of

the air pockets between the concrete and the vertical forms.

e

g

a

r

e

v

o

C

n

o

i

t

c

a

p

m

o

C

.

4

e

l

b

a

T

d

a

e

H

0

0

9

0

0

0

1

0

0

3

1

0

0

4

1

0

0

7

1

0

0

1

2

0

0

6

2

n

o

i

s

n

e

m

i

D

-

P

"

4

"

2

/

1

-

5

"

8

"

8

"

2

1

"

4

1

"

8

1

1. Make certain that the flexible shaft is properly attached to

the motor and the head to the flexible shaft.

2. Use the flexible shaft in as straight a position aspossible.

3. DO NOT bend the flexible shaft sharply at any point. Sharp

bends may cause a permanent kink, requiring early

replacement of the flexible shaft.

4. With the Stow vibrator motor properly

plugged into the correct power

source, turn the ON/OFF switch to

the "ON" position and proceed to

insert the vibrator into the cocrete.

5. The concrete is normally placed in the forms in layers about

12 to 18 inches thick in a manner which forms a fairly level

surface. The vibrator head is inserted vertically into the top

of the pile

.

6. DO NOT insert the head into the side of the pile to make the

concrete flow as this practice can cause segregation of the

aggregare from the motar. When the surface has become

fairly level, the head the should be immersed and generally

moved in the patter shown in Figure 4.

7. Immerse the head for 5 to 10 seconds, (until air stops rising),

and then withdraw it slowly to let the concrete fill the void left

by the head.

8. The head shoud be completely below the surface when

vibrating to keep the head cool.

9. When vibrating a thin horizontal slab, the head can be used

in a horizontal position.