Sv-series vibrator motor—preparation & operation, Warning, Caution – Multiquip SV-SERIES User Manual

Page 12

PAGE 12 — SV-SERIES VIBRATOR MOTOR— PARTS & OPERATION MANUAL — REV. #2 (09/16/02)

SV-SERIES VIBRATOR MOTOR—PREPARATION & OPERATION

Before using your Vibrator Motor, read and

fully understand all of the safety and

operating instructions not only for the motor,

but also for the flexible shafting and the head

that will be used with the motor.

1.

The vibrator motor, flexible shafting, and heads are shipped

from the factory ready to use. Connect per instruction

bulletins.

2.

Use only the combination of flexible shafting and heads

shown below in Table 3.

3.

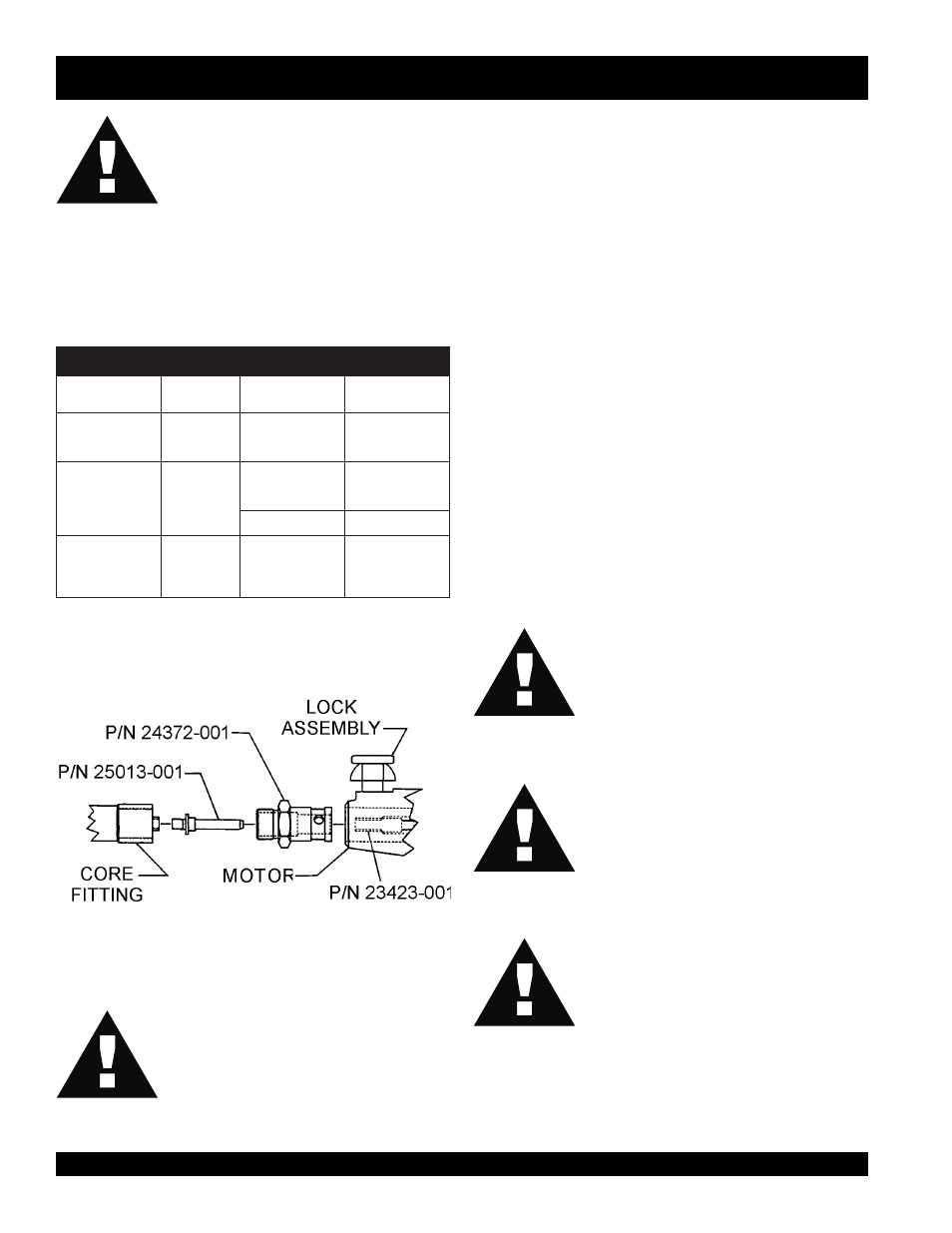

To connect the 382V flexible shafting to the vibrator motor

see (Figure 3).

Figure 3. Shafting to Motor Connection

WARNING!

WARNING!

WARNING!

WARNING!

WARNING!

MAKE CERTAIN the motor is disconnected

from the power source and the switch is in the

"OFF" position.

CAUTION!

CAUTION!

CAUTION!

CAUTION!

CAUTION!

If the shaft begins to helix (buckle) excessively

during operation, stop and investigate. This is

an indication of an overload condition.

CAUTION!

CAUTION!

CAUTION!

CAUTION!

CAUTION!

The vibrator head is cooled by the concrete.

Operation of the vibrator head in air longer

than 2 minutes at a time will cause overheating

of the bearings which will result in premature

head failure.

CAUTION!

CAUTION!

CAUTION!

CAUTION!

CAUTION!

Visually inspect the air intake and exhaust

frequently to make sure the motor has sufficient

air for cooling.

s

e

z

i

S

t

f

a

h

S

.

3

e

l

b

a

T

L

E

D

O

M

T

F

A

H

S

E

Z

I

S

D

A

E

H

T

F

A

H

S

.

X

A

M

H

T

G

N

E

L

1

-

V

S

V

4

1

3

0

0

9

0

0

0

1

0

0

3

1

.

T

F

1

2

2

-

V

S

V

2

8

3

0

0

4

1

0

0

7

1

.

T

F

8

2

0

0

1

2

.

T

F

1

2

3

-

V

S

V

2

8

3

0

0

4

1

0

0

7

1

0

0

1

2

0

0

6

2

.

T

F

5

3

4. Slide the core out of the casing far enough to thread the

spindle (p/n 25013-001) into the core fitting and tighten. A

pair of pliers and a wrench can be used to tighten

theconnection. It is important that this connection be tight. If

it is not, the torque of the motor plus the load of the head will

jam the two fittings together making it extremely hard to

loosen them for disassembly.

5. Thread the shaft coupling (P/N 24372-001) into the casing

ferrule and tighten.

6. Pull up on the lock pin and slide the shaft assembly into the

front motor bearing housing and release the lock pin. Give

the shaft assembly a twist to make sure that the lock pin is

seated in one of the 3 tapered holes in the shaft coupling.

7. Clean the mating parts threads with Locquic Primer "T".

Allow to dry several minutes before applying a ring of Loctite

No. 271 or equivalent to the middle of thecasing threads.

Screw the head tightly to the casing and wait 1 hour before

using. Threads are left-hand; turn counter-clockwise to

tighten.