Maintenance – Multiquip J36S60 User Manual

Page 32

page 32 — J36S60 WaLK-BeHIND TROWeL • OpeRaTION aND paRTS maNUaL — Rev. #1 (01/23/13)

Maintenance

SpaRK aRReSTeR CLeaNINg

Clean the spark arrester every 6 months or 100 hours.

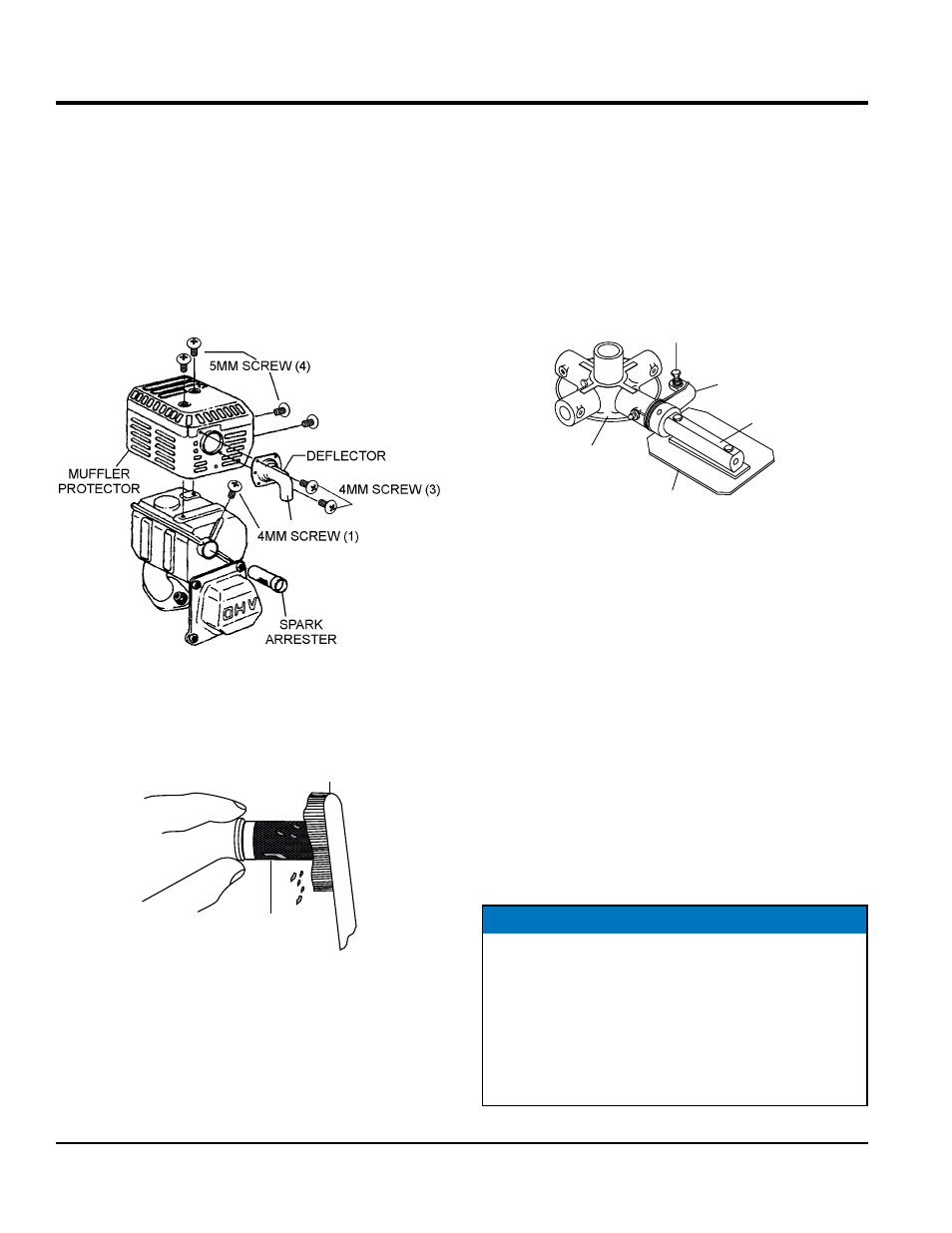

1. Remove the 4 mm screw (3) from the exhaust deflector,

then remove the deflector. See Figure 46

2. Remove the 5 mm screw (4) from the muffler protector,

then remove the muffler protector.

3. Remove the 4 mm screw from the spark arrestor, then

remove the spark arrester.

Figure 46. Spark Arrester Removal

4. Carefully remove carbon deposits from the spark

arrester screen (Figure 47) with a wire brush.

Figure 47. Cleaning The Spark Arrester

5. If the spark arrester is damaged and has breaks or

holes, replace with a new one.

6. Reinstall the spark arrester and muffler protector in

reverse order of disassembly.

SPARK

ARRESTER

SCREEN

WIRE

BRUSH

BLaDe pITCH aDJUSTmeNT pROCeDURe

The maintenance adjustment of blade pitch is an adjustment

that is made by a bolt (Figure 48) on the arm of the trowel

arm lever. This bolt is the contact point of the trowel arm

lever to the lower wear plate on the thrust collar. The goal

of the adjustment is to promote consistent blade pitch and

finishing quality. Adjustments are made by tightening or

loosening the blade pitch adjustment bolt.

Figure 48. Blade Pitch Adjustment Bolt

Watch for the following indications when determining if

blade pitch adjustments are necessary:

• Is the machine wearing out blades unevenly, (i.e. one

blade is completely worn out while the others look

new)?

• Does the machine have a perceptible rolling or

bouncing motion when in use?

• Look at the machine while it is running, do the guard

rings “rock up and down” relative to the ground?

If it is determined that blade pitch adjustments are required

do the following:

1. Place the trowel on a flat, level area free of dirt and

debris.

SPIDER

PLATE

BLADE PITCH

ADJUSTMENT

BOLT

TROWEL

ARM

TROWEL LEVER

FINGER

TROWEL

BLADE

NOTICE

Before any blade pitch adjustments can be made it

is essential to have a clean level area free of dirt and

debris to test the trowel. Any unlevel spots in the floor

or debris under the trowel blades will give an incorrect

perception of adjustment. Ideally, a 5 x 5 ft. (1.5 x 1.5

meter), three-quarter inch (19 mm) thick

FLaT steel

plate should be used for testing.