Inspection, Pre-load adjustment (quick pitch™ handle only), Before starting – Multiquip BS46HLE User Manual

Page 19: Engine oil check

BS46H SeRIeS WaLK-BeHIND TROWeL • OpeRaTION aND paRTS maNUaL — Rev. #2 (10/15/13) — page 19

inspection

5. Insert the cable end through the yoke eyelet

(Figure 13). Tighten brass set nut #1 by hand to remove

all the slack from the cable.

Figure 13. Pitch Cable Yoke Attachment

6. Using a wrench, tighten the brass set #2 nut up against

the yoke boss. This will lock the cable in place.

7. Use a wrench and finish tightening the brass set #1

nut up against the yoke boss.

pre-Load adjustment (Quick pitch™ Handle Only)

1. After the Quick-Pitch™ handle has been installed on

the trowel, spring pre-load adjustment will be required.

2. Locate the spring pre-load adjustment screw (Figure 14)

on the underside of the handle tube.

Figure 14. Spring Pre-Load Adjustment

BLADE

PITCH

CABLE

YOKE

YOKE

EYELET

BRASS SET

NUT #1

BRASS SET

NUT #2

warNiNg

The Quick Pitch™ handle is spring loaded, personal

injury or damage could result from improper handling,

installation or adjustment. Use extreme caution when

installing this component.

ADJUSTMENT

SCREW

SLIDER

GROOVE

FINISH

36”

COMBO

PRELOAD TRIM INDICATOR

FINISH

48”

COMBO

FINISH

J

COMBO

FINISH

B

COMBO

F

IN

IS

H

36”

C

O

M

B

O

PRELOA

D

TRI

M

INDIC

AT

OR

F

IN

IS

H

48”

C

O

M

B

O

F

IN

IS

H

J

C

O

M

B

O

F

IN

IS

H

J

C

O

M

B

O

ALIGNMENT

DECAL

3. A decal has been placed on the side of the handle

tube to assist the user in the adjustment of the spring.

4. Align the groove on the slider with the text 48" COMBO/

"B" COMBO on the decal.

before Starting

1. Read all safety instructions at the beginning of manual.

2. Clean the trowel, removing dirt and dust, particularly

the engine cooling air inlet, carburetor and air cleaner.

3. Check the air filter for dirt and dust. If air filter is dirty,

replace air filter with a new one as required.

4. Check carburetor for external dirt and dust. Clean with

dry compressed air.

5. Check fastening nuts and bolts for tightness.

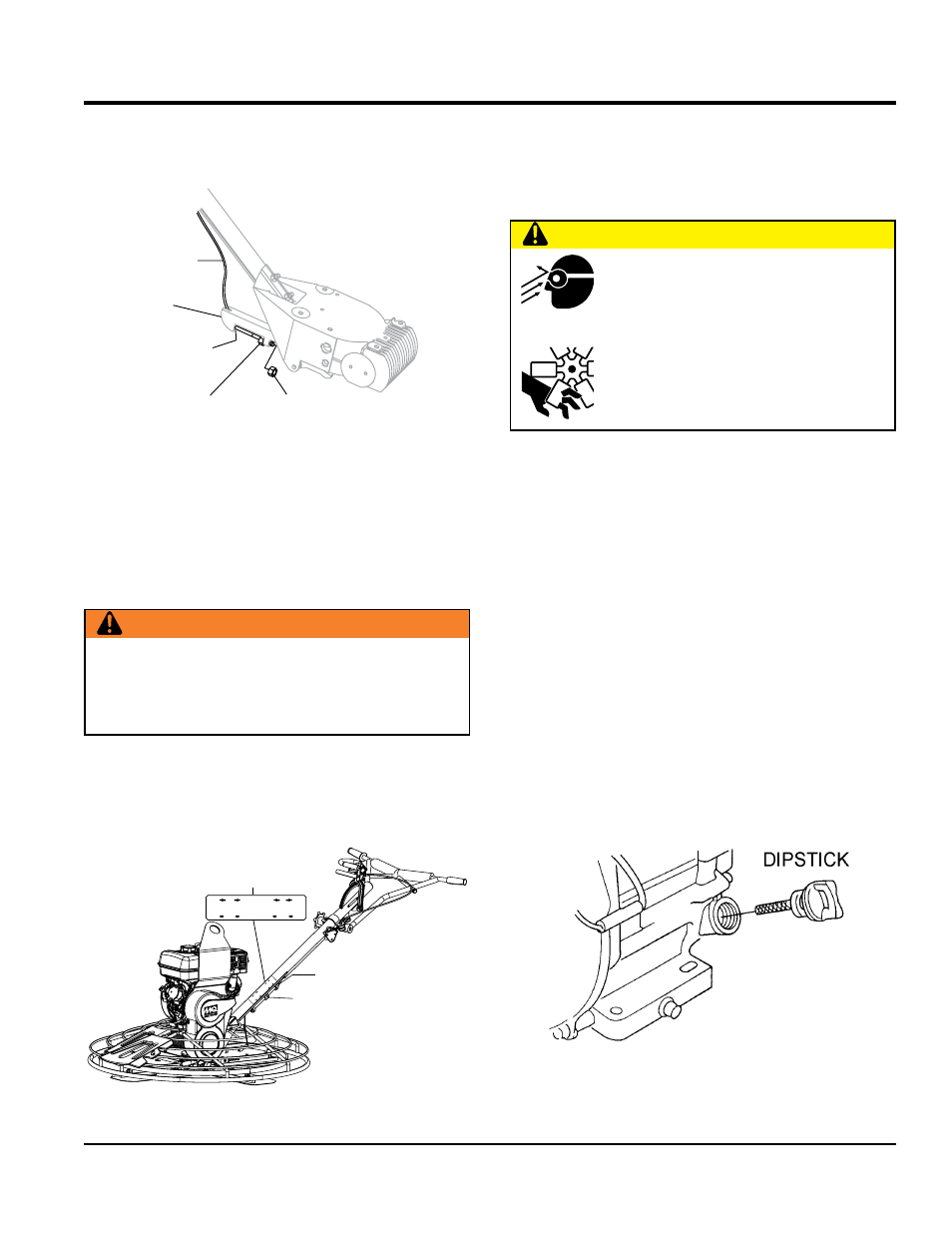

Engine Oil check

1. To check the engine oil level, place the trowel on secure

level ground with the engine stopped.

2. Remove the dipstick from the engine oil filler hole

(Figure 15) and wipe clean.

Figure 15. Engine Oil Dipstick Removal

CaUTION

aLwayS wear approved eye and hearing

protection before operating the trowel.

NeveR place hands or feet inside the guard

rings while the engine is running.

aLwayS

shut the engine down before performing any

kind of maintenance service on the trowel.