Sdw-225ss— welder operating instructions – Multiquip SDW225SS User Manual

Page 34

PAGE 34 —SDW-225SS WELDER/GENERATOR— OPERATION & PARTS MANUAL — REV. # 2 (10/07/05)

SDW-225SS— WELDER OPERATING INSTRUCTIONS

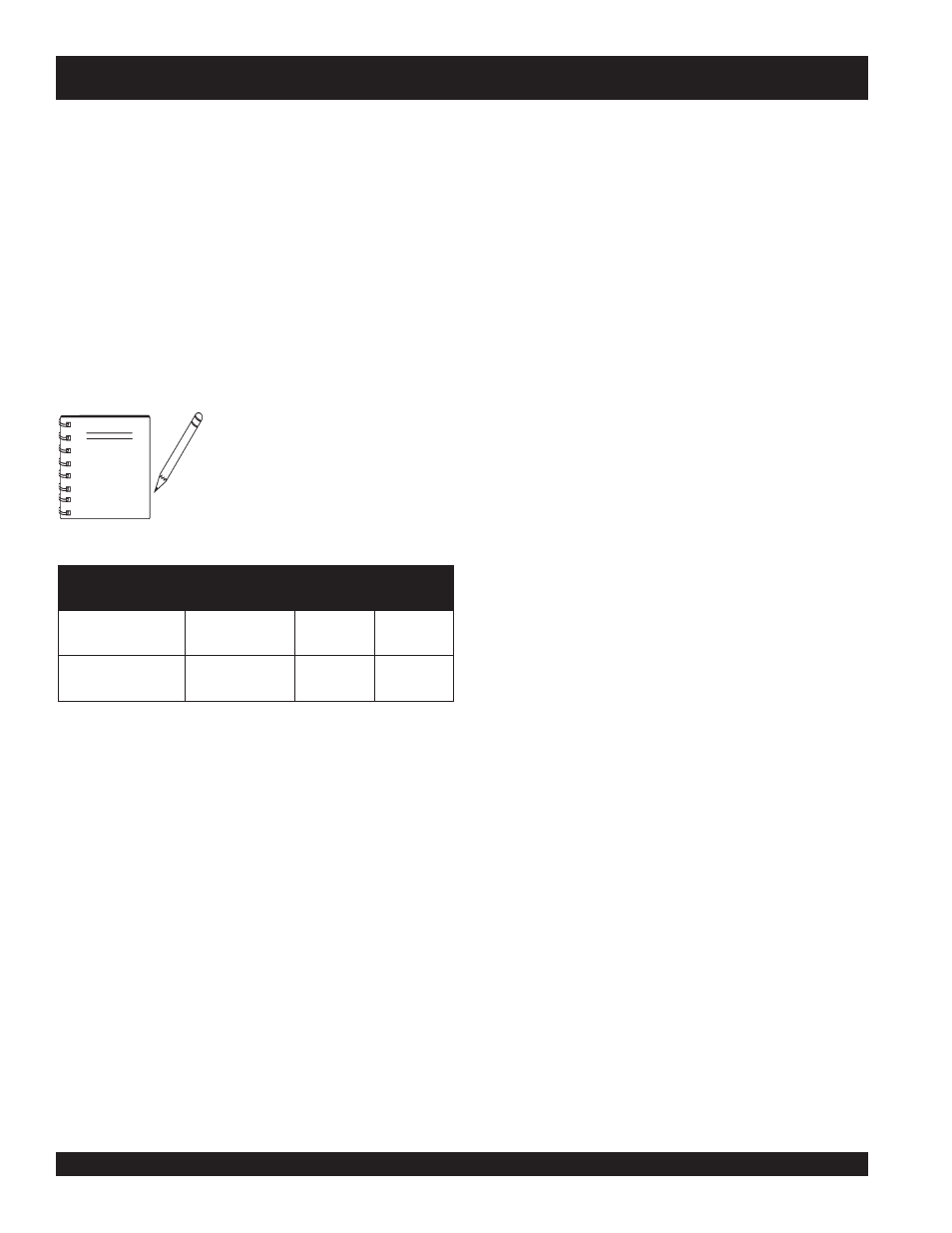

Duty Cycle

The welder is rated at 100% duty cycle at 200 amps.

However the duty cycle depends upon the welding

current. Select the appropriate duty cycle from Table 12

to prevent overload.

Welding and Auxiliary Outputs.

The welding and auxiliary outputs can be used simultaneously,

subject to all of the following conditions:

z CC/CV Selector Switch is in the CC mode.

z CC Current Range Selector is in the low mode.

z Current Control is in the MAX position.

e

l

c

y

C

y

t

u

D

.

2

1

e

l

b

a

T

)

%

(

e

l

c

y

C

y

t

u

D

0

0

1

0

8

0

6

)

s

p

m

A

(

t

n

e

r

r

u

C

s

s

e

l

r

o

0

0

2

5

2

2

0

5

2

Quality Welding Check Points

Adherence to the following rules will ensure quality welds.

■ Use only high-quality welding machines, electrodes and

welding accessories.

■ Know the base material you are working on.

■ Select the proper welding process to give the highest

quality welds on the base material to be used.

■ Select the proper welding procedure to meet the service

requirement.

■ Select the correct electrode for the job.

■ When preheating is specified or required, make sure the

temperature requirements are met. In any case, do not

weld on material below 32 °F without first preheating.

■ Clean the base metal of all slag, paint, grease, oil,

moisture and any other foreign materials.

■ Remove weld slag and thoroughly clean each bead prior

to making the next bead or pass.

■ Do not weld over cracks or porous tack welds. Defective

tack welds should be removed prior to welding.

■ Be particularly alert to obtain root fusion on the first pass

of fillet and groove welds.

■ When root gaps of groove welds are excessive, build up

one side of the joint prior to welding the pieces together.

■ When the root gap is excessive in fillet welding, be sure

to increase the size of the fillet weld to the amount of the

root gap in order to maintain the strength requirement.

In some cases it is advantageous to make a groove

weld in order to avoid extremely large fillets.

■ Inspect your work and immediately replace any defective

weld.

■ Observe the size requirement for each weld to ensure

you meet or slightly exceed the specified size.

■ Make sure the finished appearance of the weld is smooth

and that all overlaps and undercuts are repaired properly.

The strength of a weld should not be judged merely by

its external appearance.

NOTE

The 250 amp, 60% duty cycle

referenced in Table 12 is for CV

welding ONLY.