Operation – Multiquip ST3020BCUL User Manual

Page 21

st3020b1/bCUL sUb. pUmp • operation and parts manUaL — rev. #2 (10/28/10) — page 21

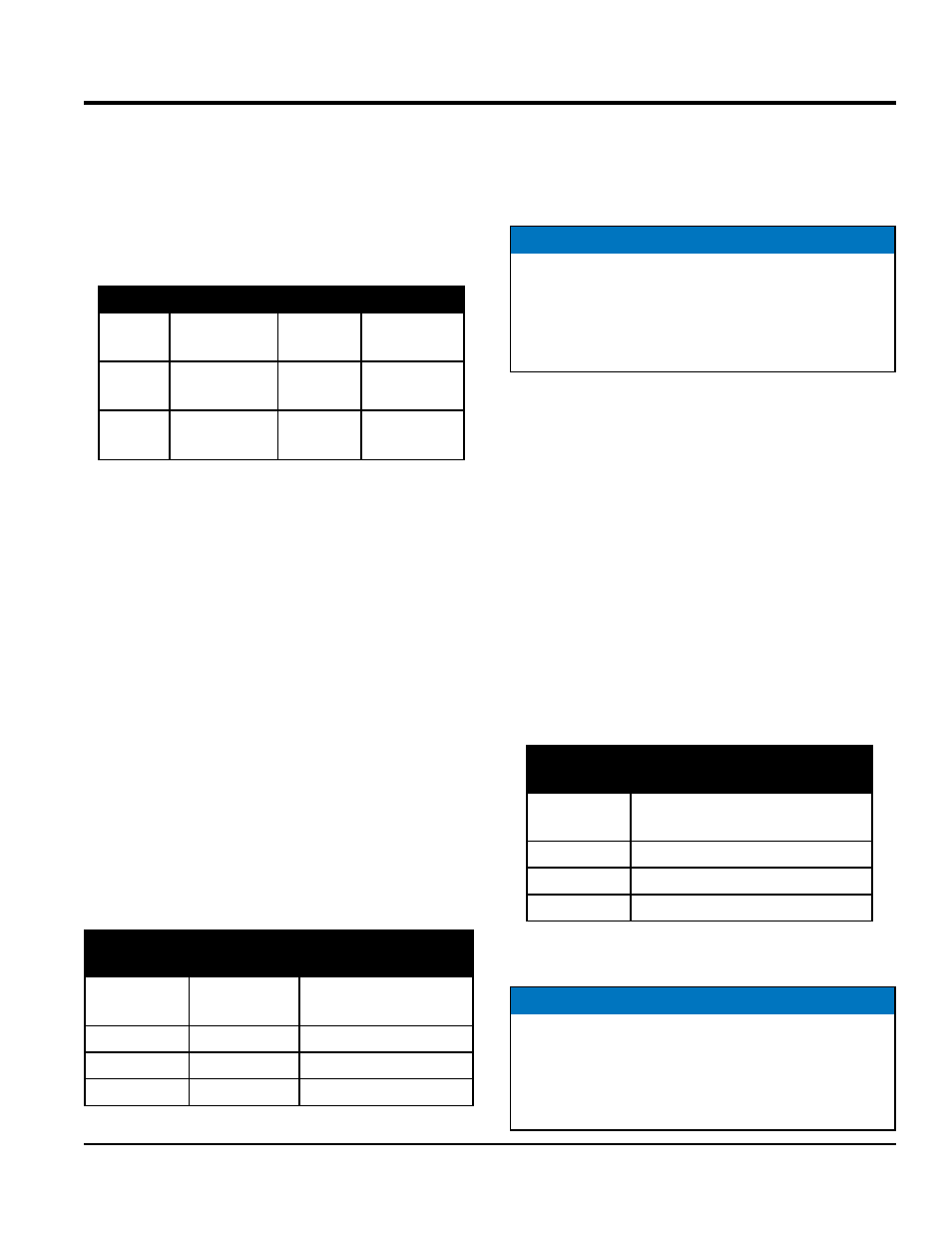

Connecting dual float switch (sW-1Wop) to

Control box

1. Remove the float switch input connector housing, then

route the float switch wires through the cable gland on

the control box. Attach the wires of the float switch to

the terminal block as indicated by Table 5 and Figures

7, 8 and 9.

2. Tighten the connector housing to ensure a tight fit

between the cord and the connector body. This will

prevent the cable from pulling out of the terminal block

and also prevent moisture from entering the control box.

3. Determine the tether length of the float switch wires

then secure float switch wires to pump discharge hose.

See Figure 8 and Table 3 to determine the pumping

range.

Connecting aC power to the Cb 200 Control box

1. The AC power cord (input) should have three wires.

Each wire is color coded. The colors are

red, BLACK

and

green.

2. Remove the AC input connector housing from the

control box, then route the power cord through the

cable gland on the control box.

3. Connect the AC power cord to the terminal block (TB1)

located inside the control box as shown in Figures 9,

10, 11 and Table 6.

Table 5. dual Float switch Connections

Float

Switch

Terminal

block no.

Wire

Color

Control

box

Start

TB1-A1

TB1-A2

Black

White

CB6/CB200

Stop

TB1-A3

TB1-A4

Black

White

CB6/CB200

Table 6. 1Ø-230 vaC power

Connections

Wire

Color

CB6 Terminal

block no.

CB200 Terminal

block no.

BLACK

TB1-AR (L1)

TB1A-L1

RED

TB1-AS (L2)

TB1A-L2

GREEN

TB1-GND

TB1-GND

OperatiOn

4. Connect the other end of the AC power cord to the

voltage source. Remember to provide a means of

disconnecting the power from the control box (circuit

breaker or quick disconnect switch). Also make sure

to provide a good earth ground to the control box

Connecting AC Power to the Pump Motor

1. AC power is routed to the pump motor via a contactor/

thermal overload unit. The coil of the contactor is

energized or de-energized by the opening and closing

of the float switch contacts. The thermal overload unit

protects the windings of the electric motor in the event

of a stuck impeller.

2. The power cord should have three wires. Each wire is

color coded. The colors are

red, BLACK and green.

3. Remove the pump AC input connector housing from

the control box, then route the power cord through the

cable gland on the control box.

4. Connect pump power cord to the thermal overload unit

and TB1 as shown in Figures 8, 9 and Table 7.

5. Install

jumper wire between T2 of electronic overload

module and TB1-L3. Reference Figures 10 and 11.

NOTICE

It is recommended that the power being supplied to the

control box

aLWaYs be connected to a circuit breaker

or a

quick disconnect switch. This safety feature

allows for quick removal of power from the control box

in the event of an emergency.

table 7. 1Ø-230 vaC power

Connections

Wire

Color

Cb200 thermal overload Unit

Terminal Block TB1

BLACK

T1-2 (L1)

RED

T3-6 (L3)

GREEN

TB1-GND

NOTICE

CB6 control box does not have thermal overload

capability. Install jumper wire (CB200 Control Box)

between T2 of electronic overload module and TB1-L3.

Jumper wire

must be installed in order for electronic

overload module to work correctly.