Routine maintenance overview checklist, Routine maintenance overview checklist 66 – MTS Insight Material Testing Systems User Manual

Page 66

MTS Insight™ Material Testing System

66

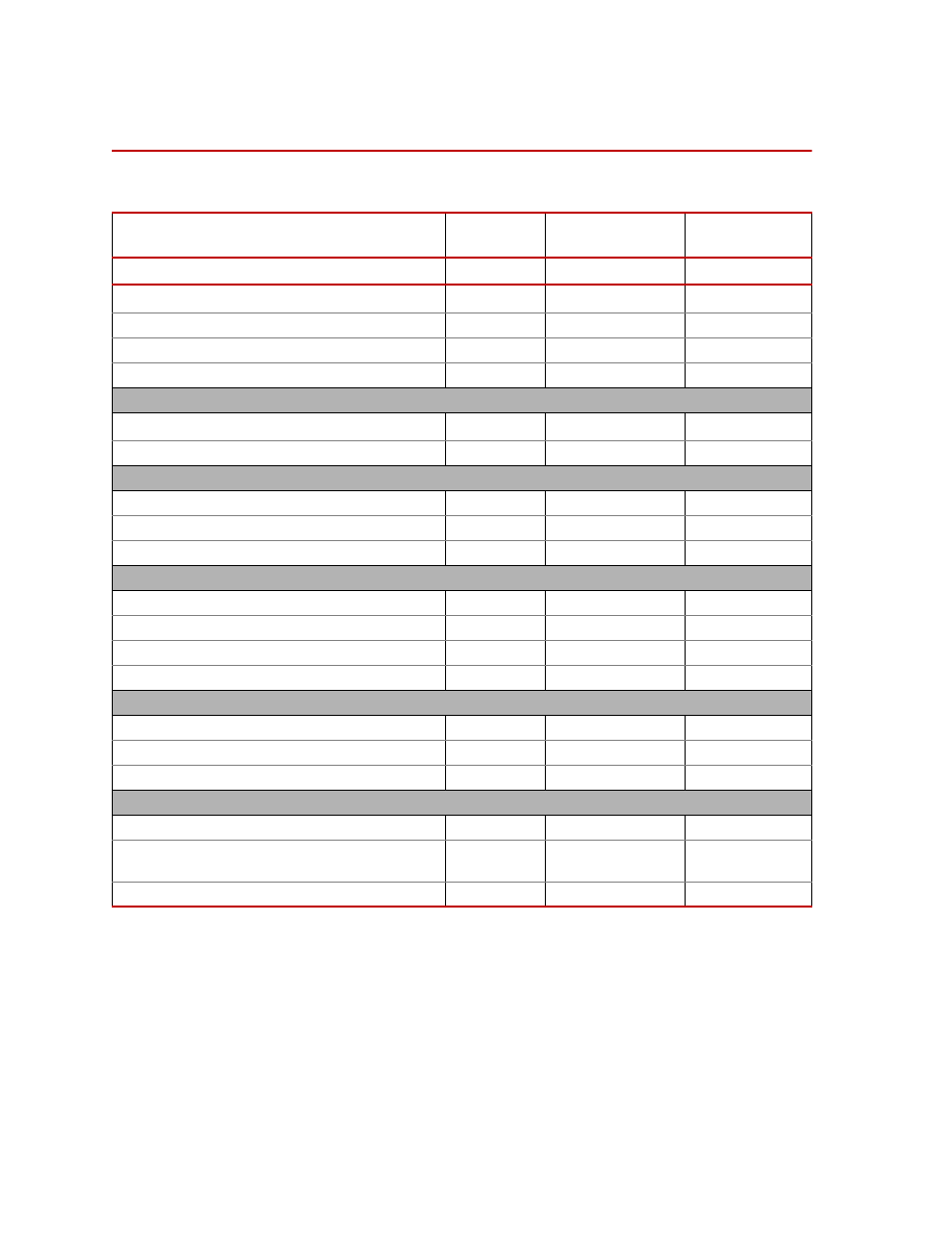

Routine Maintenance Overview Checklist

Maintenance

Routine Maintenance Overview Checklist

Recommended service to be performed at each running time interval noted

Calendar Time using 8 hour Running Time rate per

day

Daily

Weekly

Annually

Running Time-Hours

8

40

2000

Shunt Cal Check

X

*

*Symbol denotes services performed by equipment operators. Most of these procedures involve visual checks

that should not interfere with test system operation. These checks are also completed by trained field service

engineers on each Routine Maintenance visit.

Clean Work Area/Machine Surface

X

Verify Limits and E-Stop

X

Inspect Cable/Connections

X

PC Maintenance

Back-up TestWorks files (*.reg/.cal files)

MTS

†

†Symbol denotes service performed by trained field service engineers as part of an MTS Routine Maintenance

plan. Some of these procedures require special service tools and/or specific service training to complete.

HD Defragmentation

MTS

System Inspection

Inspect/Clean Controller

MTS

Inspect Drive Belts for Excessive Wear

MTS

Inspect Cable Connections

MTS

System Checks

Check E-Stop

MTS

Check Upper Limit

MTS

Check Lower Limit

MTS

Check Load Cal/Shunt Cal

MTS

Lubrication

Crosshead/Ball Screw (#2 white lithium grease)

MTS

Bearings in Base Plate (#2 white lithium grease)

MTS

Drivetrain Bearings (if applicable)

MTS

Frame and Work Area

Clean/Replace Air Filter

MTS

Clean Guide Columns with WD40 (D/G/S Series

Frames)

MTS

Clean Off Frame and Work Area

MTS