MK Diamond MK-VTS-50 User Manual

Page 18

18

MK-VTS/50 FLOOR SCRAPER

MAINTENTANCE

MAINTAINING EQUIPMENT

Keep equipment in good repair by adopting a regular maintenance program. Before use, examine

the general condition of equipment. Inspect guards, switches, tool cord set and extension cord for

damage. Check for loose screws, misalignment, binding of moving parts, improper mounting, broken

parts and any other condition that may affect its safe operation. If abnormal noise or vibration occurs,

turn the tool off immediately and have the problem corrected before further use. Do not use a dam-

aged tool. Tag damaged tools “DO NOT USE” until repaired. See Repairs.

• Mechanical inspection

• Cleaning (pulleys, spindles, bearings, housing, etc.)

• Electrical inspection (switch, cord, plugs, etc.)

• Testing to assure proper mechanical and electrical operation

• Check nuts on shock absorbers and bottom plate for tightness

• Check screws on bottom bearing for tightness

• Check all screws and fittings for a tight and secure fit

• Keep a sharp blade in machine for optimum performance

CLEANING

Clean dust and debris from vents. Keep the Equipment handle clean, dry and free of oil or grease.

Use only mild soap and a damp cloth to clean since certain cleaning agents and solvents are harm-

ful to plastics and other insulated parts. Some of these include: gasoline, turpentine, lacquer thinner,

paint thinner, chlorinated cleaning solvents, ammonia and household detergents containing ammonia.

Never use flammable or combustible solvents around tools. Machine is pressure washable. Make

sure machine is dry before operation.

Interruption of motor operation caused by the thermal switch indicates the existence of improper or insuf-

ficient power to your electric motor. DOUBLE CHECK YOUR POWER SOURCE!

NOTICE

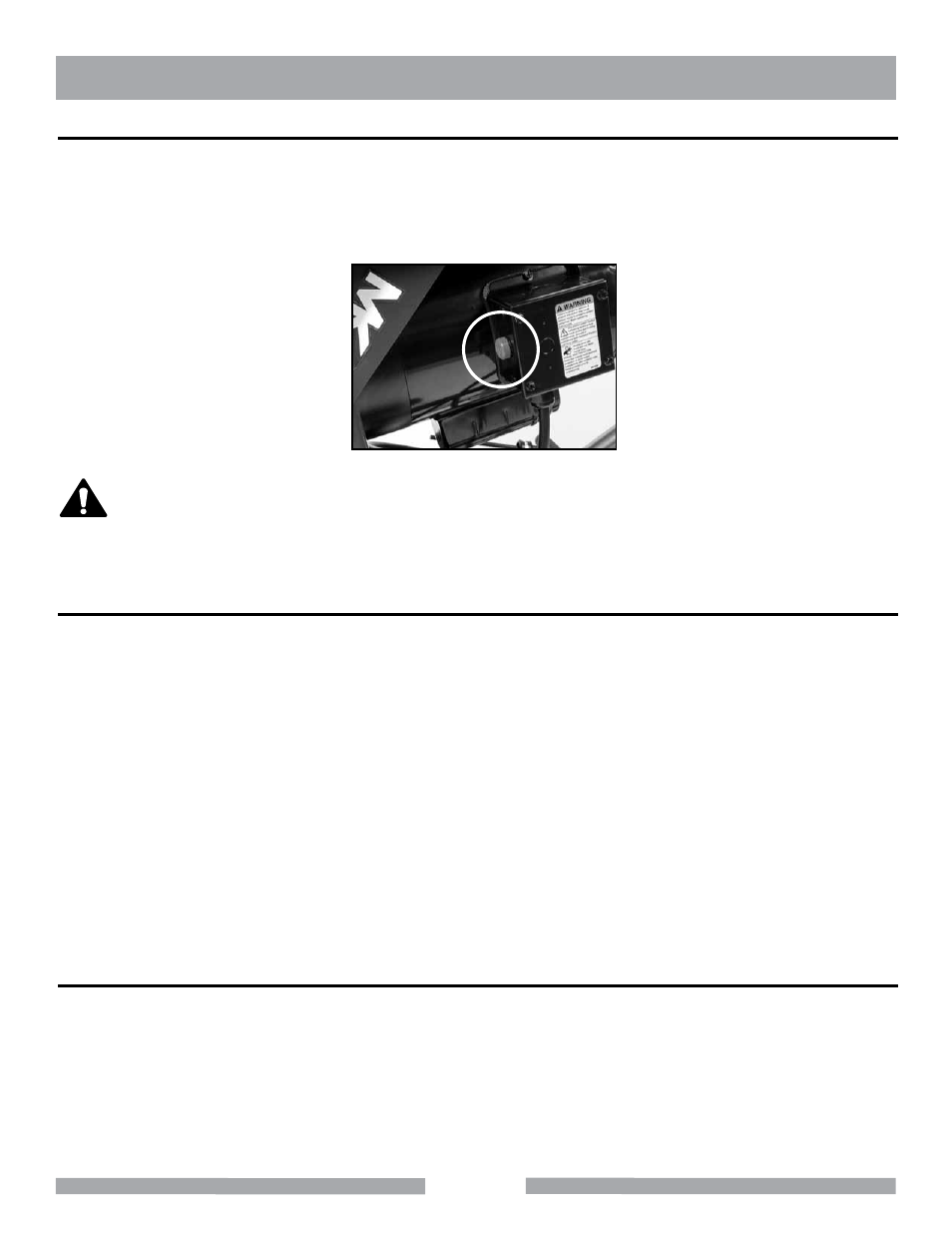

Thermal Overload Switch

The Thermal Overload manual reset switch is located on the bottom of the connection box of the elec-

trical motor. If an extreme internal temperature is sensed, the switch will “trip” and the motor will shut

off automatically. If this occurs, turn the motor “ON/OFF” switch to the “OFF” position and allow the

motor to cool for at least ten minutes before restarting. Push the “reset” button (using minimal force)

and resume operations.

THERMAL OVERLOAD PROTECTION