New Buck Corporation DV1000 User Manual

Page 29

VENTING SYSTEM

Periodic examination of venting systems by a qualified agency.

1. Check areas of venting system that are exposed to the weather for corrosion (rust spots or streaks

and, in extreme cases, holes). Have these items replaced immediately by a qualified service person.

2. Remove the vent cap and shine a flashlight into the vent. Remove any foreign material.

3. Check for evidence of excessive condensation. Continuous condensation can cause corrosion of

caps, pipes, and fittings and can be caused by having excessive lateral runs, too many elbows, or

exterior portions of the system being exposed to cold weather.

4. Inspect joints to verify that no pipe section or fitting has been disturbed and loosened. Check me-

chanical supports such as wall straps for rigidity.

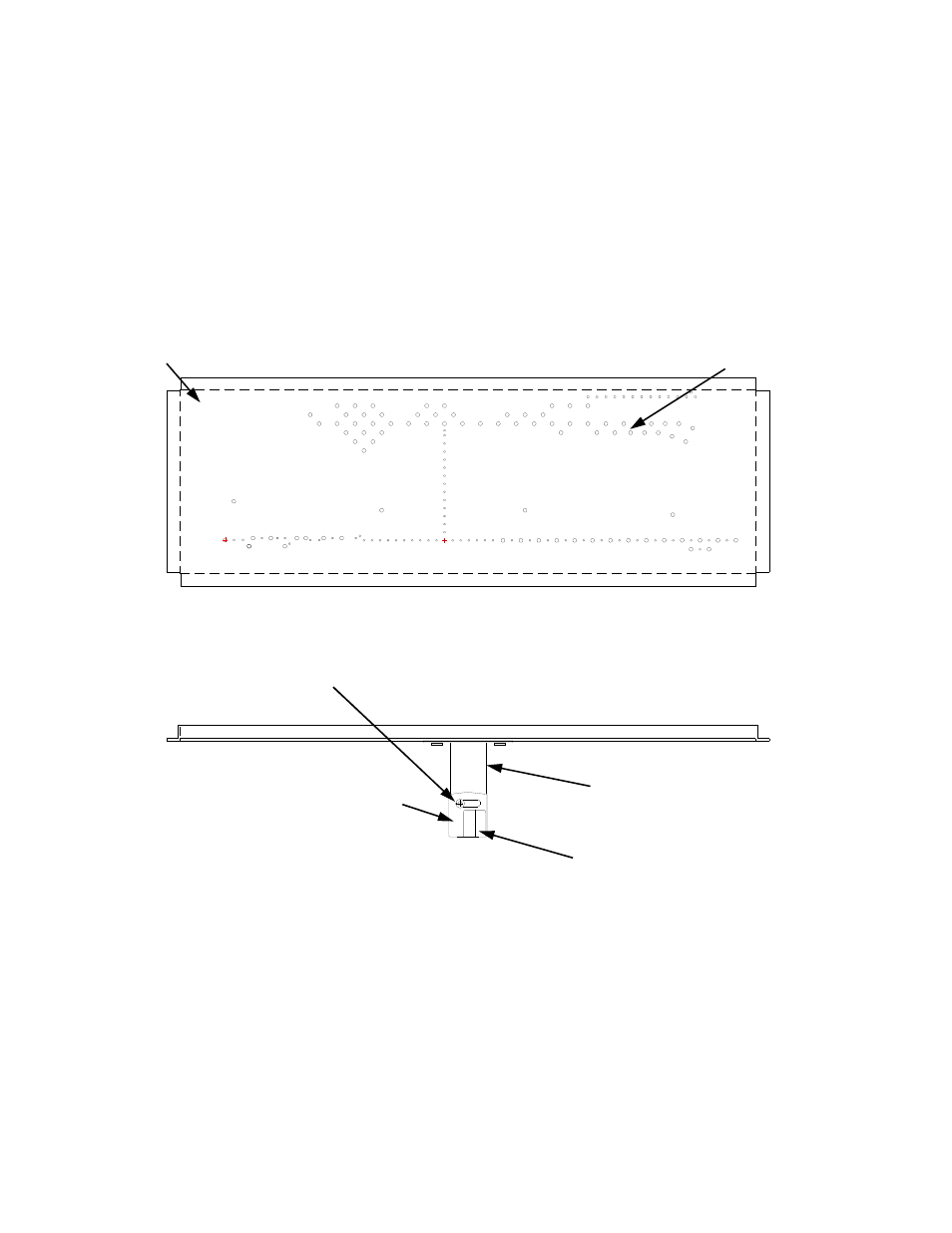

BURNER PAN ASSEMBLY

BURNER PAN

BURNER PORTS

AIR SHUTTER

(To Gain Access To The Air Shutter, Remove

The Cover Plate On The Orifice Box Located In

The Burner Control Compartment Directly Un-

der The Center Of The Burner Pan)

Philllips Head Screw

Air Shutter Slot (Opening)

VENTURA ASSEMBLY

LOGS:

•

If you remove logs for cleaning, refer to Installing Logs, page 18 to properly replace logs.

•

Use a vacuum cleaner to remove any carbon buildup on logs.

Replace logs if broken. See Replacement Parts on page 29.

• Also use a vacuum cleaner to remove any particles on the Burner Pan.

EMBERS:

“Apply loose material per instructions manual. DO NOT apply extra material or material not

supplied with the heater. Replace only with material from your Buck Stove dealer or from New

Buck Corporation.

Page 26