4) reliability test method, Mechanical – Mag Layers USA MSCDRI-2D09C User Manual

Page 3

(4) RELIABILITY TEST METHOD

MECHANICAL

TEST ITEM

SPECIFICATION

TEST DETAILS

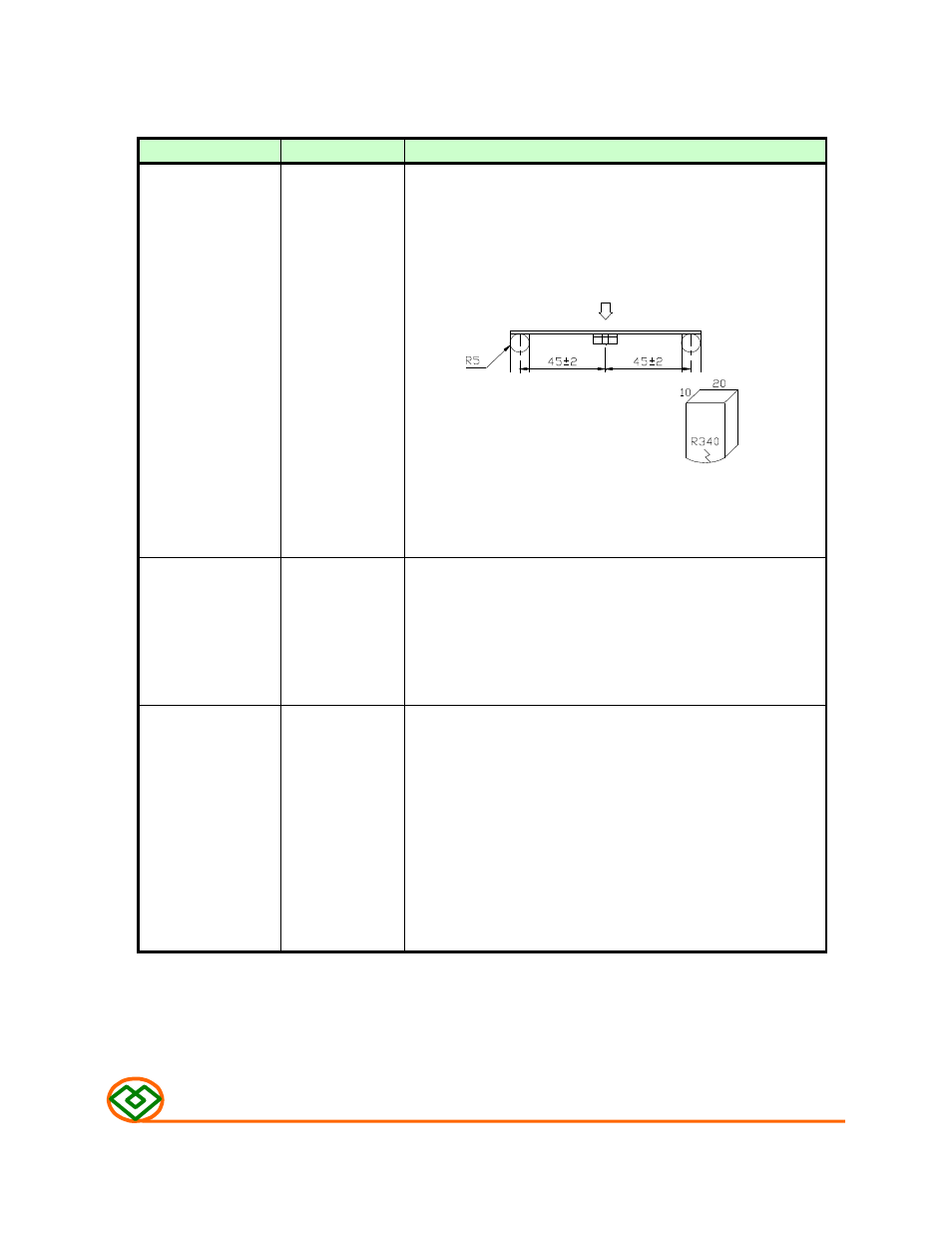

Substrate bending

△L/Lo≦

±5%

The sample shall be soldered onto the printed circuit board

in figure 1 and a load applied unitil the figure in the arrow

There shall be

direction is made approximately 3mm.(keep time 30 seconds)

no mechanical

PCB dimension shall the page 7/9

damage or elec-

F(Pressurization)

trical damege.

Vibration

△L/Lo≦

±5%

The sample shall be soldered onto the printed circuit board

and when a vibration having an amplitude of 1.52mm

There shall be

and a frequency of from 10 to 55Hz/1 minute repeated should

no mechanical

be applied to the 3 directions (X,Y,Z) for 2 hours each.

damage.

(A total of 6 hours)

Solderability

New solder

Flux (rosin, isopropyl alcohol{JIS-K-1522}) shall be coated

More than 90%

over the whole of the sample before hard, the sample shall

then be preheated for about 2 minutes in a temperature of

130~150℃ and after it has been immersed to a depth 0.5mm

below for 3

±0.2 seconds fully in molten solder M705 with

a temperature of 245

±5℃.

More than 90% of the electrode sections shall be couered

with new solder smoothly when the sample is taken out of

the solder bath.

Page-3/8

MSCDRI-2D09C-SERIES

PRESSURE ROD

figure-1

M A G .L A Y E R S