4) reliability test method, M ag .lay e r s, Mechanical – Mag Layers USA MCD-1618 User Manual

Page 3: Environmental, Page-3/4, Mcd-1618-series

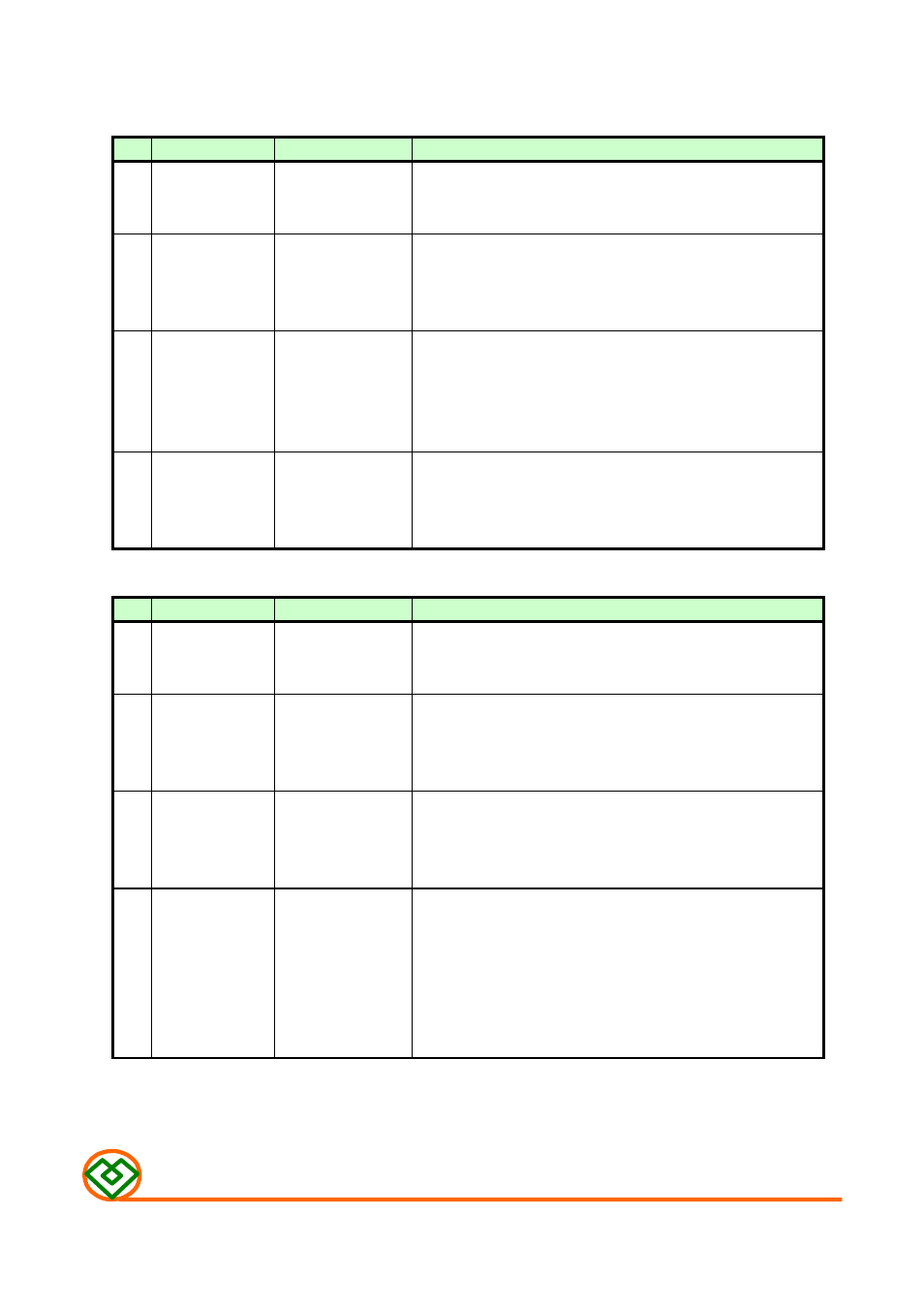

(4) RELIABILITY TEST METHOD

MECHANICAL

NO.

ITEMS

1

Solderability test

Dipping: 245

± 5 ℃, 3 ± 1 seconds

2

lead tensile

1.0 Kg MIN.

The lead of product is pulled with a load of

strength test

1.0kg mininum until lead breakdown. The tensile

force shall be recorded.

3

Vibration test

△L/L≦

±7%

The product is fixed ento the vibration with

Visual:OK

amplitude of 1.52m/m at a frequency of 10~55Hz

sweeping for lmin. The vibration is done at X,Y,

Z direction respectively for 2 houes, totally 6

hours.

4

Soldering heat

Visual:OK

The leads of product are dipped into a solder pot

resistance test

Circuit:OK

of 260

±5℃ for a duration of 10±1sec. Nothing

particular on visual and open circuitry as a

result of ore testing.

ENVIRONMENTAL

NO.

ITEMS

1

Humidity

△L/L≦

±5%

The product is placed in a chamber of 40

±2℃,

endurance

90~95%RH for 96 hours. Measurement is done

test

after the reaovery of 4~24 hours.

2

High temp

△L/L≦

±5%

The product is placed in a chamber of 80

±2℃,

endurance test

for 72 hours. Measurement is done after recovery

of 4~24 hours.

3

Low temp test

△L/L≦

±5%

The product is placed in a chamber of -40

±2℃,

for 96 hours. Measurement is done after

recovery of 4~24 hours.

4

Thermal shock

△L/L≦

±5%

The specimens are placed in a chamber and the

test

temp is then lowered to -20

±2℃ for one hour.

The temp will raised to +80

±2℃ for one hour.

This constitues one cycle. Ten cycles of such

testing shall be completed. Measurement is made

after recovery for 4~24 hours from the

completion of testing.

Page-3/4

SPECIFICATIONS

CONDITIONS

MCD-1618-SERIES

CONDITIONS

SPECIFICATIONS

More than 90% of the

termnial electrode

should be covered

with solder.

M AG .LAY E R S