Mag Layers USA GMLB-201209 User Manual

Page 8

MAG.LAYERS

GMLB-201209-R Series

R

R

R

E

E

E

L

L

L

I

I

I

A

A

A

B

B

B

I

I

I

L

L

L

T

T

T

Y

Y

Y

T

T

T

E

E

E

S

S

S

T

T

T

•

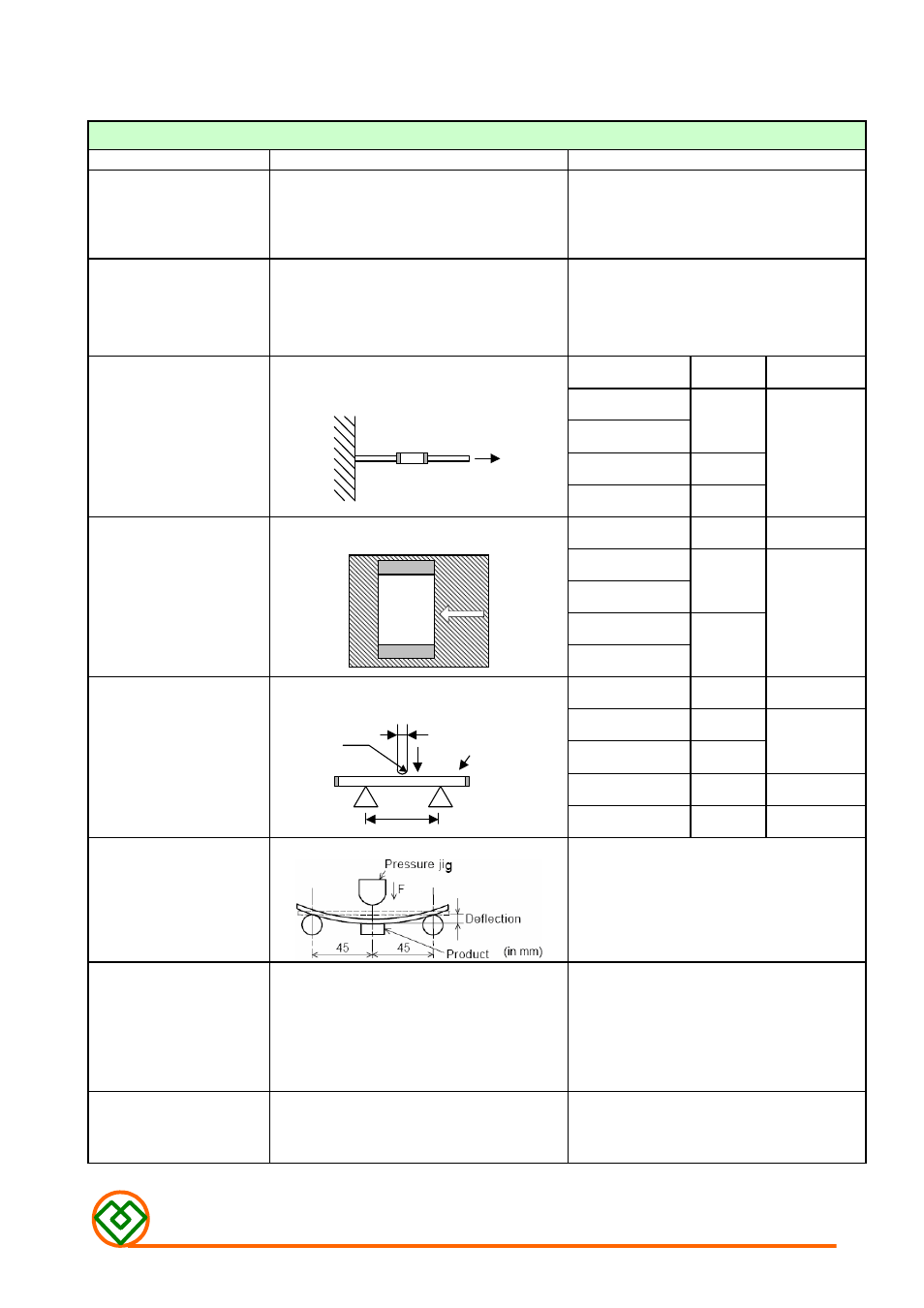

Mechanical Performance Test

ITEM

SPECIFICATION

TEST CONDITION

Solderability

More than 90% of the terminal electrode shall

be covered with fresh solder.

Solder: 96.5Sn-3.0Ag-0.5Cu

Solder Temperature: 245

±

5

℃

Flux: Rosin

Dip Time: 3

±

1 Seconds

Soldering Heat Resistance

The chip shall not crack.

More than 75% of the terminal electrode shall

be covered with solder.

Solder: 96.5Sn-3.0Ag-0.5Cu

Solder temperature : 260

±

5

℃

Flux: Rosin

Dip time: 10

±

1 seconds

TYPE

W(KGF)

TIME (SEC)

GMLB-160808

GMLB-201209

0.6

GMLB-321611

1.0

Terminal Strength

The terminal electrode shall not be broken off

nor the ferrite damaged.

W

GMLB-453215

1.5

30

±

5

TYPE

W(KGF)

TIME (SEC)

GMLB-160808

GMLB-201209

1.0

GMLB-321611

Terminal Strength

The terminal electrode shall not be broken off

nor the ferrite damaged.

GMLB-453215

2.0

10

±

5

TYPE

A(MM)

P(KGF)

GMLB-160808

1.0

GMLB-201209

1.4

1.0

GMLB-321611

2.0

2.0

Bending Strength

No mechanical damage.

The ferrite shall not be damaged.

A

Chip

P

1.0

R0.5

GMLB-453215

2.7

2.5

Bending Test

Appearance: No damage

Substrate: PCB(100mm

×

40mm

×

1.6mm)

Solder: Reflow

Speed of Applying Force: 0.5mm / s

Deflection: 2mm

Hold Duration: 30 s

Vibration

Impedance shall be within

±

20% of the initial

value.

There shall be no mechanical damage.

The sample shall be soldered onto the printed

circuit board and when a vibration having an

amplitude of 1.52mm and a frequency of from

10 to 55Hz/1 minute repeated should be

applied to the 3 directions (X,Y,Z) for 2 hours

each.

Drop shock

No apparent damage

Dropped onto printed circuit board from

100cm height three times in x, y, z directions.

The terminals shall be protected.

W