Loading aluminum wire – Longevity SpoolGun 140 User Manual

Page 14

SpoolGun 140 compatible with the MigWeld 140

14 |

P a g e

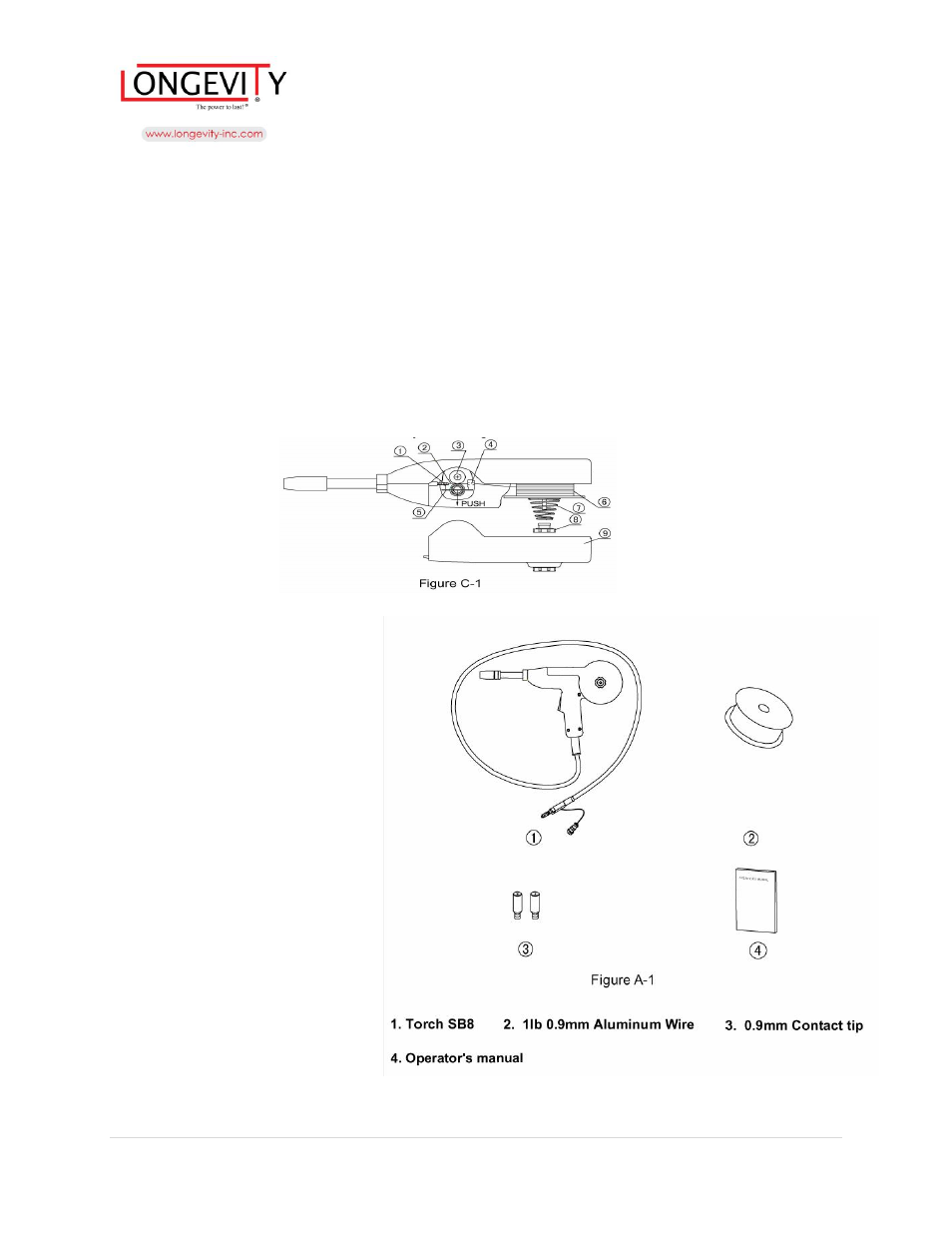

Loading Aluminum Wire

(see FigureC-1)

1. Remove left cover (9), nut (8) ,conical spring(7) in sequence. Load4" (100mm) wire (6) on the spindle,

(note: the direction Of the wire running is counterclockwise). Then install back all removed parts followed

by conical spring, nut, left cover.

2. Extend approximately 12 inches of wire (2) from spool. Straighten it out by back-bending it. Use care to

prevent the wire from unwinding.

3. Cut Off bent end of wire, leaving 100mm long straight section

4. Gently pull open the idle roll assembly to expose the drive roll grove. Guide straightened wire through inlet

wire guide (4) and toward drive roll groove (3).

While holding open the idle roll (5), slide end of wire through drive roll's groove and toward gun tube liner

(1).

5. Release the idle roll assembly and the straightened wire.

Welding Procedure

1 .Connect input power to the machine.

2, Screw off the nozzle and contact tip,

3~ Press the trigger, then the driver

feeds the wire into the gun, Release

the trigger when wire come out

from the mouth of the gun,

4. Screw on the contact tip and nozzle.

5. Cut off the aluminum wire so that it

extends about 1/4 inches (6-10mm)

from the contact tip.

When welding

1. Select suitable wire and gas

according to the type and thickness of

the work piece refer to related Welding

Manual.

2. According to the wire and thickness

of the work piece set wire speed and

Unpacking

When unpacking, check to make sure

the following parts are include

(See Figure A-l)