Longevity STICKWELD 140 User Manual

Page 22

21 |

P a g e

LONGEVITY® Global, Inc. thanks you for your purchase and the opportunity to be able to serve you. If,

after reviewing this manual, you have any problems in setting up or operating your machine, contact us

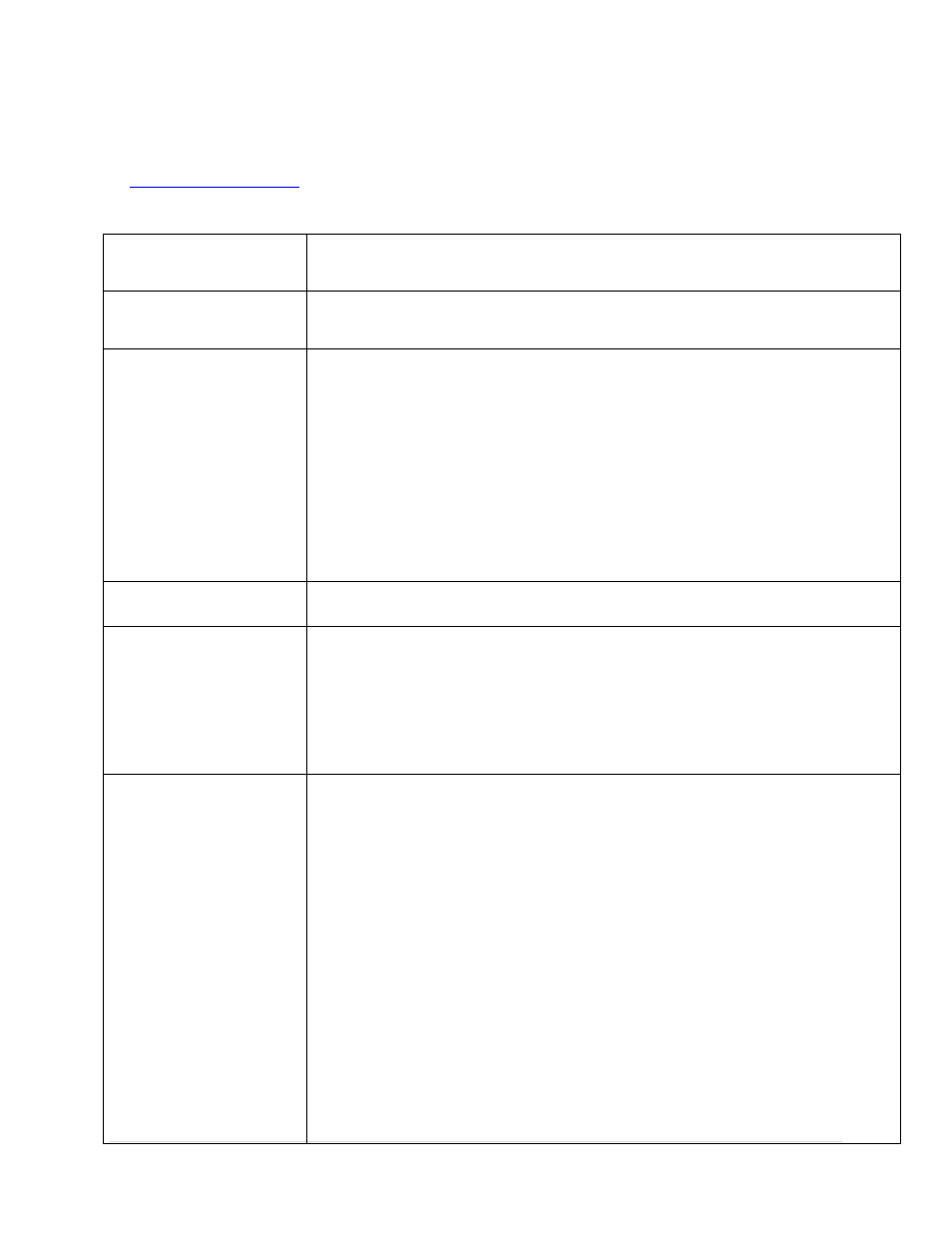

Faults symptom

Solutions

Power indicator is not lit,

fan is not working, no

welding output.

A. Make sure power switch is connected properly.

B. Make sure your power plug is connector to the proper voltage.

Power indicator is lit, fan

doesn

’t work, no welding

output.

A. Check the input power to make sure you are connected to the proper

power level

– either 110v or 220v

B. Dirty or Unstable power is detected and the machine has entered a fail

safe mode. Unplug and restart the machines after 5 minutes once the

voltage is stable.

C. Restart the machine but unplugging the power cable and turning the

machine on in 5 minutes

D. Cables in the power plug or the machine power switch are loose or not

connected firmly.

ARC Welding Current

Knobs is Erratic

A. Amp Adjustment Knobs needs replacement along with potentiometer.

B. Terminal of output has a broken circuit or poor connection.

Fan is working and

abnormal indicator is not

lit, no welding output.

A. Check if components are connected properly.

B. Check if the output terminals are connected properly.

C. If there are questions about the mother board, contact the authorized repair

center.

Fan is working and

abnormal indicator is lit,

no welding output.

A. Overload current protection may start, please turn off machine first, then

restart it after abnormal indicator is off.

B. Overheat protection may start, it will become normal in 2-3min.

C. Inverter circuit may go wrong. Please disconnect the power supply plug of

the main transformer on MOS board (near fan VH-07), then restart the

machine.

1) If abnormal indicator is still lit, that means some fieldistors on MOS

board are damaged. check and replace them.

2) If abnormal indicator is off:

a. Maybe transformer of middle board is damaged, measure primary

inductance value and Q value of main transformer by inductance

bridge.

b. Primary value is parallel circuit, L=1.2-2.0mH, Q>40 If inductance

value and Q value is low, replace it.

c. Maybe some of secondary rectifier tube of transformer is broken,

check and replace rectifier tube.

D. Maybe feedback circuit is in fault.

Power supply

(1phase ~ 220V)

Electrode holder

Earth clamp