Longevity STICKWELD 140 User Manual

Page 14

13 |

P a g e

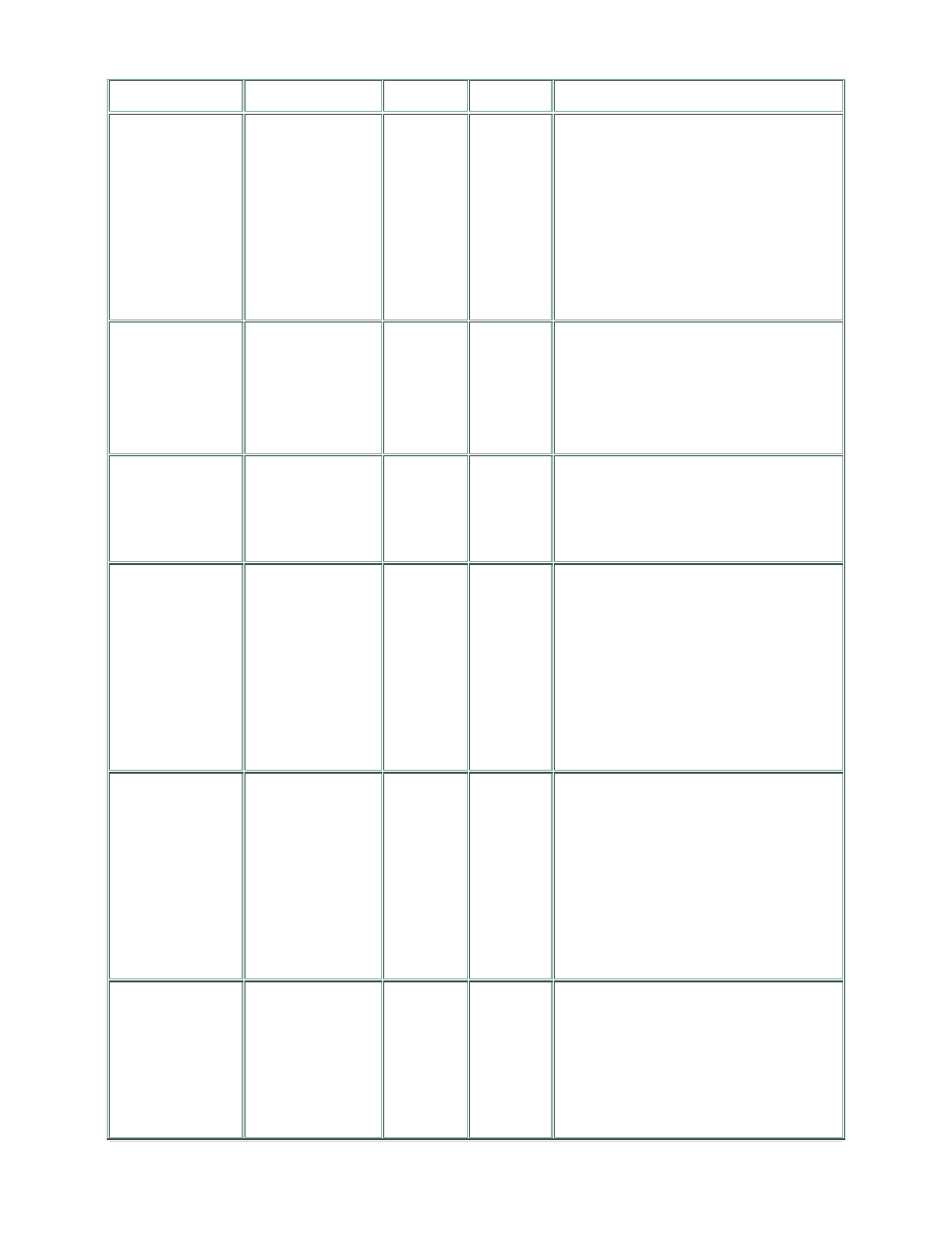

than E6010/E6011.

E6013

High-titania

potassium

F, V,

O, H

ac,

dcen,

dcep

Similar to E6012; quieter arc,

smoother bead, cleaner weld

metal, fewer inclusions

Characteristics vary with

supplier. Run at lower current

than for E6012.

E6022

High iron

oxide

F

ac,

dcep,

dcen

Use for single-pass,

high-current, high-speed

welding of groove welds in flat

position horizontal lap joints

and fillet welds in sheet metal.

E6027

High iron

oxide,

iron powder

H-fillets,

F

ac, dcep

For fillet of groove welds, flat

position, heavy slag, good

sidewall fusion. Use at high

amperages on thick plate.

E7014

Iron powder,

titania

F, V,

O, H

ac, dcep

Iron powder boosts deposition

rate and efficiency. Use at high

amperages on carbon and

low-alloy steels.

Low-penetrating arc, use to

bridge poor fitups. Smooth,

fine-rippled bead, convex

fillets.

E7018,

7018-1

7018R

7018-1R

7018H16, H8,

H4

Low-hydrogen

potassium,

iron powder

F, V,

O, H

ac, dcep

Iron-powder addition increases

deposition rate. Use on carbon,

high-carbon, and low-alloy

steels. Smooth arc, low spatter.

Flat and horizontal welds are

finely rippled. Convex. Other

types: E7018-1H16R,

E7018-1H8R, E7018-1H4R.

E7018M

Low-hydrogen

iron powder

F, V,

O, H

dcep

Yield strength, 53,000-72,000

lb/in. Ductility high, extra

impact strength and

compositional limits and limits

on moisture and hydrogen.

Similar to E7018-1H4R,