JULABO FLW4006 Recirculating Coolers User Manual

Page 14

14

3.1. Cooling

water

connection

Only for water cooled models - FLW:

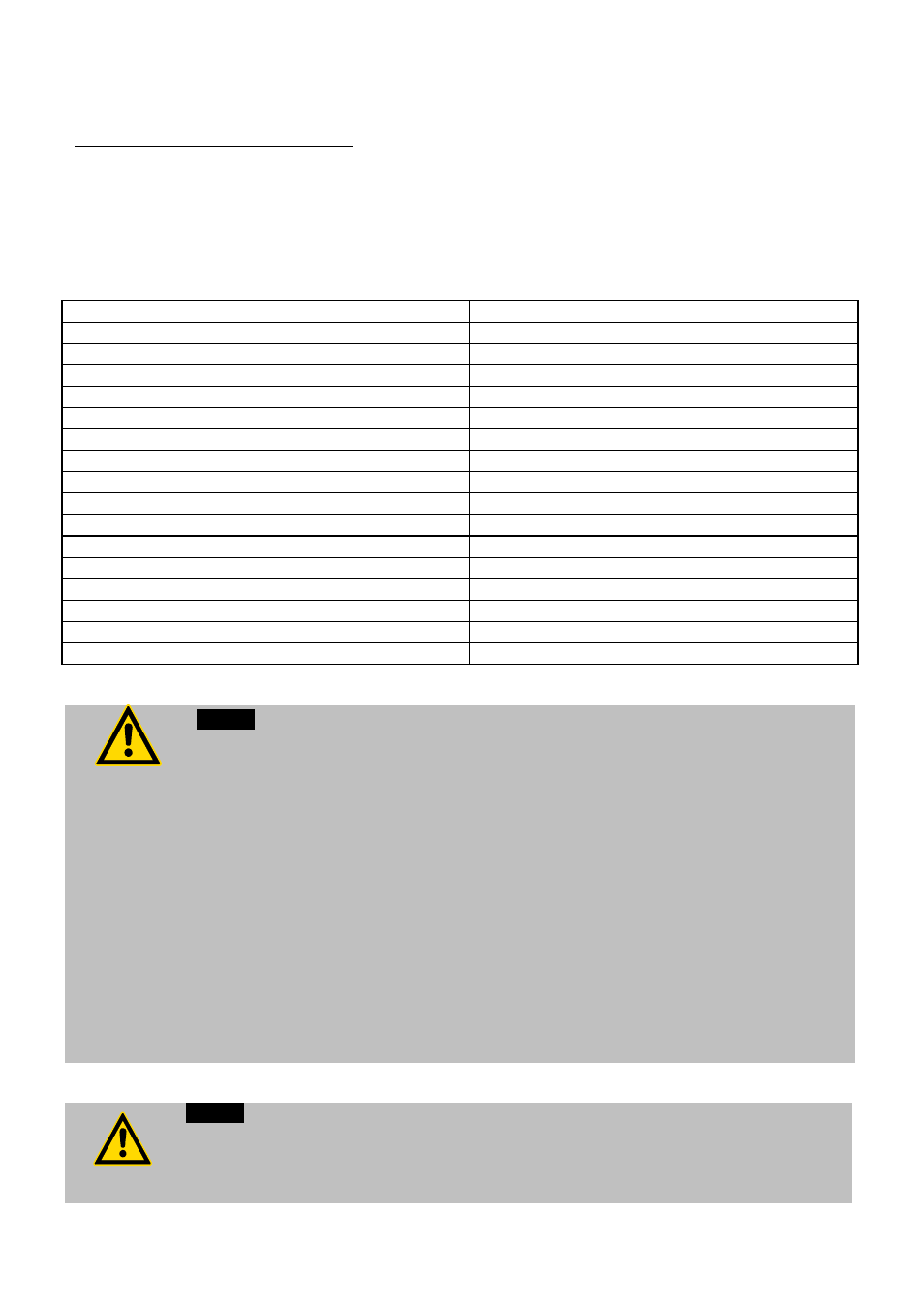

Cooling water pressure (IN / OUT )

max.

6 bar

Difference pressure (IN - OUT )

2 … 6 bar

Flow rate on FLW250x

typical

4,1 l/min

Flow rate on FLW400x

typical

6,6 l/min

Cooling water temperature

<20 °C

Recommended quality of cooling water:

pH – value

7,5 to 9,0

Sulfate [SO4 2- ]

< 100 ppm

Hydrocarbonate [HCO3- ] / Sulphate [SO4 2-]

> 1 ppm

Hardness [Ca2+, Mg2+] / [HCO3-]

> 0,5 dH

Alkalinity

60 ppm < [HCO3-] < 300 ppm

Conductivity

< 500 μs / cm

Chloride (CL-)

< 50 ppm

Phosphate (PO43-)

< 2 ppm

Ammonia (NH3)

< 0,5 ppm

Free Chlorine

< 0,5 ppm

Ferri Ions (Fe3+ )

< 0,5 ppm

Mangano Ions (Mn2+)

< 0,05 ppm

Carbon dioxide (CO2)

< 10 ppm

Hydrosulfide (H2S)

< 50 ppm

Content of oxygen

< 0,1 ppm

Algae growth

impermissible

Suspended solids

impermissible

Notice:

Danger of corrosion of heat exchanger due to unsuitable quality of cooling

water.

Due to its high content of lime hart water is not suitable for cooling and causes

calcination of the heat exchanger.

Ferrous water or water containing ferrous particles will cause formation of rust

even in heat exchangers made of stainless steel.

Chlorous water will cause pitting corrosion in heat exchangers made of stainless

steel.

Due to its corrosive characteristics distilled and deionized water is unsuitable and

will cause corrosion of the bath. .

Due to its corrosive characteristics sea water is not suitable.

Due to its microbiological (bacteria) components which settle in the heat

exchanger untreated and unpurified river water and water from cooling towers is

unsuitable.

Avoid particulate matter in cooling water.

Avoid putrid water.

Notice:

Cooling water circuit

Risk of oil leaking from the cooling circuit (compressor) of the recirculating cooler into

the cooling water in case of a fault in the circuit!

Observe the laws and regulations of the water distribution company valid in the location

where the unit is operated.