Surface mount dip switches – Grayhill DIP Switches: Surface Mount 90HB Series User Manual

Page 2

Series

Terminal Style: W = Gull Wing, J = J-Bend

RoHS compliant

90HBW02PRT

Packaging: R = Tape and reel packaging (750 switches/reel)

Blank = Tube packaging (each tube is 19.5" long)

Seal: P = Polyimide Seal

Blank = No Seal

Number of Positions: 02 through 10

Surface Mount DIP Switches

Meets requirements of

EIA 481-2 or EIA 481-3

Each reel has a 15.750 inch (390 mm)

minimum leader and a 6.30 inch (160 mm)

minimum trailer.

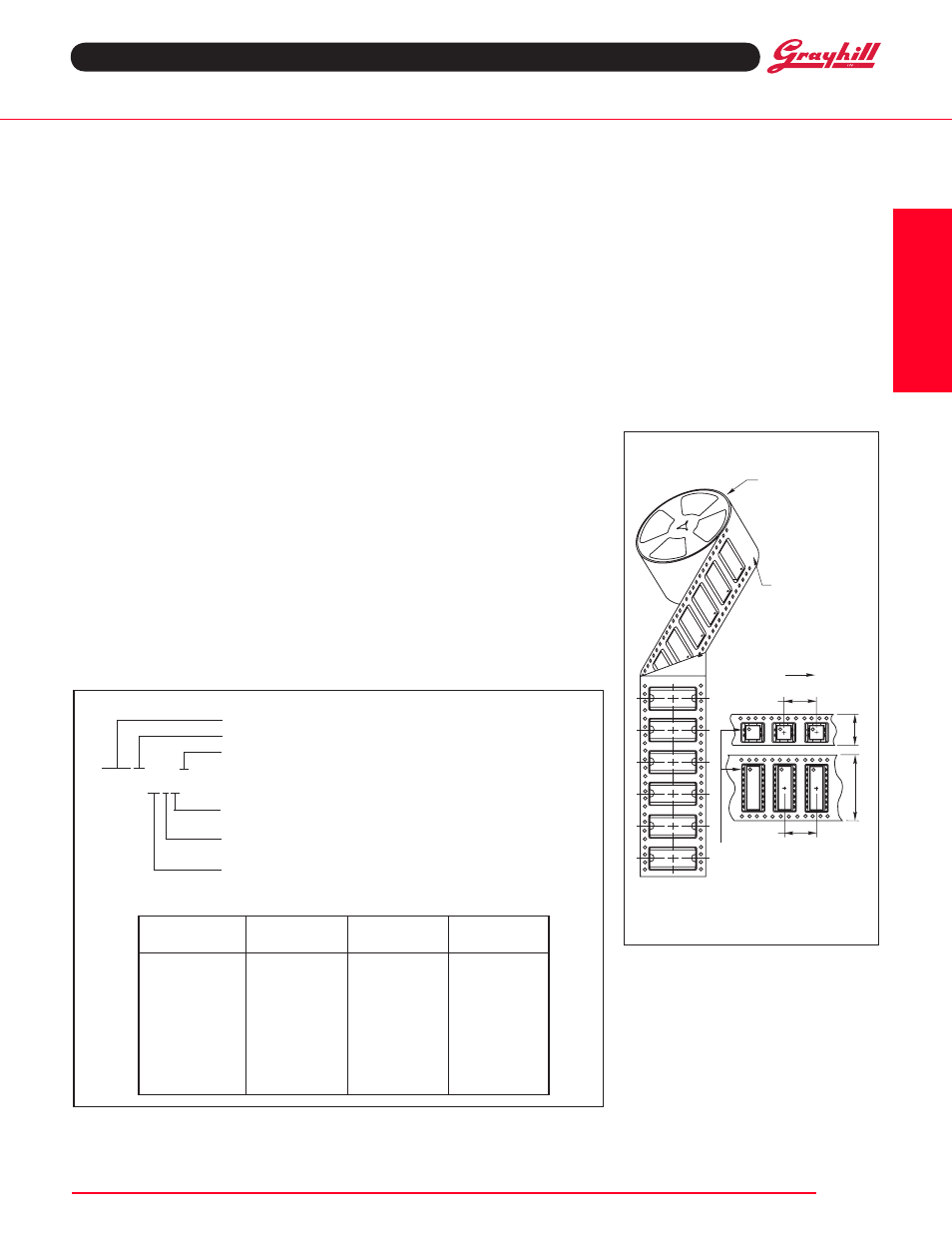

TAPE AND REEL PACkAGING

13 INCH

DIAMETER REEL

DIRECTION

OF FEED

24mm

TAPE

16mm

32 &

44mm

TAPE

16mm

PIN ONE LOCATION

CONDUCTIVE

PLASTIC EMBOSSED

TAPE

SpecificationS

electrical Ratings

Make-and-break current Rating: 2,000

operations per switch position at these resistive

loads:10 mA, 30 Vdc; or 10 mA, 50 mVdc; 10 mA,

50 mVdc; or 25 mA, 24 Vdc; or 100 mA,6 Vdc.

contact Resistance: (measured at 10 mA, 50

mVdc). Initial: 20 mohms maximum, After Life:

100 mohms maximum

insulation Resistance: Minimum, at 100 Vdc

between adjacent closed contacts and also

across open switch contacts.

initial (Mohms): 5,000, After Life (Mohms):

1,000

Dielectric Strength: Minimum voltage (AC

RMS) measured between adjacent closed

contacts and also across open switch

contacts.

lnitial: 500 volts, After Life: 500 volts

current carry Rating: 3A maximum rise of

20°C

Switch capacitance: 2 pF at 1 megahertz

Mechanical Ratings

Where Grayhill performance is superior, the MIL

spec is listed in parentheses.

Mechanical Life: 2,000 operations per switch

position

Vibration Resistance: Per Method 204, Test

Condition B , 1mS opening (10 mS allowed)

Mechanical Shock: Per Method 213, Test

Condition A. 1mS opening (10 mS allowed)

thermal Shock Resistance: Per specification;

no failures; passes contact resistance.

terminal Strength: Per specification

thermal aging: 1,000 hours at 85°C; no

failures.

environmental Ratings

Meets all requirements of MIL- S-83504**.

operating temperature Range: -40°C to +

85°C

Storage temperature Range: -40°C to +

85°C

Moisture Resistance: Per MIL-STD-202,

Method 106.

Soldering information

Solderability: Per MIL-STD-202, Method 208

Soldering Heat Resistance: Per MIL-S-83504,

six second test.

Recommended processing temperature:

220°C–230°C (1 pass—260°C maximum)

processing position: Switch is to be processed

with all actuators in the closed (on) position as

shipped.

fluxing: Per EIA RS-448-2 with flux touching

switch body.

cleaning: Passes immersion test using water/

detergent. Acceptable solutions include 1-1-1

trichlorethane, freon, (TF, TE, or TMS), isopropyl

alcohol, detergent (140°F maximum). Terpene

acceptable for Series 90 only. Solutions which are

not recommended include acetone, methylene

chloride, freon TMC. High pressure aqueous

cleaning is not recommended.

Materials and finishes

Shorting Member (Ball): Brass, gold-plate

over nickel barrier.

Base contacts: Copper alloy, gold-plate

over nickel barrier.

terminals: Copper alloy, matte tin plated over

nickel barrier.

non-conductive parts: Thermoplastic

(uL94V-O)

tape and Reel packaging

tape Seal integrity: Passes gross leak test

using 125°C flourinert for 20 seconds minimum.

Reference MIL-STD-202, Method 112

tape Seal: Polyimide film

oRDeRing infoRMation

Available from your local Grayhill Distributor. For prices and discounts, contact a local Sales Office,

an authorized local Distributor or Grayhill.

** Note: 100% matte tin terminal plating does not meet MIL-S-83504 for lead content.

No. of

Length

Length

Number

Positions

Inches

Metric

Per Tube

2

.270"

6,9 mm

60

3

.370"

9,4 mm

47

4

.470"

11,9 mm

37

5

.570"

14,5 mm

31

6

.670"

17,0 mm

26

7

.770"

19,6 mm

23

8

.870"

22,1 mm

20

9

.970"

24,6 mm

18

10

1.070"

27,2 mm

16

DiP

6

DIP

Switches

Grayhill, Inc. • 561 Hillgrove Avenue • LaGrange, Illinois 60525-5997 • uSA • Phone: 708-354-1040 • Fax: 708-354-2820 • www.grayhill.com