Maintenance and inspection, Shutdown procedures, Starting – Gast ROA Series Laboratory User Manual

Page 3: Filter inspection and replacement

ƽ

WARNING The head surface(s) can be very hot

depending on pump duty and speed.

Do not touch these parts during

operation.

ƽ

CAUTION Do not operate these units above

25 in. Hg vacuum or 100 PSIG

pressure (45 PSIG intermittent). To

do so will damage the unit.

ƽ

WARNING Do not operate without the grille(s), if

provided, in place. Failure to do so

could result in severe personal injury.

Starting

ƽ CAUTION

Do not start against a vacuum or

pressure load.

If the pump is extremely cold, let it warm up to room

temperature before starting. If the pump does not operate

properly, see the troubleshooting guide.

NOTE: Some of these models may exceed

70 dB(A). When in close proximity to these models

hearing protection is required. Refer to the Techni

cal Data Sheet for your specific model.

MAINTENANCE AND INSPECTION

Intake filter and mufflers require periodic inspection and

replacement. Initial inspection is suggested at 500 hours,

then the user should determine the frequency thereafter.

Most problems can be prevented by keeping filters and

mufflers clean. Dirty filters and mufflers decrease pump

performance and can decrease pump life.

Filter Inspection and Replacement

The head surface(s) on some models can be very hot

during operation. Do not touch these parts until the

pump has been turned off and allowed to cool. Some

filter element(s) are held together by a snap fit. Remove

the cover to replace the felt, and reassemble.

SHUTDOWN PROCEDURES

Proper shutdown procedures must be followed to prevent

pump damage. Failure to do so may result in premature

pump failure. The Gast Manufacturing non-lubricated

vacuum pumps and compressors are constructed of

ferrous metals or aluminum which are subject to rust and

corrosion when pumping condensable vapors such as

water. Follow the steps below to assure correct storage

and shutdown between use:

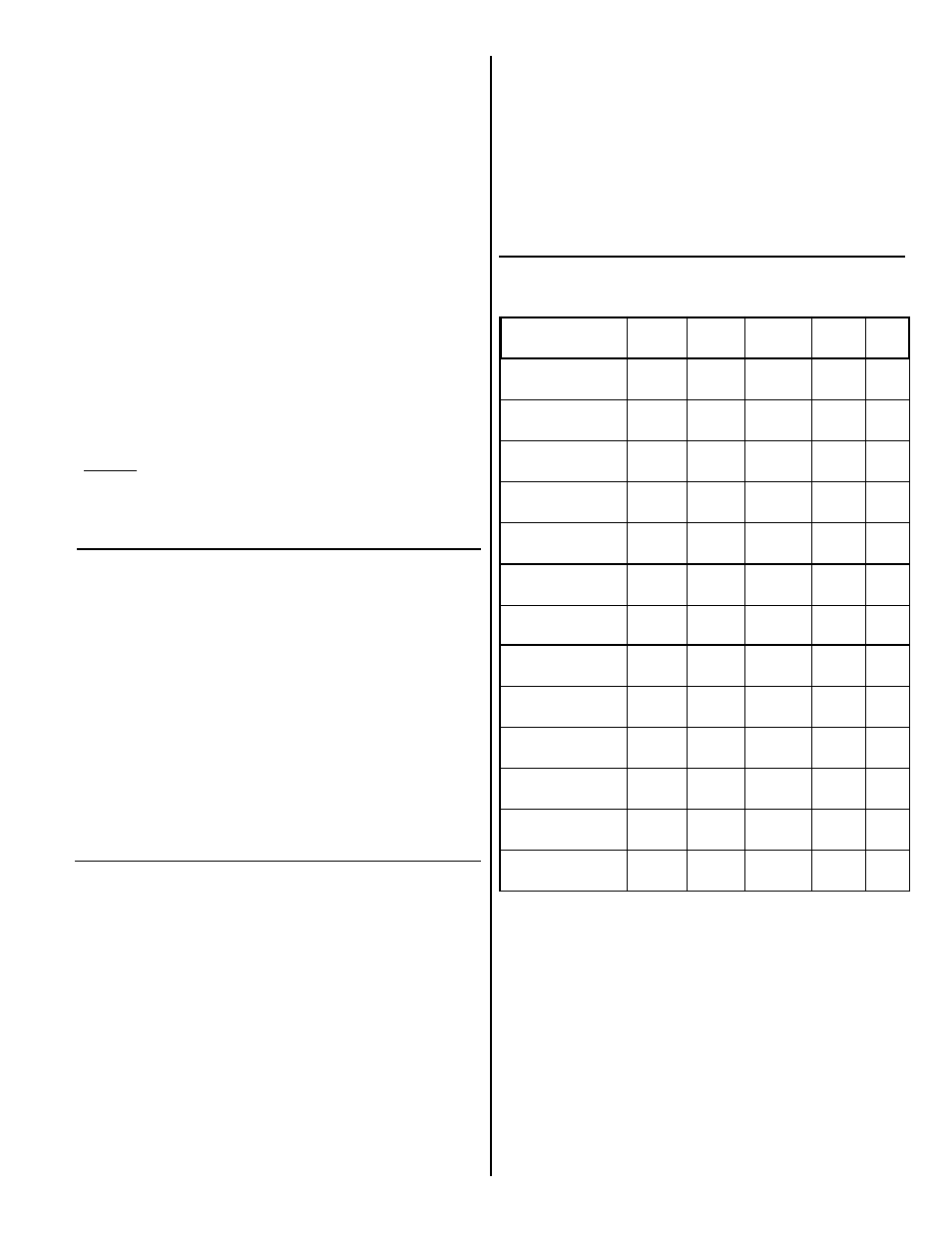

Possible Reason

Low

Pressure

Low

Vacuum

Excessive

Noise

Over-

heating

Won't

Start

Dirty Filter

X

X

Dirty Muffler

X

X

Dirty Valves

X

X

Bent Valves

X

X

Damaged Cup

X

X

Low Voltage

X

X

X

X

Wrong voltage

X

X

X

Pressure on Head

X

Improper Cylinder

Shimming

X

X

Relief Valve Set

Too High

X

Relief Valve Set

Too Low

X

X

Leaky Hose

X

X

Leaky Check

Valve

X

Shutdown Procedure Conti.

1. NEVER oil this non-lubricated pump.

2. After using the pump, disconnect plumbing and allow

the pump to run "open" for at least 5 minutes before

shutdown.

3. Plug the open ports to prevent dirt or other

contaminents from entering the pump. It is now ready

for shutdown or storage.

TROUBLESHOOTING GUIDE

Service Kit(s) and repair instructions are available

upon request. Contact your local Represetative,

Distributor, or the factory for details.

NOTE: Gast will not guarantee the performance of

a field rebuilt pump. You can return the pump to an

Authorized Service Facility listed on the back page.