Best practices – Flex RhinoBond Project User Manual

Page 4

Best

Practices

RP12222

Rev

. 0812

RhinoBond

®

is a trademark of OMG, Inc. Copyright © 2012 OMG, Inc. Used with permission.

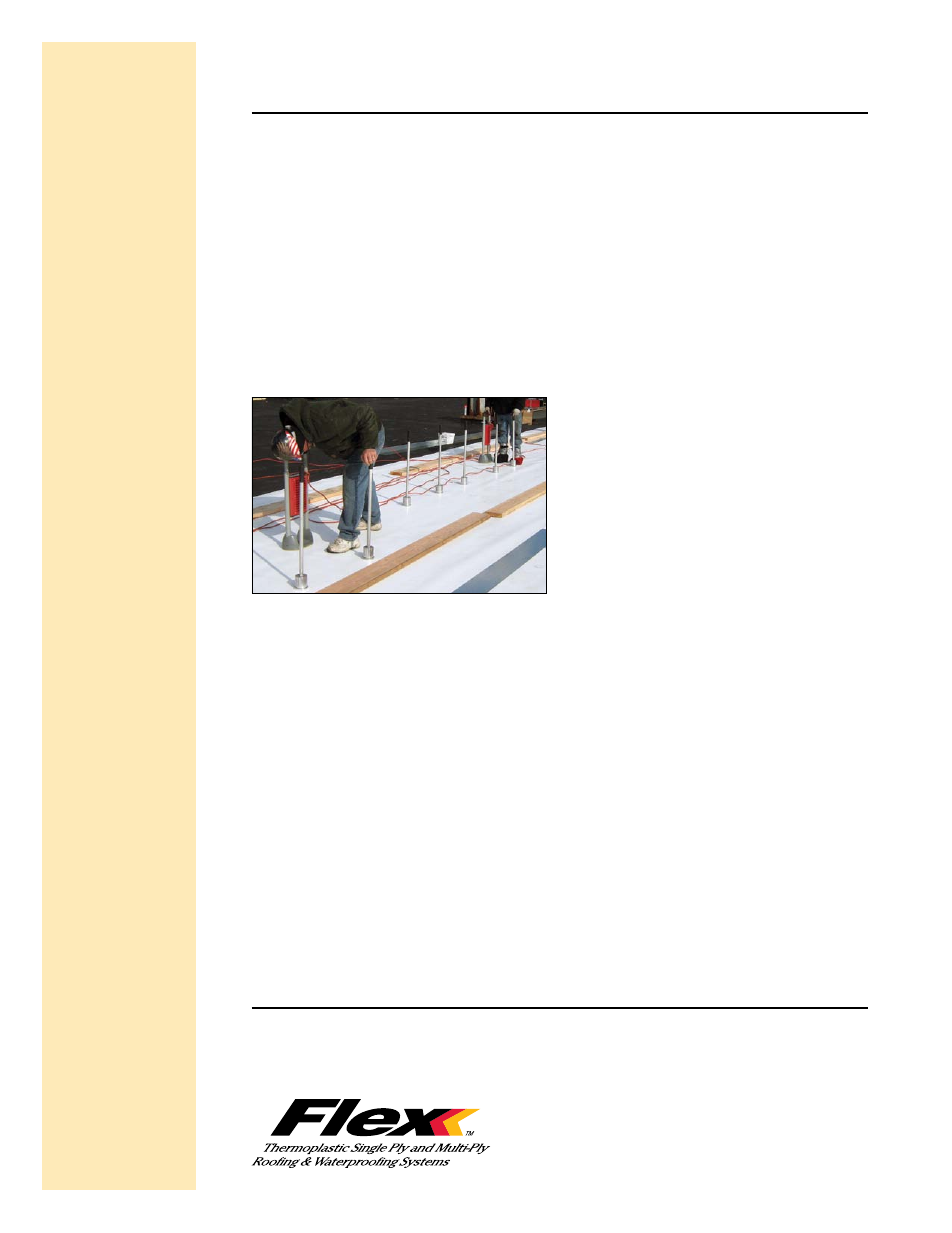

weld in sTraighT lines

Operator #1 lines all of the magnets up on the first

row. Operator #2 begins work on the adjacent row

after the first operator completes the first five welds.

This procedure helps make sure that the magnets

remain on the plates for at least one minute. This

method also minimizes motion and increases

productivity.

Magnets from the first row are used by the second

operator in the adjacent row. This procedure continues

across the roof.

Work one row after another for maximum productivity

Flex rhinOBOnd sTanding

seam reTrOFiT PrOJecTs

Night before:

Meet with foreman to discuss tool operation and

project coordination. This is KEY!

Day of:

•

Load roof

•

Fill flutes

•

Apply cover board

•

Snap lines over purlins

•

Apply fasteners and Flex RhinoBond plates

•

Blow any debris off cover boards and plates

with a leaf blower

•

Roll out membrane (position sheets so seams

do not fall on rows of plates)

•

Let sheets “relax”

•

Set seam welders for conditions and weld

membrane seams

•

Make sure generator is up to full speed and

delivering stable power before plugging in Flex

RhinoBond tool

•

Calibrate Flex RhinoBond tools and start bonding

plates

•

Ballast any sections that don’t get welded

Subsequent days:

•

2 guys with Flex RhinoBond tools finish welding

membrane from the previous day

•

All other guys in crew repeat the process above.

resOurces

Review Flex RhinoBond Owner’s Manual for additional

information.

How to Run a Flex RhinoBond Job • Page 4

cOnTacT

If you have any questions or need more information, contact the

Flex Technical or Sales Department at

1-800-969-0108.

Flex Membrane International Corp.

2670 Leiscz’s Bridge Road, Suite 400

Leesport, PA 19533 800-969-0108

www.flexroofingsystems.com