Flex RhinoBond Project User Manual

Best practices, How to run a flex rhinobond

Best

Practices

REVISED AUGUST 2012

How to Run a Flex RhinoBond Job • Page 1

Think OuTside The seams

With the Flex RhinoBond system, you

have to think differently when it comes to

scheduling and running your job, par-

ticularly when compared to a traditional

mechanically attached installation.

These Best Practice recommendations

are based on several years of Flex

RhinoBond project observation and

evaluation.

It should also be noted that for

improved productivity, a minimum of

two Flex RhinoBond tools should be

used.

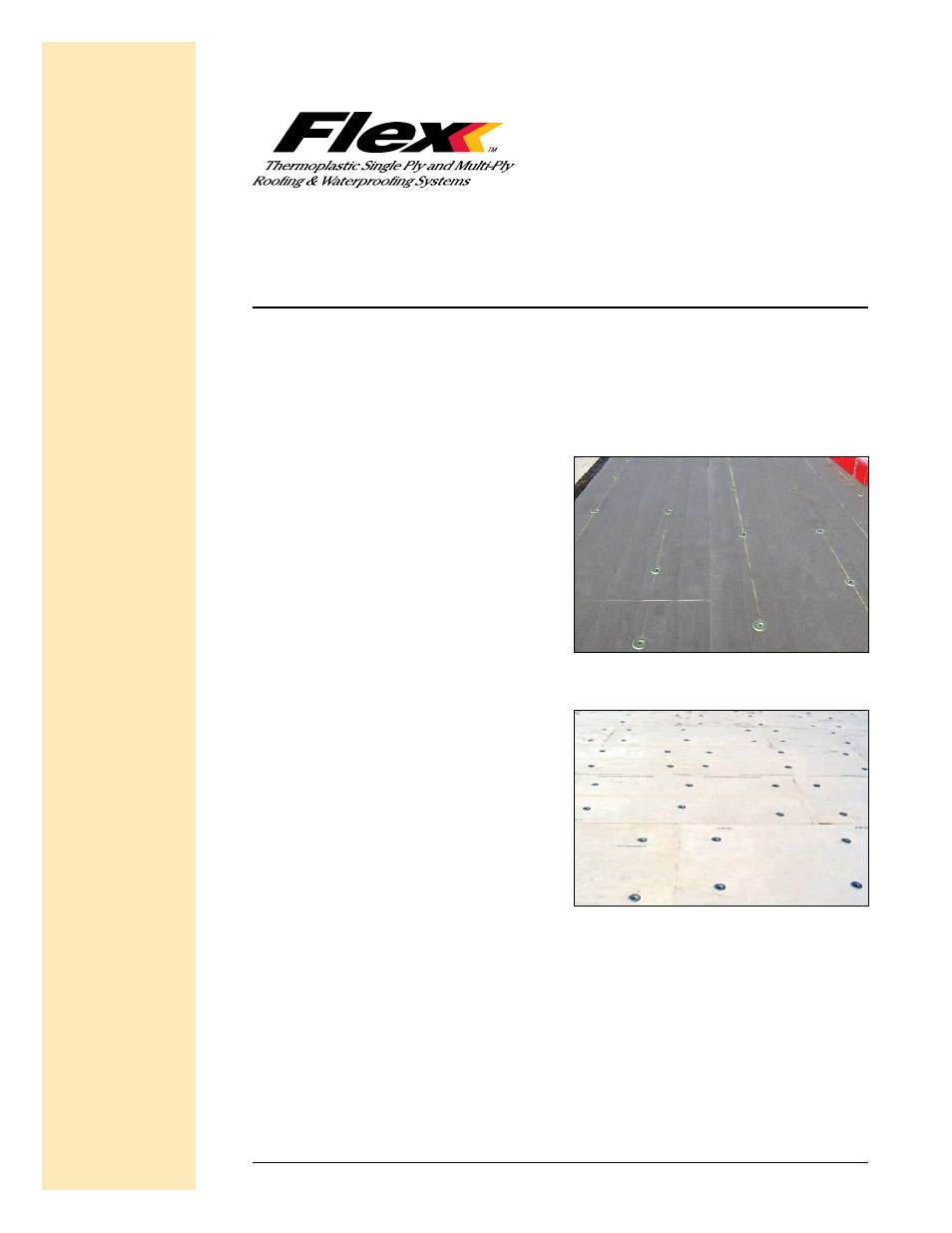

FasTener insTallaTiOn

Fasteners MUST be in a straight row in at least

one direction. The more even the spacing, the easier

they are to find under the membrane, and the faster

the installation.

Straight – good

Random – harder to find

Snap chalk lies to layout grid pattern for corners,

perimeter and field. Build an 8' template bar with grid

measurements marked on it to speed up marking for

chalk lines.

how to run a Flex rhinoBond

®

Job