Best practices – Flex RhinoBond Project User Manual

Page 2

How to Run a Flex RhinoBond Job • Page 2

Best

Practices

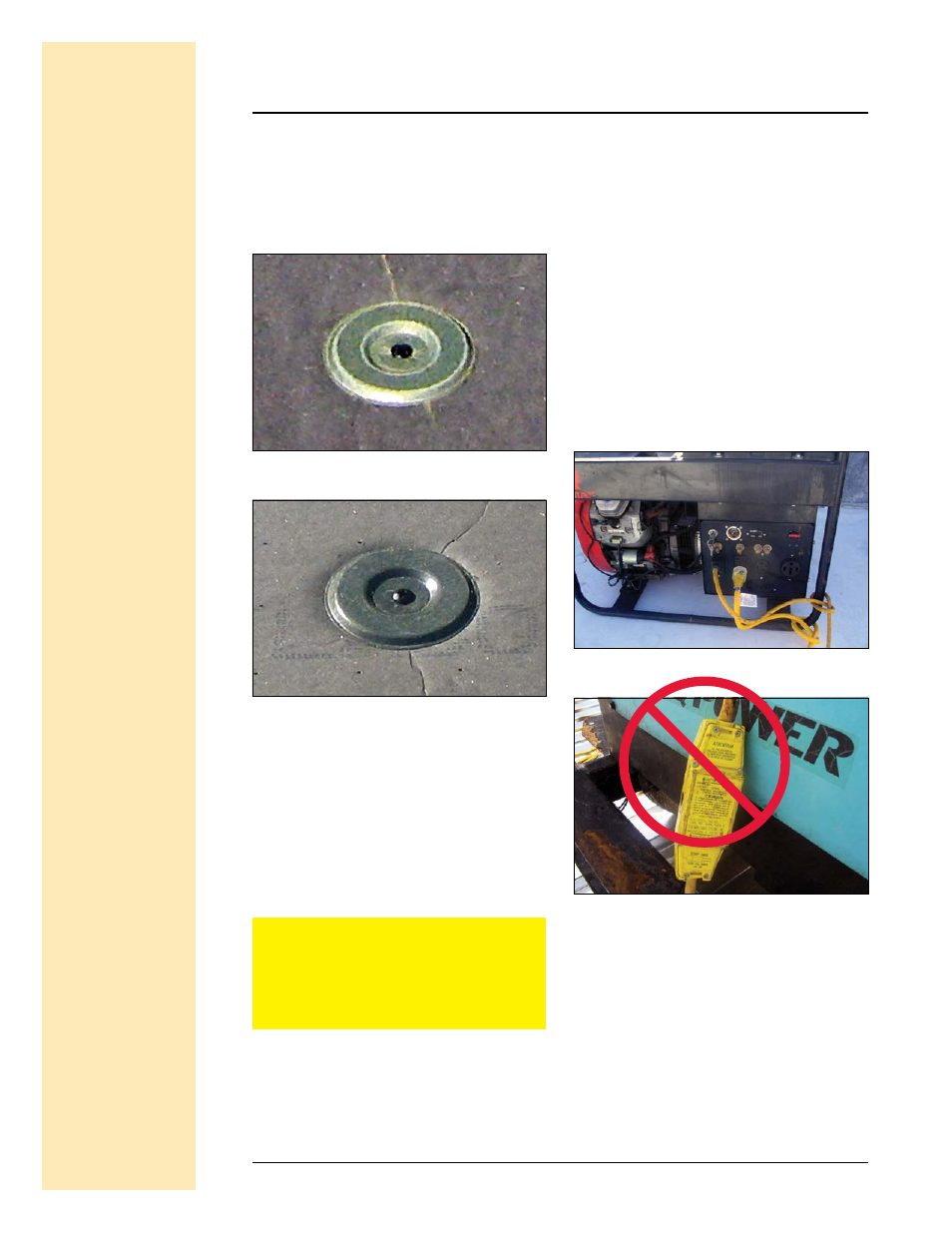

Fasteners must not be overdriven. They should be

tight enough that you can not turn the plates with your

hand. Overdriven fasteners are harder to find, and may

result in a poor or partial bond.

Proper installation

Overdriven

Position membrane so seams do not pass

directly over Flex RhinoBond plates. It is best to

install the membrane so that the seams are between

the rows of Flex RhinoBond plates. If a seam does

pass directly over a plate, weld the seam and then

bond the membrane to the Flex RhinoBond plate.

POwer requiremenTs

WARNING: Do not plug Flex RhinoBond tool

into generator until the generator is running

at full speed and delivering stable power.

Unstable power during start-up increases the risk

of damage to the Flex RhinoBond tool.

Each Flex RhinoBond tool should run on a dedicated

20A circuit, with no more than 100 feet of good quality

(12 ga. min.) extension cord per tool. Do not plug the

tools into a pigtail, and do not plug them into a 15A

GFCI adapter. Generator power usually works better

than house power because house power often requires

longer extension cords. The tools are designed to run on

105-130V. If the cycle time lasts more than 8 seconds,

check the power source.

Generators should be 5,000 watt (min.) with one 20A

GFCI circuit per tool. Two tools (max.) per 5,000 watt

generator.

NO OTHER TOOLS SHOULD BE PLUGGED

INTO DEDICATED FLEX RHINOBOND TOOL

GENERATOR DURING OPERATION.

One cord per circuit and per tool

Do not use pigtails

Static interference. If there is a radio on the job

site, you may hear interference (i.e. static) when the

tool is operating. Don’t worry, this is normal. The tool

meets FCC transmission requirements for industrial

tools, but can cause static interference under certain