Safety expansion contact block esm-es3, User information – EUCHNER ESM-ES3xx User Manual

Page 2

2

User Information

EUCHNER GmbH + Co. KG Kohlhammerstraße 16 D-70771 Leinfelden-Echterdingen Tel. +49/711/75 97-0 Fax +49/711/75 33 16 www.euchner.de [email protected]

Safety Expansion Contact Block ESM-ES3..

Note: The items listed under “Electrical connection” must be observed during commissioning.

Commissioning

Procedure

1. Wiring ESM-ES3.. :

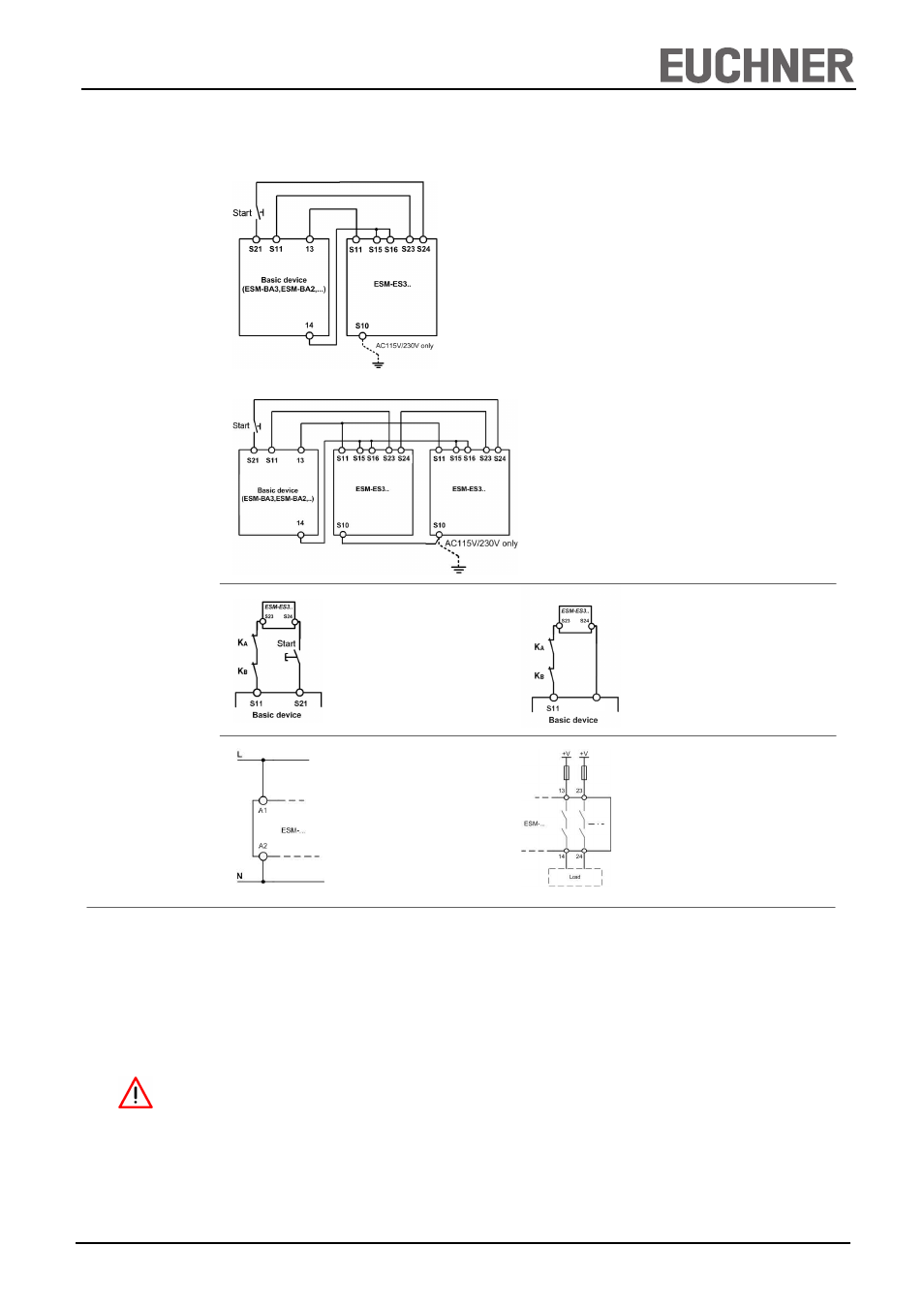

Wire the ESM-ES3.. with the EUCHNER basic device

according to your application (see Fig. 1 to Fig. 2).

2. Wiring basic device:

Wire the basic device according to the required Perform-

ance Level determined (see user information for the basic

device).

3. Wiring feedback loop:

Wire the feedback loop as shown in Fig. 3 and Fig. 4.

4. Wiring power supply:

Connect the power supply to terminals A1 and A2 (Fig. 5).

Warning: Wiring only in de-energized state.

5. Starting the device:

Switch the operating voltage on.

Warning:

If the “Automatic start” starting behavior is set on the basic

device, the safety contacts will close immediately.

If the “Monitored manual start” starting behavior is set, close

the start button on the basic device to close the safety

contacts.

The LEDs K1 and K2 on the basic device and on the ESM-

ES3.. are lit.

6. Triggering safety function:

Open the emergency stop circuit by actuating the con-

nected safety switch. The safety contacts of the basic de-

vice and the ESM-ES3.. open immediately.

7. Reactivation:

Close the emergency stop circuit. If “Automatic start” is

selected on the basic device, the safety contacts will close

immediately.

If the “Monitored manual start” starting behavior is set, close

the start button on the basic device to close the safety

contacts of the basic device and the ESM-ES3...

Depending on the application, the device must be wired with a EUCHNER basic device as shown in Fig. 1 to Fig. 2. If the

devices are wired inside a control cabinet (minimum degree of protection IP54), the fault involving a short circuit between the

activation lines can be ruled out (protected wiring space). Category 4, PL e according to EN ISO 13849-1 is thereby possible.

If this fault cannot be ruled out, category 3, PL e is achieved.

Applications

Fig. 3: Feedback loop

Contactors connected to the ESM-ES3..

or the basic devices are monitored via

the feedback loop of the basic device. K

A

and K

B

are the positively driven contacts

of the connected contactor or expansion

module.

Fig. 2: Connection of several ESM-ES3.. units to

basic device

If further ESM-ES3.. units are to be integrated into the system,

terminals S11 must be connected in parallel on all ESM-ES3..

units. This also applies to terminals S10 and terminals S15/S16.

Fig. 1: Connection of ESM-ES3.. to basic device

Wiring of the ESM-ES3.. via only 4 lines:

A safety contact of the basic devices (e.g. 13-14) activates the

relays of the ESM-ES3.. (S11 and S15/S16).

Two lines on S23 and S24 are required for feedback/fault moni-

toring. A fault in the ESM-ES3.. thereby prevents the entire

safety chain from restarting.

Earth faults in the control lines are detected in addition to inter-

nal faults.

Wiring

Feedback Loop

Notice:

In order to activate earth fault monitoring, S10 must be con-

nected to PE (protective earth) on the AC115/230V devices.

With AC/DC 24 V, connect PE only to the power supply unit

according to EN60204-1.

Fig. 4: Feedback Loop with Auto-Start

Contactors connected to the ESM-ES3.. or the

basic devices are monitored via the feedback

loop of the basic device. K

A

and K

B

are the

positively driven contacts of the connected

contactor or expansion module.

Power supply

and

Safety contacts

Fig. 5:

Power supply A1 and A2.

(Power supply according to techn.

data )

Fig. 6:

Connecting load to safety contacts.

(Figure shows example.

Voltage „+V“ according to techn.

data)

S12