Emergency stop safety relay esm-ba3, User information – EUCHNER ESM-BA3xx User Manual

Page 3

3

User Information

EUCHNER GmbH + Co. KG Kohlhammerstraße 16 D-70771 Leinfelden-Echterdingen Tel. +49/711/75 97-0 Fax +49/711/75 33 16 www.euchner.de [email protected]

Emergency Stop Safety Relay ESM-BA3..

Maintenance

The device must be checked once per month for proper

function and for signs of tampering and bypassing of the

safety function.

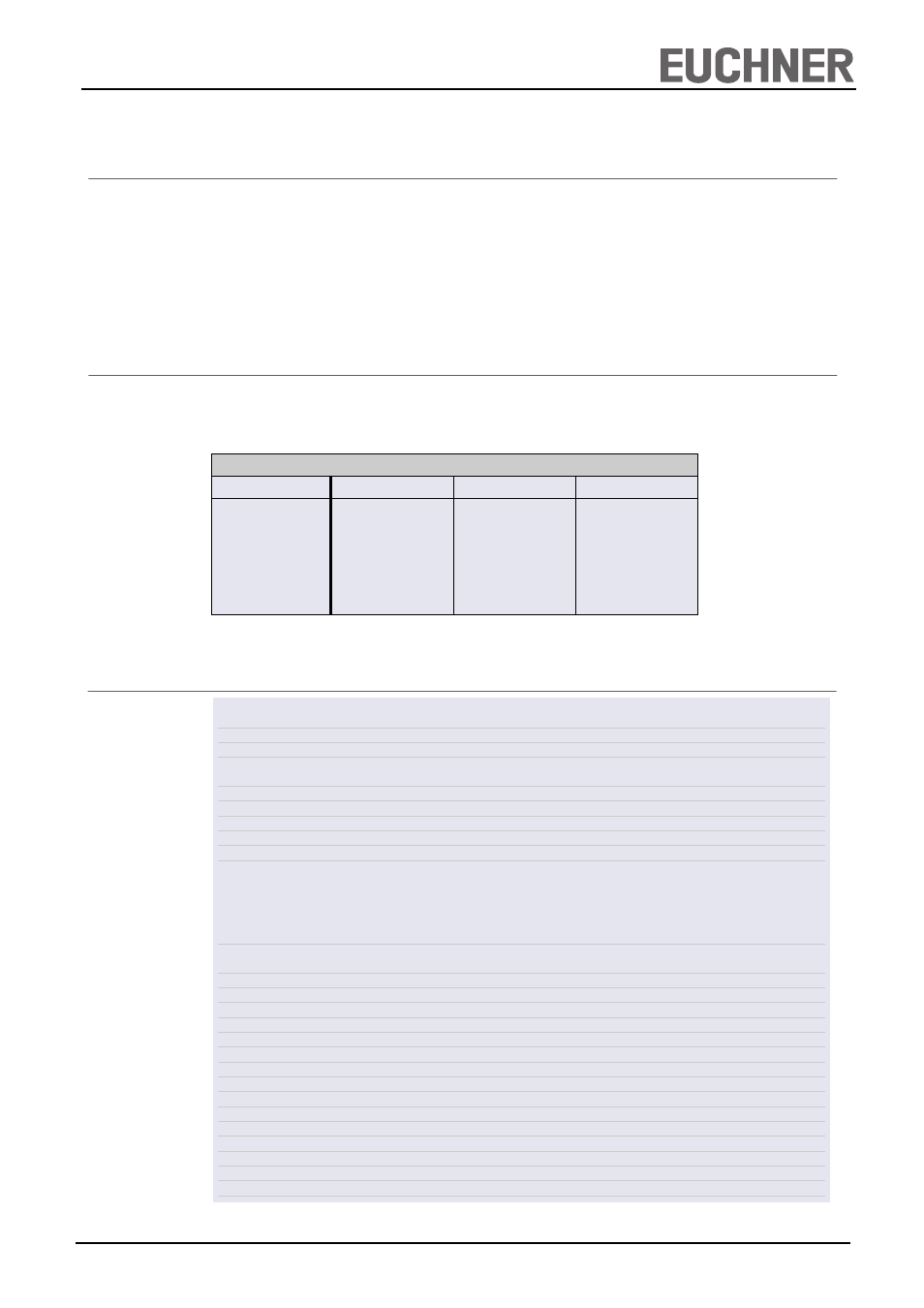

Techn. Data

Operating voltage

ESM-BA301 ESM-BA302 ESM-BA303

AC/DC 24V

AC 115V

AC 230V

Rated supply frequency

50-60 Hz

Permissible deviation

+ / - 10%

Power consumption

DC 24V

AC 230V

approx. 2.3 W approx. 6.9 VA

Control voltage at S11

DC 24 V

Control current S11...S14

approx. 60 mA

Safety contacts

3 NO contacts

Auxiliary contacts

1 NC contact

Max. switching voltage

AC 250 V

Safety contact breaking capacity (13-14, 23-24, 33-34)

AC:

250 V, 2000 VA, 8 A for ohmic load,

250 V, 3 A for AC-15

DC: 50 V, 400 W, 8 A for ohmic load;

24 V, 3 A for DC-13

Max. total current through all 3 contacts

15 A (13-14, 23-24, 33-34) *)

Auxiliary contact breaking capacity (41-42)

AC: 250 V, 500 VA, 2 A for AC-12

DC: 50 V, 100 W, 2 A for DC-12

Minimum contact load

24 V, 20 mA

Contact fuses

6 A slow-blow or 8 A quick-action or 10 A gG

Line cross section

0.14 - 2.5 mm

2

Max. length of control line

1000 m with 0.75 mm

2

Contact material

AgNi

Contact service life

mech. approx. 1 x 10

7

, electr. 1 x 10

5

operating cycles

Test voltage

2.5 kV (control voltage/contacts)

Rated impulse withstand voltage, leakage path/air gap

4 kV (DIN VDE 0110-1)

Rated insulation voltage

250 V

Degree of protection

IP20

Temperature range

-15°C to +40°C *)

Degree of contamination

2

(DIN VDE 0110-1)

Overvoltage category

3

(DIN VDE 0110-1)

Weight

approx. 230 g

Mounting

DIN rail according to EN 60715TH35

Safety

Characteristics

According to

EN ISO 13849-1

Note:

Additional data can be requested from the manufacturer for

applications that deviate from these conditions.

The device is certified according to EN ISO 13849-1 up to a

Performance Level of PL e.

Device cannot be switched on again after an emergency

stop:

•

Check whether the emergency stop circuit was closed

again.

•

Was the start button opened before closing of the emer-

gency stop circuit (with manual start)?

•

Is the feedback loop closed?

If the fault still exists, perform the steps listed under

“Commissioning Procedure”.

If these steps do not remedy the fault either, return the

device to the manufacturer for examination.

Opening the device is impermissible and will void the

warranty.

Device does not switch on:

•

Check the wiring by comparing it to the wiring diagrams.

•

Check the safety switch used for correct function and

adjustment.

•

Check whether the emergency stop circuit is closed.

•

Check whether the start button (with manual start) is

closed.

•

Check the operating voltage at A1 and A2.

•

Is the feedback loop closed?

What to Do in

Case of a Fault?

The device is otherwise maintenance free, provided that it

was installed properly.

*) If several ESM-BA3.. devices are closely spaced under load, the max. total current at the ambient temperature of T=20°C: 9A; at T=30°C: 3A; at T=40°C =1A.

If these currents are exceeded, a spacing of 5 mm between the devices must be observed.

Safety characteristics according to EN ISO 13849-1 for all variants of ESM-BA3

Load (DC-13; 24V)

<= 0,1A

<= 1A

<= 2A

T10d [years]

20

20

20

Category:

4

4

4

PL

e

e

e

PFHd [1/h]:

1,2E-08

1,2E-08

1,2E-08

nop [cycle / year]

<= 500.000

<= 350.000

<= 100.000