S-5-e clamp, Example profiles – Englert S5-E Mini User Manual

Page 2

Distributed by

S-5!

®

Warning! Please use this product responsibly!

Products are protected by multiple U.S. and foreign patents. Visit the website at www.S-5.com for

complete information on patents and trademarks. For maximum holding strength, setscrews should

be tensioned and re-tensioned as the seam material compresses. Clamp setscrew tension should be

verified using a calibrated torque wrench between 160 and 180 inch pounds when used on 22ga steel,

and between 130 and 150 inch pounds for all other metals and thinner gauges of steel. Consult the S-5!

website at www.S-5.com for published data regarding holding strength.

Copyright 2011, Metal Roof Innovations, Ltd. S-5! products are patented protected.

S-5! aggressively protects its patents, trademarks and copyrights.

The strength of the S-5-E clamp is in its simple design.

The patented setscrews will slightly dimple the metal

seam material but will not puncture it—leaving roof

warranties intact.

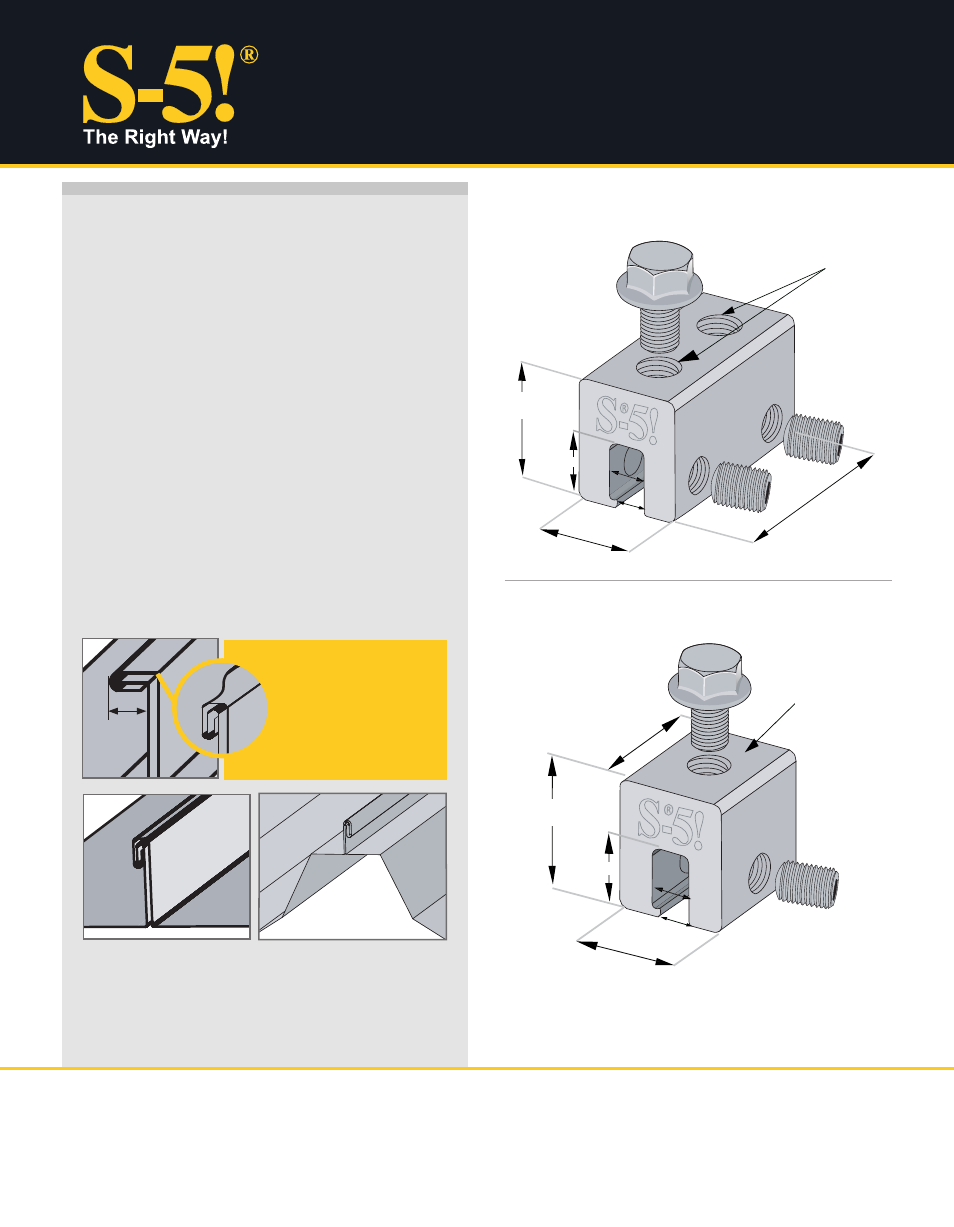

S-5-E Mini Clamp

S-5-E Clamp

Please note: All measurements are rounded to

the second decimal place.

The S-5-E and S-5-E Mini clamps are each furnished with

the hardware shown to the right. Each box also includes

a bit tip for tightening setscrews using an electric screw

gun. A structural aluminum attachment clamp, the S-5-E

is compatible with most common metal roofing materials

excluding copper. All included hardware is stainless

steel. Please visit www.S-5.com for more information

including CAD details, metallurgical compatibilities and

specifications.

The S-5-E and S-5-E Mini have been tested for load-to-

failure results on a variety of double-folded standing

seam roofs, from leading manufacturers of panels and

panel-forming machines. The independent lab test

reports found on our website at www.S-5.com prove that

S-5! holding strength is unmatched in the industry.

Hardware shown is included with each clamp.

Example Profiles

For horizontal seams under

.5" crimp the seam to 180

degrees at desired clamp

location.

This illustration demonstrates crimp-

ing technique, NOT actual location

of clamp.

≤ .5”

Hardware shown is included with each clamp.

1.18"

(30.00 mm)

0.98"

(25.00 mm)

1.97"

(50.00 mm)

0.60"

(15.00 mm)

M10 holes

located 13.00 mm (0.50")

from edges of part

1.18"

(30.00 mm)

0.98"

(25.00 mm)

1.18"

(30.00 mm)

0.30"

(7.60 mm)

M8 hole

centered on part

0.35"

(8.90 mm)

0.30"

(7.60 mm)

0.35"

(8.90 mm)

0.60"

(15.00 mm)