Ab+c – Enerpac P-392FP User Manual

Page 4

4

1. Cylinder does not advance,

advances slowly, or advances

in spurts.

1. Oil level in pump reservoir is

low.

2. Release valve open.

3. Loose hydraulic coupler.

4. Load is too heavy.

5. Air trapped in system.

6. Cylinder plunger binding.

1. Add oil according to the Maintenance

instructions on page 3 (paragrapgh 7.1).

2. Close the release valve.

3. Check that all couplers are fully tightened.

4. Do not attempt to lift more than rated tonnage.

5. Remove air according to the instructions on

page 3 (paragraph 6.0).

6. Check for damage to cylinder. Have cylinder

serviced by a qualified hydraulic technician.

1. Leaking connection.

2. Leaking seals.

3. Internal leakage in pump.

1. Check that all connections are tight and leak

free.

2. Locate leak(s) and have equipment serviced by

a qualified hydraulic technician.

3. Have pump serviced by a qualified hydraulic

technician.

3. Cylinder does not retract,

retracts part way, or retracts

more slowly than normal..

1. Release valve closed.

2. Pump reservoir is over-filled.

3. Loose hydraulic coupler.

4. Air trapped in system.

5. Hose internal diameter too

narrow.

6. Cylinder retraction spring

broken or other cylinder

damage.

1. Open release valve.

2. Drain oil level to full mark. See page 3

instructions for adding oil (paragrapg 7.1).

3. Check that all couplers are fully tightened.

4. Remove air according to the instructions on

page 3 (paragraph 6.0).

5. Use larger diameter hydraulic hose.

6. Have cylinder serviced by a qualified hydraulic

technician.

2. Cylinder advances, but does

not hold pressure.

Problem

Possible Cause

Solution

8.0 TROUBLE SHOOTING

7.4 Changing the Oil

1. Drain all oil and refill with clean Enerpac oil every 12

months. If pump is used in dirty environments, change the

oil more often.

2. Remove vent/fill cap or plug from reservoir.

3. Tilt pump to drain out old oil.

4. Fill reservoir only to level mark shown on pump.

5. Replace the vent/fill cap or plug.

6. Dispose of used oil properly.

8.0 TROUBLESHOOTING GUIDE

The following information is intended as an aid in determining

if a problem exists. For repair service, contact the Authorized

Enerpac Service Center in your area.

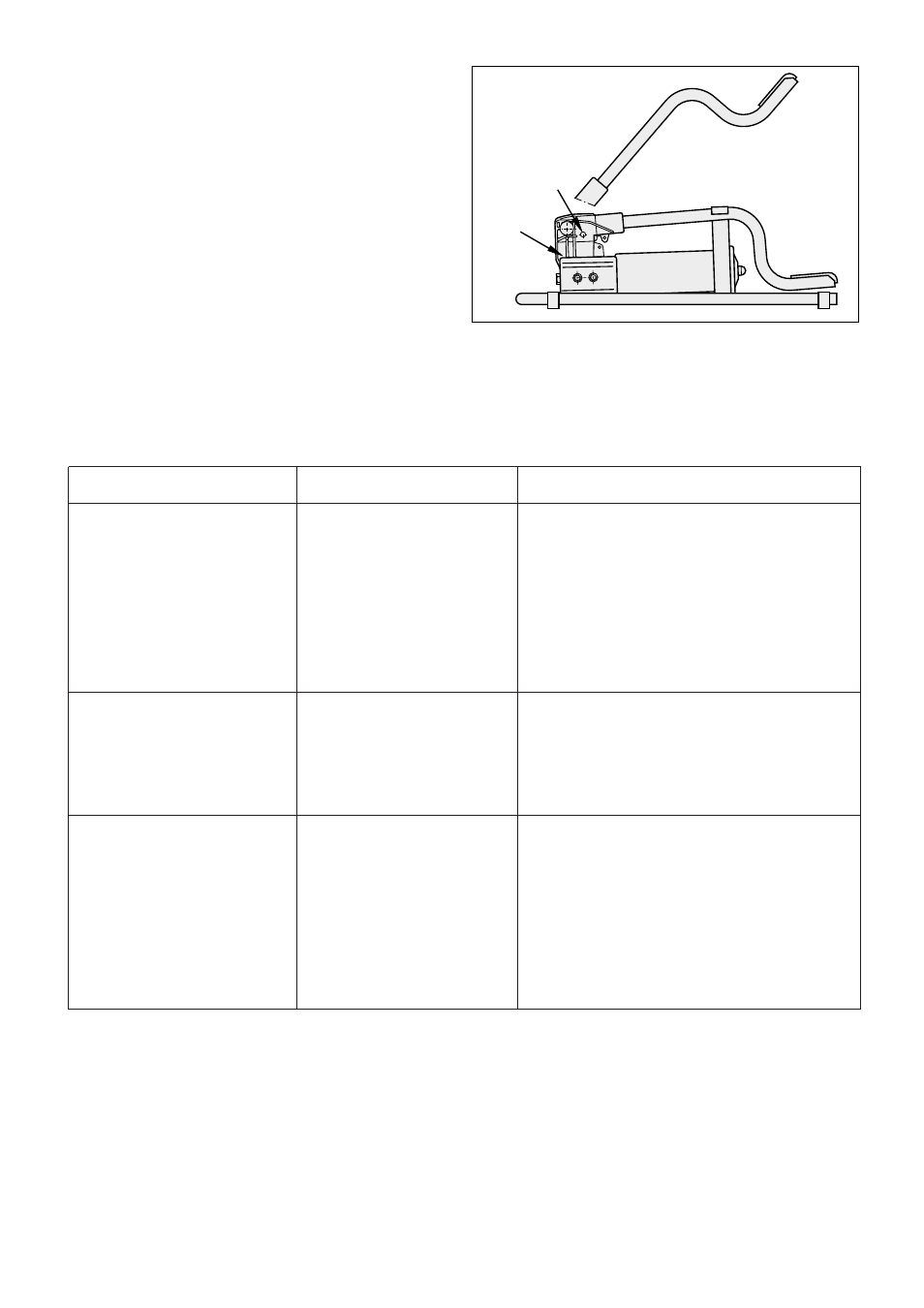

A

B+C

Figure 5