Enerpac PMU-Series User Manual

Page 5

5

CAUTION: DO NOT exceed maximum rated pressure

of torque wrench. See wrench nameplate for rating.

Watch pressure gauge.

CAUTION:

Check oil level after removing air.

Operating pump without a sufficient amount of oil

will damage pump.

NOTE: Perform “Air Removal” and “Relief Valve Adjustment:

1. during initial operation or start-up

2. when connecting a different wrench to the pump

3. when changing torque value (relief valve adjustment

only).

5.3 Pressure (Torque) Setting

WARNING: Make these adjustments BEFORE putting

torque wrench on nut or bolt head. The pump

pressure setting may be above the pressure needed

to provide the required torque for your application.

Exceeding required torque will cause equipment damage and

may lead to serious personal injury.

1. See torque wrench instructions for amount of pressure

required to produce desired torque.

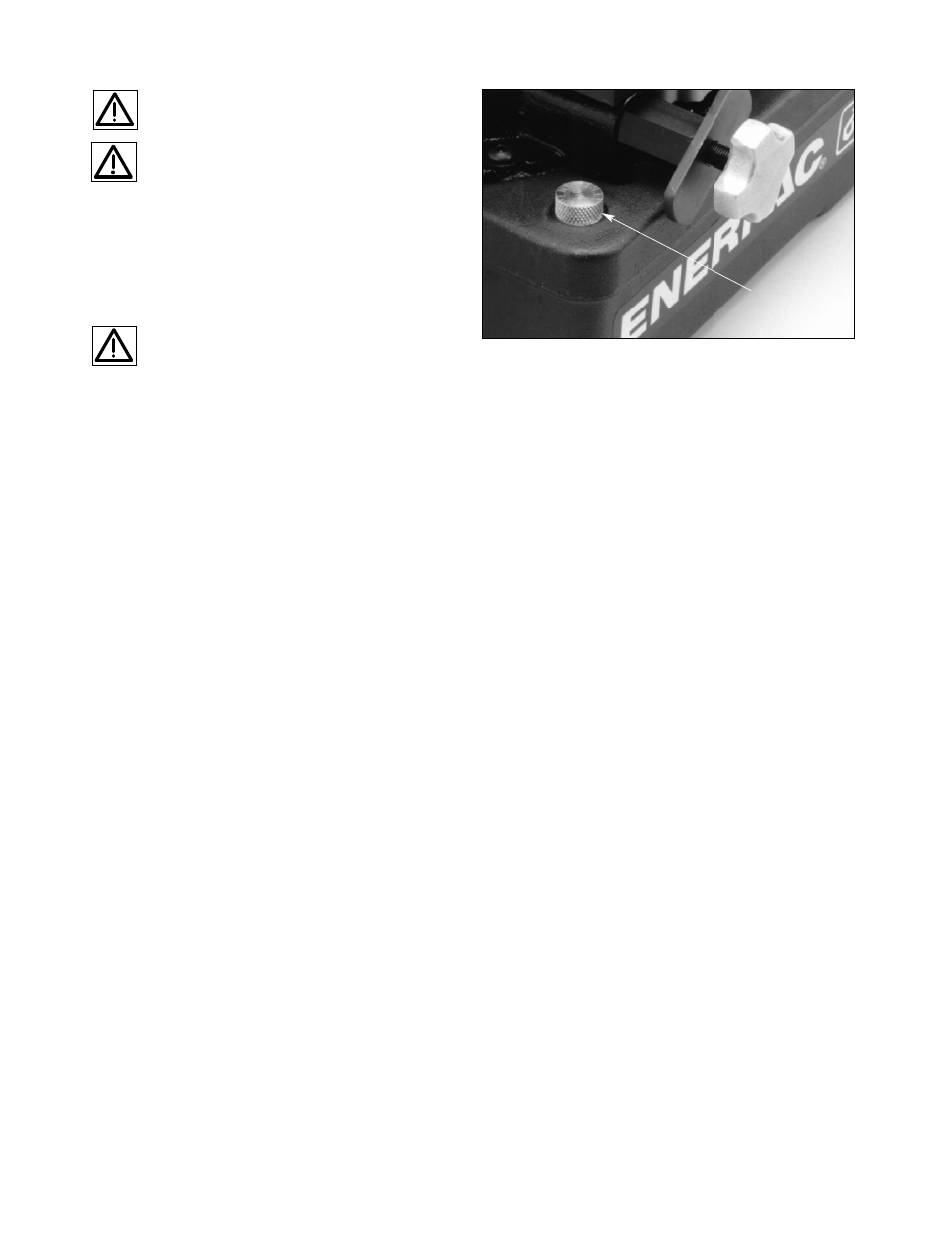

2. Loosen lock nut and back out relief valve to prevent

unintended pressure build-up. See Figure 1.

3. Turn pump on. Press and hold the “Advance”

pushbutton, and read pressure gauge.

4. While holding the push button, turn relief valve in

(clockwise) to increase pressure or out (counter-

clockwise) to decrease maximum pressure. Repeat

until correct pressure is obtained.

5. Tighten lock nut on relief valve to maintain setting.

6. Run pump several times to test this pressure setting.

NOTE: Refer to torque wrench instructions for wrench

operating procedure.

6.0 MAINTENANCE

6.1 Adding Oil to the Pump

Check reservoir hydraulic oil level every 40 hours of

operation. Add Enerpac hydraulic oil when necessary to

bring oil level up to 1 inch below the vent/fill opening.

6.2 Changing the Oil

Completely drain the reservoir after every 100 hours of

operation. If pump is operated in very dusty areas, drain

and refill after 50 hours of operation. If pump is operated

at high temperatures, oil must be changed more

frequently.

1. Remove the vent/fill plug from reservoir. (See Figure 6.)

2. Tip the pump until all old oil has drained out.

3. Add new Enerpac hydraulic oil through vent/fill opening

until the oil level is 1 inch below the vent/fill opening.

4. Replace the fill plug.

5. DISPOSE OF USED OIL PROPERLY.

6.3 Cleaning the Reservoir

The reservoir can be removed for cleaning. If the pump is

used in a dusty environment, the reservoir should be

cleaned once a year. Install a new gasket when you clean

the reservoir.

1. Remove vent/fill plug from reservoir.

2. Tip the pump until all old oil has drained out.

3. DISPOSE OF USED OIL PROPERLY.

4. You will need to remove the yellow shroud to get at the

screws that hold the pump to the reservoir. Use an Allen

wrench to remove the six screws securing shroud to the

reservoir.

5. Disconnect wire(s) from solenoid valve. Mark wires

before disconnecting from 4-way valve.

6. Lift shroud from reservoir. The electric motor is wrapped

in foam to help keep it cool and quiet. DO NOT remove

the foam insulation. Use care to avoid damaging wires

or pulling wire connections off terminals.

7. Remove eight screws holding pump to reservoir.

8. Lift pump from reservoir using care to avoid damaging

pick-up screens.

9. Remove gasket and discard.

10. Thoroughly clean the reservoir with solvent. Never use

water.

11. Use a soft bristle brush to clean intake screens. Rinse

with solvent.

12. Install a new gasket.

13. Secure pump to reservoir. Torque bolts to 36 - 42 in-lbs.

[4,1 - 4,7 Nm].

14. Place shroud over motor with shroud handle facing

valve side of pump.

15. Install the six mounting screws.

16. Reconnect wire(s) to solenoid valve.

17. Fill reservoir with new Enerpac hydraulic oil until oil

level is 1 inch below the vent/fill opening. Reservoir

capacity is 0.75 gallon (2.8 liters).

Figure 6, Vent/Fill Plug

Vent/Fill Plug