Enerpac PTA-Series User Manual

Page 4

4

NOTE:

Perform Air Removal and Pressure (Torque) Adjustment:

1.

during initial operation or start-up

2.

when connecting a different wrench to the pump

3.

when changing torque value (pressure adjustment only).

5.0 MAINTENANCE

5.1 Changing the Oil

Completely drain the reservoir after every 250 hours of operation.

If pump is operated in very dusty areas or at high temperatures,

drain and refill more frequently.

1.

Remove the breather cap from reservoir.

2.

Tip the pump until all old oil has drained out.

3.

Add new hydraulic oil through breather opening until the oil

level is one inch below the vent/fill opening. Reservoir capacity

is 1 gal. [3,7 L].

4.

Replace the breather cap.

5.

DISPOSE OF USED OIL PROPERLY.

5.2 Cleaning the Muffler

When the pump is run for long periods of time, ice may form on the

muffler element and must be removed.

To clean the muffler,

unscrew the front plate and remove any debris.

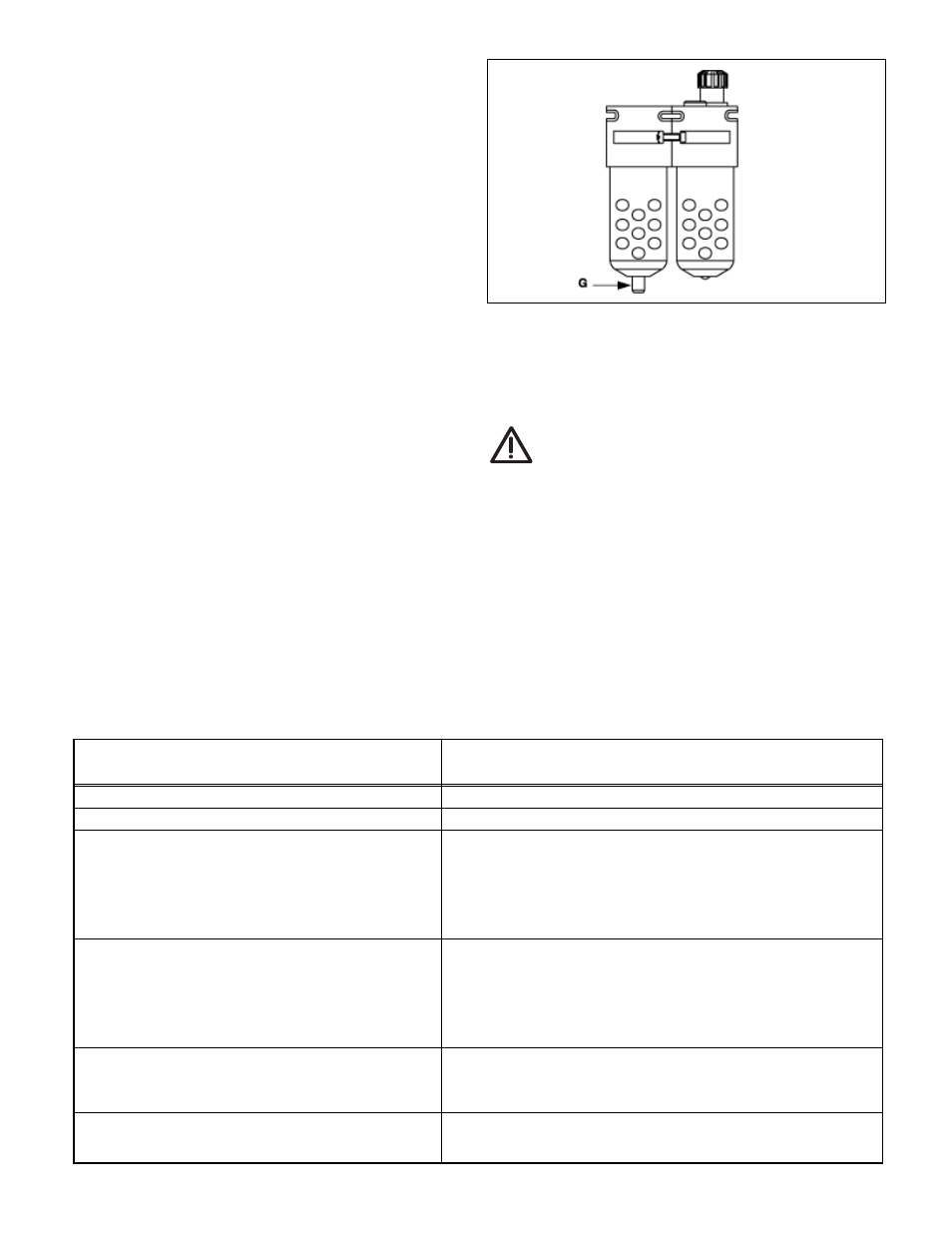

5.3 Cleaning the Air-Filter Lubricator

Inspect the air-filter lubricator frequently to detect crazing,

cracking, or damage. Replace damaged bowls.

Keep the filter bowl clean to maintain filtering efficiency. Turn drain

valve (G) clockwise from bottom to drain any bowl accumulation.

(See Figure 6.)

Figure 6

A visible coating of dirt or condensate on the filter element or an

excessive air pressure drop indicates that cleaning is necessary.

Depressurize the unit before removing bowl for cleaning.

CAUTION: Clean filter bowl with household soap

only.

6.0 TROUBLESHOOTING

Only qualified hydraulic technicians should service the pump or

system components. The following information is intended to be

used as an aid in determining if a problem exists. For repair service

contact your Enerpac Authorized Service Station.

Problem

Possible Cause

Pump will not start.

Air turned off or air line blocked.

Motor stalls under load.

Low air pressure.

Pump fails to build pressure.

External leak in system.

Internal leak in system.

Internal leak in valve.

Internal leak in system component.

Pump lost prime.

Pump builds less than full pressure.

Relief valve set low.

External system leak.

Internal leak in pump.

Internal leak in valve.

Internal leak in system component

Wrench will not retract.

Valve malfunction.

Return flow line restricted or blocked.

Low oil flow rate.

Inadequate air supply.

Dirty air filter.

Clogged inlet filter.