Enerpac ZUTP-Series User Manual

Page 5

5

5.5 Depressurizing the System

1. Slowly open the pressure release valve to relieve system

pressure. See Figure 4.

2. Verify that the pump pressure gauge indicates zero (0) psi/bar.

5.6 Circuit Breaker

CIRCUIT BREAKER

Press to Reset

Figure 8, Circuit Breaker

(See Figure 8)

The pump circuit breaker is

located on the pump front

panel, beside the pump jog

button.

In the event of an electrical

overload, the pump circuit

breaker will trip. After

investigating and correcting

the source of the overload,

push the circuit breaker

button to reset.

WARNING: To avoid injury and equipment damage, do

not continue pressurizing hydraulic tools after they

reach maximum travel or maximum operating pressure.

6.0 MAINTENANCE

Frequently inspect all system components for leaks or damage.

Repair or replace damaged components. Electrical components,

such as the power cord, may only be repaired or replaced by a

qualifi ed electrician, adhering to all applicable local and national

codes.

WARNING: Disconnect pump from electrical power

before performing any maintenance or repairs. Be sure

all hydraulic pressure is completely relieved (0 psi/bar).

6.1 Check Oil Level

Check the pump oil level prior to start-up. If oil level is low,

remove the oil fi ll plug from the cover plate and add oil as needed.

See fi gures 2 and 3. Always be sure that hydraulic tools are fully

retracted before adding oil to the reservoir.

6.2 Change Oil and Clean Reservoir

Enerpac HF oil is a crisp blue color. Frequently check oil condition

for contamination by comparing pump oil to new Enerpac oil. As

a general rule, completely drain and clean the reservoir every 250

hours, or more frequently if used in dirty environments.

Note: The following procedure requires that you remove the

pump from the reservoir. Work on a clean bench and dispose of

used oil in accordance with all applicable laws and regulations.

1. Disconnect pump from electrical power.

2. Remove the drain plug and drain all oil from the reservoir.

Clean and reinstall the drain plug.

3. Unscrew the 13 bolts holding the cover plate to the reservoir

and lift the pump unit out of the reservoir. Be careful not to

damage the oil intake fi lter screen.

4. Thoroughly clean the reservoir with a suitable cleaning agent.

5. Remove the oil intake fi lter screen for cleaning. (Do not pull

on the screen or the bottom of the intake to avoid possible

damage.) Clean the screen with solvent and a soft brush.

Reinstall.

6. Reassemble the pump and reservoir, installing a new reservoir

gasket.

7. Disassemble the hydraulic return line fi

lter. Clean and

reinstall (or replace) the fi lter element. Refer to Section 6.3 for

additional information.

8. Fill the reservoir with clean Enerpac HF hydraulic oil. The

reservoir is full when oil level is as shown in Figure 2.

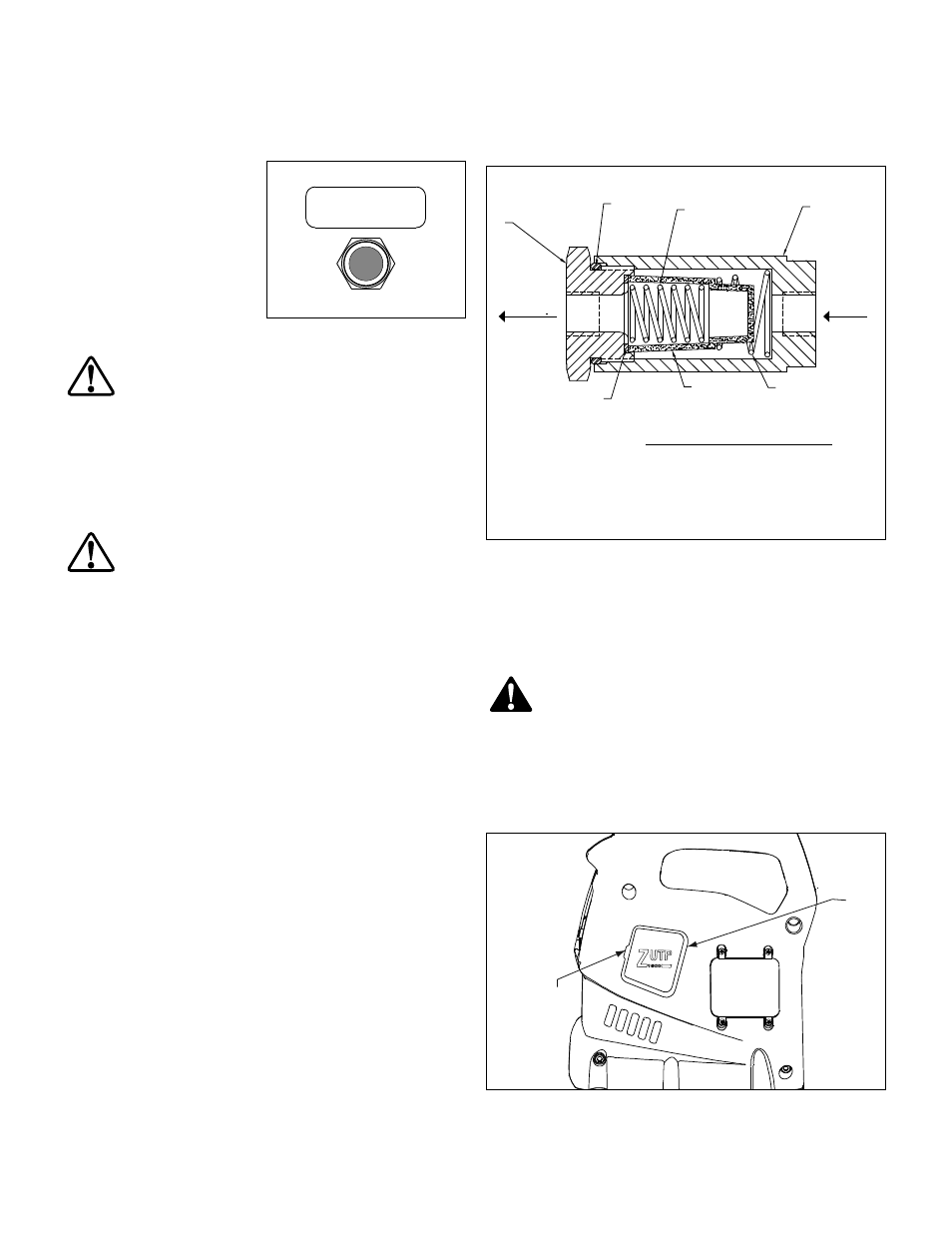

6.3 Hydraulic Return Line Filter (See Figure 9)

Remove and inspect the hydraulic return line fi lter element at

every oil change. The element can be cleaned and reused if it is

in good condition. However, a new element should be installed if

the old element is damaged or has been cleaned more than three

times.

OIL OUT

OIL IN

Note: For additional information,

go to

www.arrowpneumatics.com.

2

3

1

4

5

6

7

Key:

1. End Cap

2. O-Ring

3. Spring

4. Housing

5. Spring

6. Element, 90 Micron (Arrow P/N EK9052V-90)

7. Gasket

Figure 9, Hydraulic Return Line Filter

6.4 Motor Brush Replacement (See Figure 10)

To prevent motor damage, the pump motor brushes incorporate

an automatic motor stop when one of the brush carbons wears

to a length of 0.25" [6 mm]. Inspect both brushes.

1. Disconnect pump from electrical power.

DANGER: To avoid possible electrocution, pump must

be completely disconnected from electrical power

before brush servicing is attempted.

2. Remove both brush caps (A) by defl ecting the brush cap latch

(B) and gently prying outward. See Figure 10.

3. Remove motor brushes by turning black cap counter-

clockwise.

4. Replace both brushes and reverse procedure to reassemble.

A

B

Figure 10, Brush Cap Removal

A. Brush Cap

B. Brush Cap Latch