Open, Closed, Close open – Enerpac ZUTP-Series User Manual

Page 3

3

4.0 INSTALLATION

Install or position the pump to ensure that air fl ow around the

motor and pump is unobstructed. Keep the motor clean to

ensure maximum cooling during operation.

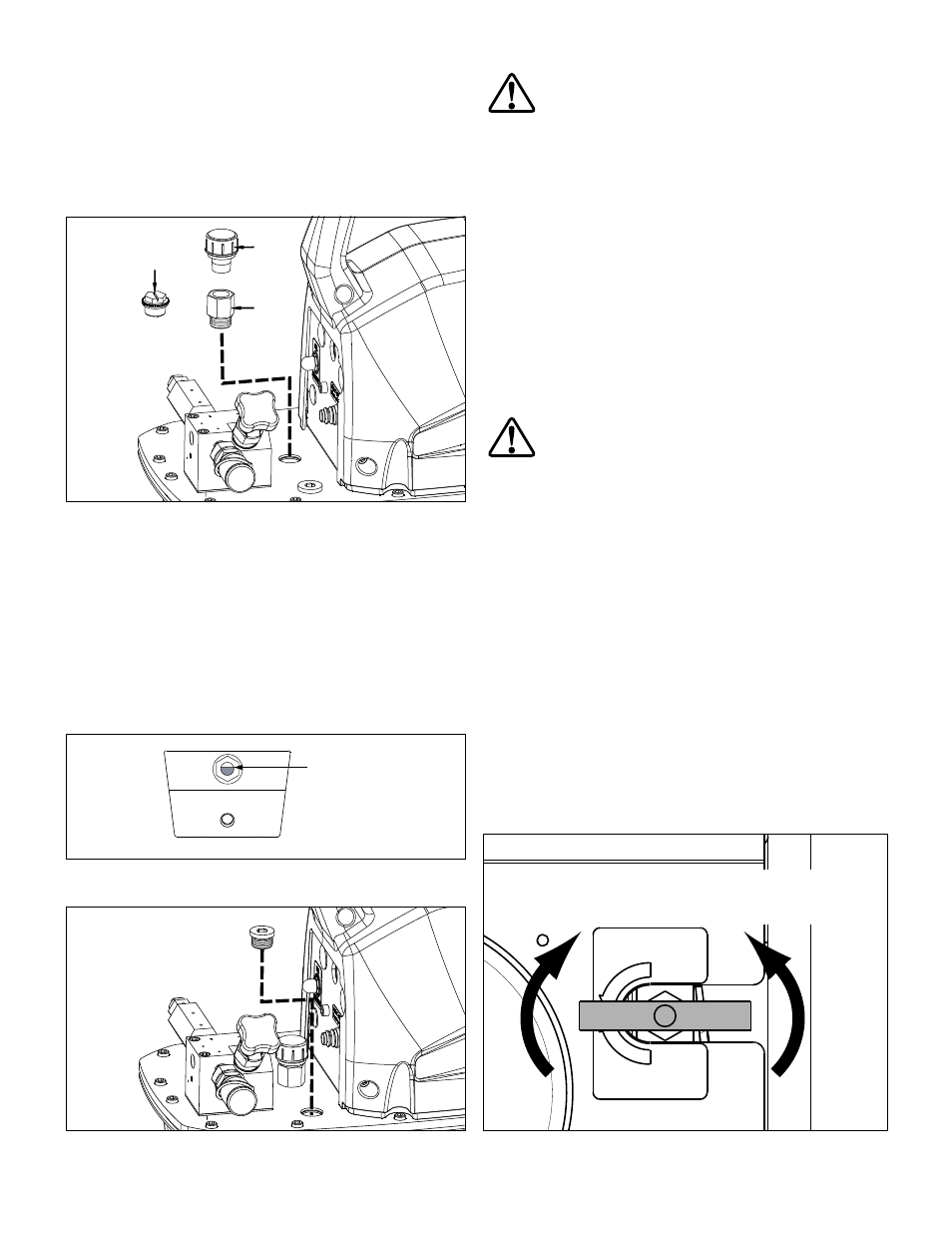

4.1 Air Breather (See Figure 1)

A shipping plug (A) is installed in the breather port on the top of

the reservoir. Before using the pump, replace the shipping plug

(A) with the air breather (B) and adapter fi tting (C).

A

C

B

Figure 1, Air Breather

4.2 Oil Level (See Figures 2 and 3)

Check the pump oil level prior to start-up. The reservoir is full

when the oil level is as shown in Figure 2. If necessary, remove

the oil fi ll plug from the cover plate as shown in Figure 3 and add

oil as required.

IMPORTANT: Add oil only when all system components are fully

retracted, or the system will contain more oil than the reservoir

can hold. Reservoir capacity is approximately 1 gallon [3,8 liters].

Tank is full

when oil level

is here.

Figure 2, Oil Level Sight Glass

Figure 3, Oil Fill Plug

4.3 Electrical Connections

WARNING: The pump is factory equipped with the

common electrical plug for a given voltage. Altering the

plug type should only be done by a qualifi ed electrician,

adhering to all applicable local and national codes.

• The disconnect and line circuit protection is to be provided by

customer. Line circuit protection is to be 115 percent of motor full

load current at maximum pressure of application.

• For additional information, refer to power rating on pump name

plate. Also refer to graph in Section 3.1.

4.4 Hydraulic Connections

• A female quick-disconnect fi tting (Enerpac Model BR150) is

installed at the pump oil outlet. This fi tting is rated at 21,750 psi

[1500 bar].

• Enerpac recommends the use of Enerpac HT 1500 Series

thermoplastic hoses with the Model ZUTP-1500 pump. These

hoses are rated at 21,750 psi [1500 bar]. Refer to Enerpac

instruction sheet L2733 for use, safety and maintenance

information.

WARNING: The Model ZUTP-1500 pump must be

operated only with hoses and fi ttings rated to operate

at 21,750 psi [1500 bar] working pressure. Hydraulic

hoses and fi ttings of a lower pressure rating will rupture or burst.

Serious personal injury could result!

• Before connecting hose to pump oil outlet, check that pump

pressure gauge indicates zero (0) psi/bar. If any pressure is

indicated, fully open the pressure release valve to relieve

pressure. See Section 5.1.

5.0 OPERATION

5.1 Pressure Release Valve (See Figure 4)

Valve Positions:

1. CLOSED - Flow directed to pump hydraulic outlet port.

Pressure builds when pump motor is turned on. Pump holds

pressure when motor is turned off.

2. OPEN - Pressure released to pump hydraulic reservoir.

Pressure will not build when motor is turned on.

IMPORTANT: Close the pressure release valve using hand force

only. Overtightening and/or use of tools may result in damage to

the valve and/or valve seat.

PRESSURE RELEASE VALVE

OPEN SLOWLY

DO NOT CLOSE

USING EXCESSIVE FORCE

CLOSE

OPEN

OPEN

(pressure release

to reservoir)

CLOSED

(oil fl ow to tool)

Figure 4, Pressure Release Valve