Motor jog – Enerpac ZUTP-Series User Manual

Page 4

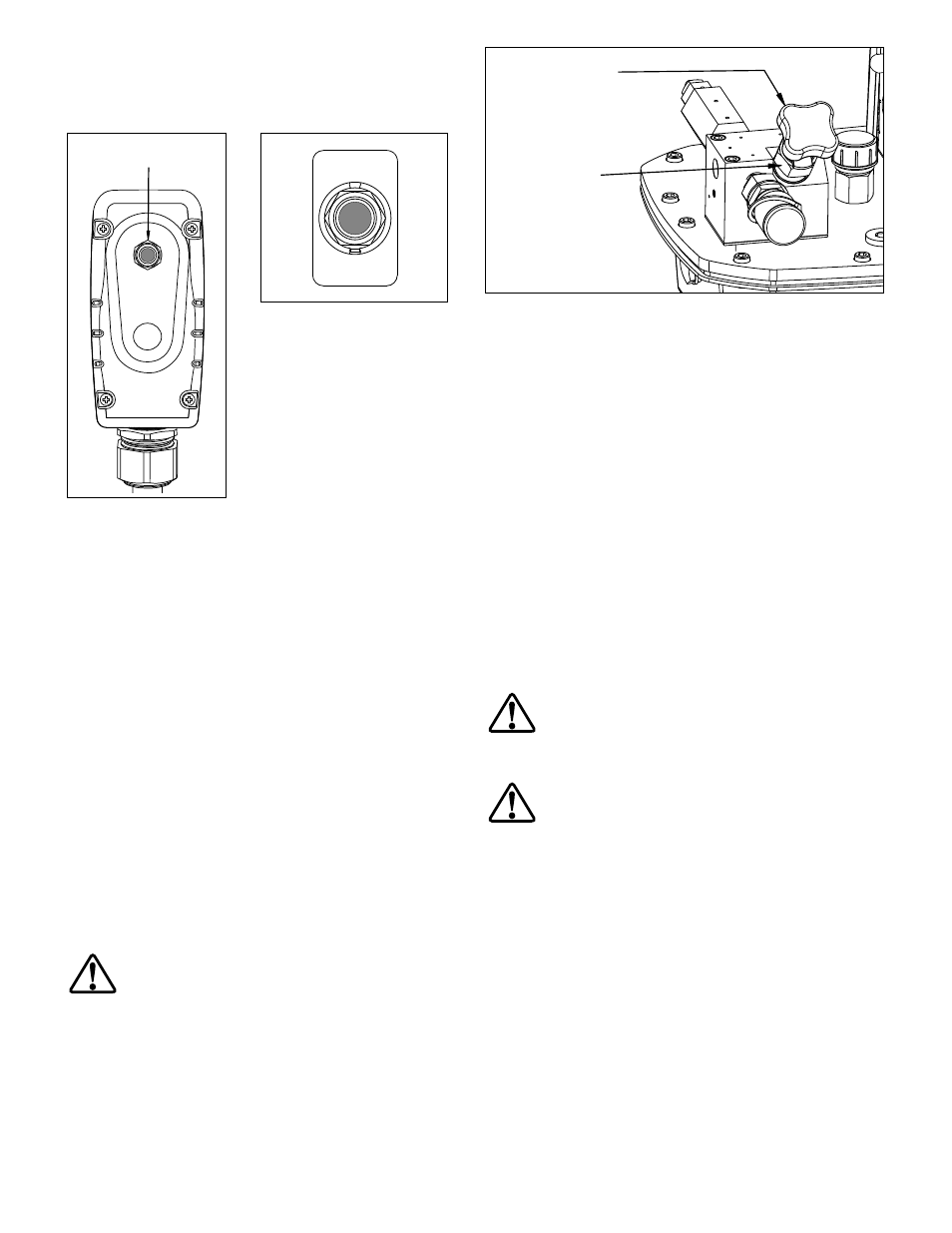

5.2 Pendant and Motor Jog Buttons

(See Figures 5 and 6)

The pump motor can be controlled either by the pendant button

or by the motor jog button (located on the pump front panel).

Operation is the same for both

buttons:

Button pressed:

Motor starts. System pressure

builds and tool is actuated for as

long as button is held down.

Button released:

Motor stops. Check valve holds

pressure until pressure release

valve is opened.

Note: Pressure release valve (see Figure 4) must be fully closed

to allow pressure to build while motor is running.

5.3 Adjusting the Relief Valve Setting (See Figure 7)

1. Remove hose (if connected) from the quick disconnect

coupler at the oil outlet port.

2. Fully close the pressure release valve. See Figure 4.

3. Loosen the relief valve locknut to allow pressure adjustment.

See Figure 7.

4. Turn the relief valve knob several turns counter-clockwise, so

that the relief valve is set lower than the desired setting.

Notes:

• When adjusting relief valve setting, always start at a low

pressure and slowly increase the pressure to the desired setting.

• If desired, the motor jog button can be used in place of the

pendant button during the following steps.

5. Check that pump is connected to electrical power.

6. Press and hold the pendant button. See Figure 5. The pump

motor will start and pressure will begin building immediately.

7. While continuing to press and hold the pendant button,

slowly turn the relief valve knob clockwise (as required) until

the desired pressure reading is shown on the pump pressure

gauge.

WARNING: Pump maximum working pressure is

21,750 psi [1500 bar]. Do not set the relief valve

pressure above 21,750 psi [1500 bar].

8. Release the pendant button. The pump motor will stop.

Locknut

Relief Valve

Knob

Figure 7, Relief Valve

Notes:

• Rotating the relief valve knob counter-clockwise will NOT

reduce or relieve existing system pressure.

• If pressure is adjusted too high, relieve pressure by opening the

pressure release valve (see Figure 4) until the pump pressure

gauge indicates zero (0) psi/bar. Then, fully close the pressure

release valve and repeat steps 6 through 8.

9. After verifying that setting is correct, tighten the relief valve

locknut (hand tight only - do not overtighten) to lock the

setting. See Figure 7.

10. Slowly open the pressure release valve to relieve pressure

in the oil outlet line. See Figure 4. Verify that pump pressure

gauge indicates zero (0) psi/bar.

5.4 Pressurizing the System

1. Adjust the relief valve setting. Refer to Section 5.3.

2. Connect hydraulic hose(s) and tool(s). Refer to Section 4.4.

3. Close the pressure release valve. See Figure 4.

4. Check that pump is connected to electrical power.

CAUTION: Before pressurizing the system, read and

understand all instructions and safety precautions

applicable to the hydraulic tool(s) being used. Follow

safe work practices in accordance with all applicable laws,

regulations and industry standards.

CAUTION: Continuously monitor the pump pressure

gauge while pump is running. Pressures can rise faster

than anticipated.

5. Press and hold the pendant button. See Figure 5. The pump

motor will start and pressure will begin building immediately.

6. When the desired reading is shown on the pump pressure

gauge, release the pendant button. The pump motor will

stop.

Note: Time required to pressurize the hydraulic circuit will vary,

depending on the number and type of tools connected, hydraulic

hose lengths and other factors.

Pendant Button

Figure 5, Pendant

MOTOR

JOG

Figure 6, Motor Jog Button

4