Elkhart Brass Universal Seal Replacement Kit For Elkhart Brass and Akron Brass Apparatus Valves User Manual

Page 2

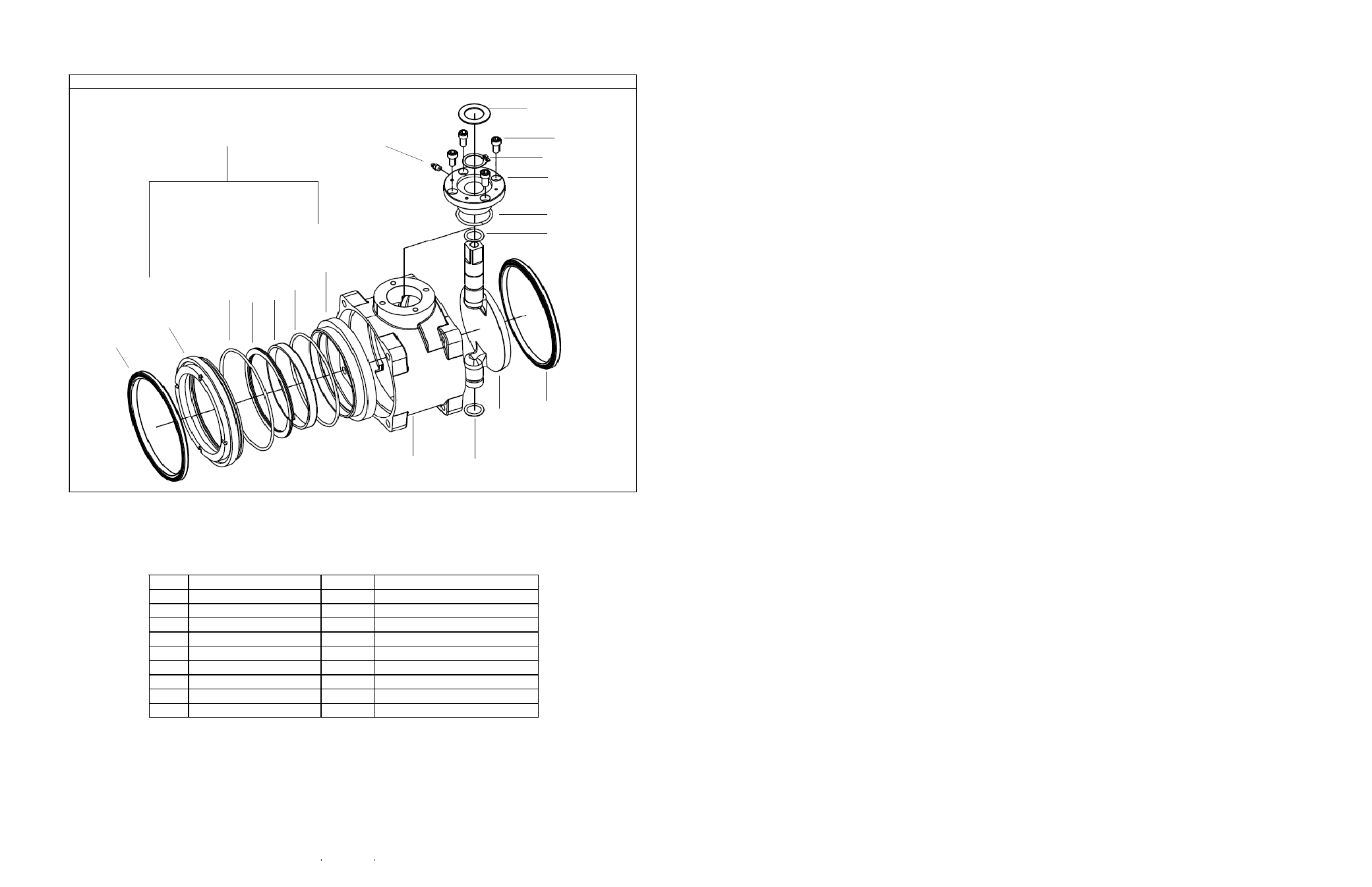

4” Valve Detail – Akron and Elkhart

2.

Inspect the condition of the flat ball for burrs, nicks and sharp edges caused by debris. If found, carefully use fine

emory paper to remove any condition which might cut the valve seat or otherwise impair sealing.

CAUTION: Completely remove any grit or debris from the valve body before assembly.

III.

REASSEMBLY

NOTE: Lubricate O-rings with Parker O-Ring Lube or equivalent petroleum-based lubricant.

1.

Install the new inner O-ring (6) and outer O-ring (3) on the retaining ring (2).

2.

Reinsert the seat spring (4) into the cavity of the retaining ring (2).

3.

Insert the seat support ring (5) into the new seat (7) with the chamfered edge to the inside of the seat.

4.

Insert seat into the seat retaining ring (2).

5.

Replace the entire assembly (18) into the valve body.

6.

Insert the two new adapter seals (1) into the valve body.

7.

Slide valve back into waterway.

NOTE: 4” valves are directional. Note the orientation of the arrow on the side of the valve body indicating flow

direction.

CAUTION: The ball must be in the open positon before the adapter bolts are tightened.

8.

Tighten the adapter bolts evenly in an X pattern using 60-70 ft-lbs torque. DO NOT OVERTIGHTEN.

MAINTENANCE INSTRUCTIONS

Do not lubricate the ball or seats. Lubricants can collect dirt and grit which may cause excessive wear.

Occasionally, flow water through all valves to clear dirt and debris.

OPERATING INSTRUCTIONS

Always open and close valves slowly.

I.

DISASSEMBLY

1.

Turn the valve to the closed position.

2.

If the valve can be rotated out of line, remove three pairs of adapter bolts and loosen the fourth pair. Swing the valve out of

the line. If the valve cannot be rotated out of line, remove all eight adapter bolts and take the valve out completely.

NOTE: 4” Valves are directional. Note the orientation of the arrow on the side of the valve body indicating flow direction.

3.

Remove and discard both adapter seals (1).

4.

Partially open the valve to allow access to the seat assembly (18).

5.

Pull the entire seat assembly (18) out from the valve body.

6.

Discard the seat (7), retaining ring inner O-ring(6) and retaining ring outer O-ring (3).

II.

INSPECTION AND CLEAN-UP

1.

Use a 10” or larger flat file to clean up the flat surface of the adapters and mating surfaces of the valve body. Remove

any paint, corrosion or raised lip around the bolt holes.

DISCLAIMER: Any reference herein to other manufacturers’ names and/or their trademarks is used only for comparison

purposes or to indicate compatibility and is not in any way intended to indicate an association or affiliation with or sponsorship or approval

by that manufacturer.

Do not exceed 500 psi.

ITEM

DESCRIPTION

ITEM

DESCRIPTION

1

Adapter Seal

10

Flat Ball

2

Retaining Ring

11

O-Ring

3

O-Ring

12

O-Ring

4

Seat Spring

13

Gear Case Adapter

5

Support Ring

14

Grease Fitting

6

O-Ring

15

Retaining Ring

7

Seat

16

1/4 - 20 x 5/8 SHCS (4)

8

Body

17

Actuator Washer

9

O-Ring

18

Seat Assembly

18

8

2

1

3

4

6

7

14

17

16

15

13

12

11

1

10

9

5