Elkhart Brass HF-500 Hydro-Foam Nozzle User Manual

Hydro-foam nozzle

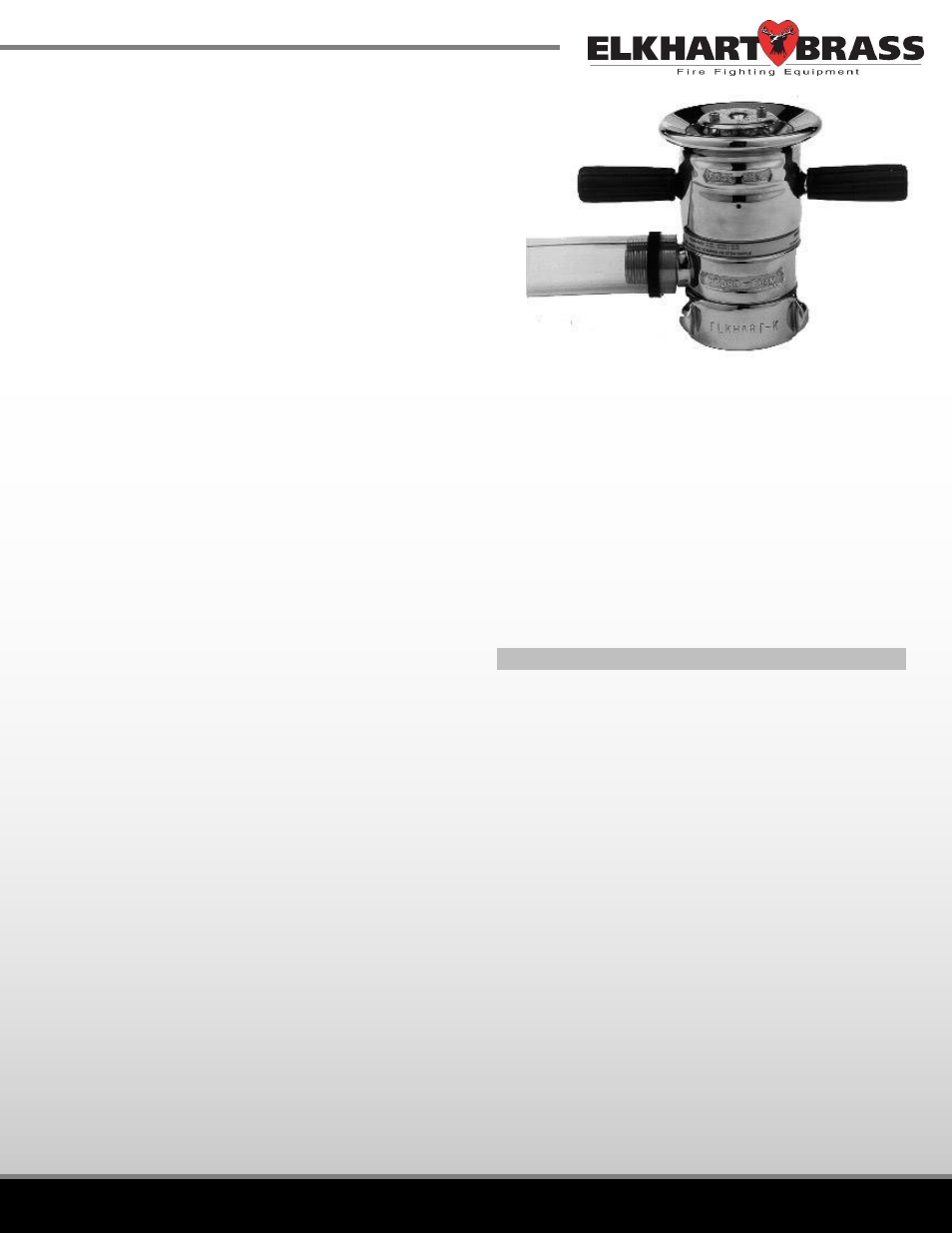

Hydro-Foam Nozzle

HF-350, HF-350-A, HF-500, & HF-500-A

Operating & Maintenance Instructions

The Hydro-Foam nozzle is one of the most

efficient and effective tools for AFFF firefighting

available today.

The nozzle’s unique design, with built-in

educator, allows it to be attached to any existing

fixed monitor, portable monitor, or deck gun.

The nozzle can also be used with plain water for

cooling exposures or for fire attack. When the

need arises for high application rates of AFFF,

simply inserting the pick-up hose into your foam

supply produces an instant AFFF foam system. In

many cases, knock-down of large fires can be

achieved while hand lines are being pulled for

final extinguishment.

The proportioning rate of these nozzles can be

changed easily in the shop or fire station.

Remove the foam inlet adapter or nipple, and

remove the previously installed foam metering

washer. Note: the HF-350 & 350-A, 6% setting

uses NO metering washer. The metering

washers will be marked 500 or 350 and the

percentage they are to be used for: ½%, 1%, or

3%. Insert new washer into the inlet nipple or

adapter, and thread it back into the nozzle body.

Loctite #262 should be used to secure

adapter/nipple threads.

The HF nozzles are factory set with a 3% metering

washer. A ½% & 1% washer is also provided.

The HF-350 is factory set for 3% proportioning,

for 6% use NO metering washer. Metering

washers for ½% and 1% proportioning are

provided. If you have chosen to use the optional

3-6% metering valve with your nozzle, DO NOT

INSTALL any of these washers.

Illustrations on the back of this sheet show

installation of the various available foam inlet

options. The quick connect coupling is a

convenience option. It allows you to keep the

suction hose stored until the need for foam

arises. You can then quickly attach the hose and

start foam operations. The quarter turn on/off

valve allows you to keep the suction hose

permanently attached to the foam supply and the

instant you need foam you can open the valve.

The 1-3% & 3-6% metering valves are ideal for

quickly switching between two types of foam. (1-

3% & 3-6% valves only available for HF-350 &

350-A)

MAINTENANCE INSTRUCTIONS

The HF-350 & 500 nozzles are constructed of

rugged brass alloys (HF-350-A & 500-A are

aluminum versions). The nozzle tip turns on a

cam mechanism to easily change stream

patterns. This cam should be lubricated

periodically with a light petroleum base grease

to insure smooth operation. If the tip becomes

hard to rotate (change patterns), by removing the

cam screw, you can slide the tip off the nozzle

body. Clean the inside of the tip as well as the

nozzle body and cam slot. Before reassembling,

apply a light coating of grease to the O-rings in

body and tip. Apply grease to cam slot. Clean

excess grease from nozzle after assembly to

prevent adhesion of dirt and grit to close

clearance parts.

As with any other foam appliances, be sure to

flush foam lines with clean water after each use.

1302

W

EST

B

EARDSLEY

A

VE

•

E

LKHART

,

IN

46514

•

574-295-8330

•

800-346-0250

98012000

R

EV

B

©

2013

E

LKHART

B

RASS

M

FG

.

C

O

.,

I

NC

.

•

WWW.ELKHARTBRASS.COM