Elkhart Brass 7095 EXM CAN Stow Module User Manual

Page 2

P

HYSICAL

:

1302

W

EST

B

EARDSLEY

A

VE

•

E

LKHART

,

IN

46514

•

WWW.ELKHARTBRASS.COM

©

2014

E

LKHART

B

RASS

M

FG

.

C

O

.,

I

NC

.

M

AILING

:

P.O.

B

OX

1127

•

E

LKHART

,

IN

46515

•

1-574-295-8330

•

1-800-346-0250

98533000

R

EV

REL

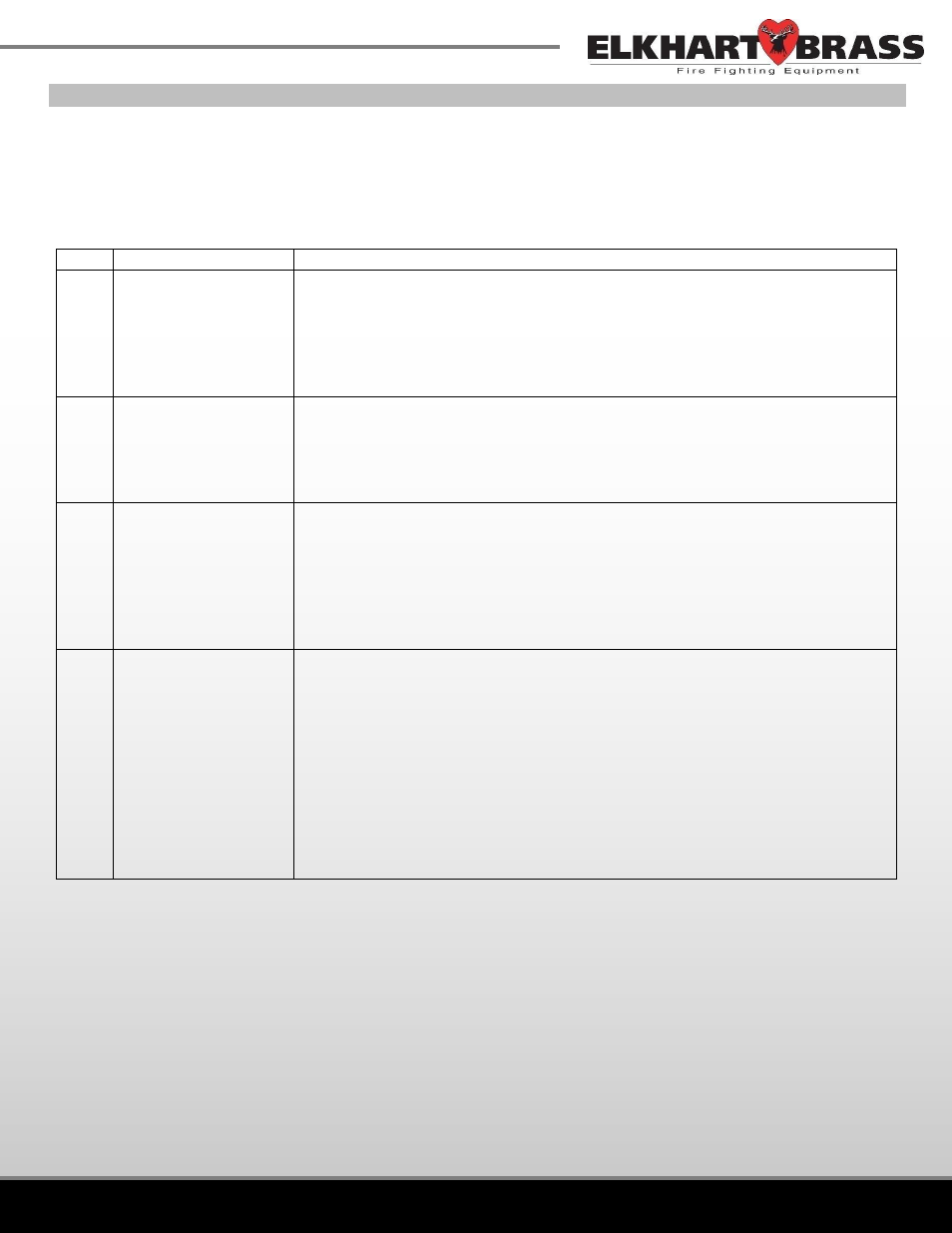

SYMPTOMS

STOWSIGNAL & STOWLAMP Outputs

If the 7095 Stow Module’s STOWSIGNAL or STOWLAMP outputs are not correctly operating after

following the instructions in an EXM monitor manual**, use Table 1 below to resolve the issue. The tips

are listed in the order for which they should be checked.

Table 1: Troubleshooting Tips

No.

Potential Cause

What to Check

1. The Stow Module,

7095, is not correctly

powered.

Verify that the 12-pin Deutsch connector is properly connected to the

7095.

Verify that the red and black leads (pins 12 & 1) are correctly connected to

the vehicle’s power supply and ground, respectively.

Inspect the cable for other damage.

Check fuses for the device power.

2. The Stow Module,

7095, is not

connected to the

J1939 CAN bus.

Verify that the 12-pin Deutsch connector is properly connected to the

7095.

Verify that the green and blue leads (pins 10 & 11) are correctly connected

to the CAN Low and CAN High bus through the 3-pin Deutsch connector.

Inspect the cable for other damage.

3. The STOWLAMP /

STOWSIGNAL is not

correctly connected to

the vehicle circuitry

Verify that the 12-pin Deutsch connector is properly connected to the

7095.

Verify that the brown, STOWLAMP (pin 4), and the white, STOWSIGNAL

(pin 5), lead(s) are correctly connected to the vehicle according to the

vehicle-specific application.

Inspect the cable for other damage.

Check any fuses connected to the STOWLAMP and STOWSIGNAL circuits.

4. The monitor’s stow

position is set too

close to a

vertical/horizontal

limit or a keep-out

zone.

Use an EXM input controller to put the monitor into Setup Mode (reference

Part B of the Operating Instructions section of the EXM monitor manual**.

Use the EXM input controller to set a stow position that is well away from

any vertical/horizontal limits or keep-out zones (reference the “Stow

Position” part of the Operating Instructions section of the EXM monitor’s

Installation, Operating, and Maintenance Manual).

Exit Setup Mode, then command the monitor to the new stow position.

If the Stow Module, 7095, now correctly operates, then this was the

problem. If desired, a different stow position can now be set on the

monitor using the previous steps: just be sure that it is not too close to any

horizontal/vertical limit or keep-out zone.

**EXM monitor manual refers to the Sidewinder EXM, Cobra EXM, Scorpion EXM, etc.