Caution – Elkhart Brass Cobra 7250 EXM Monitor User Manual

Page 5

5

SYSTEM COMPONENTS

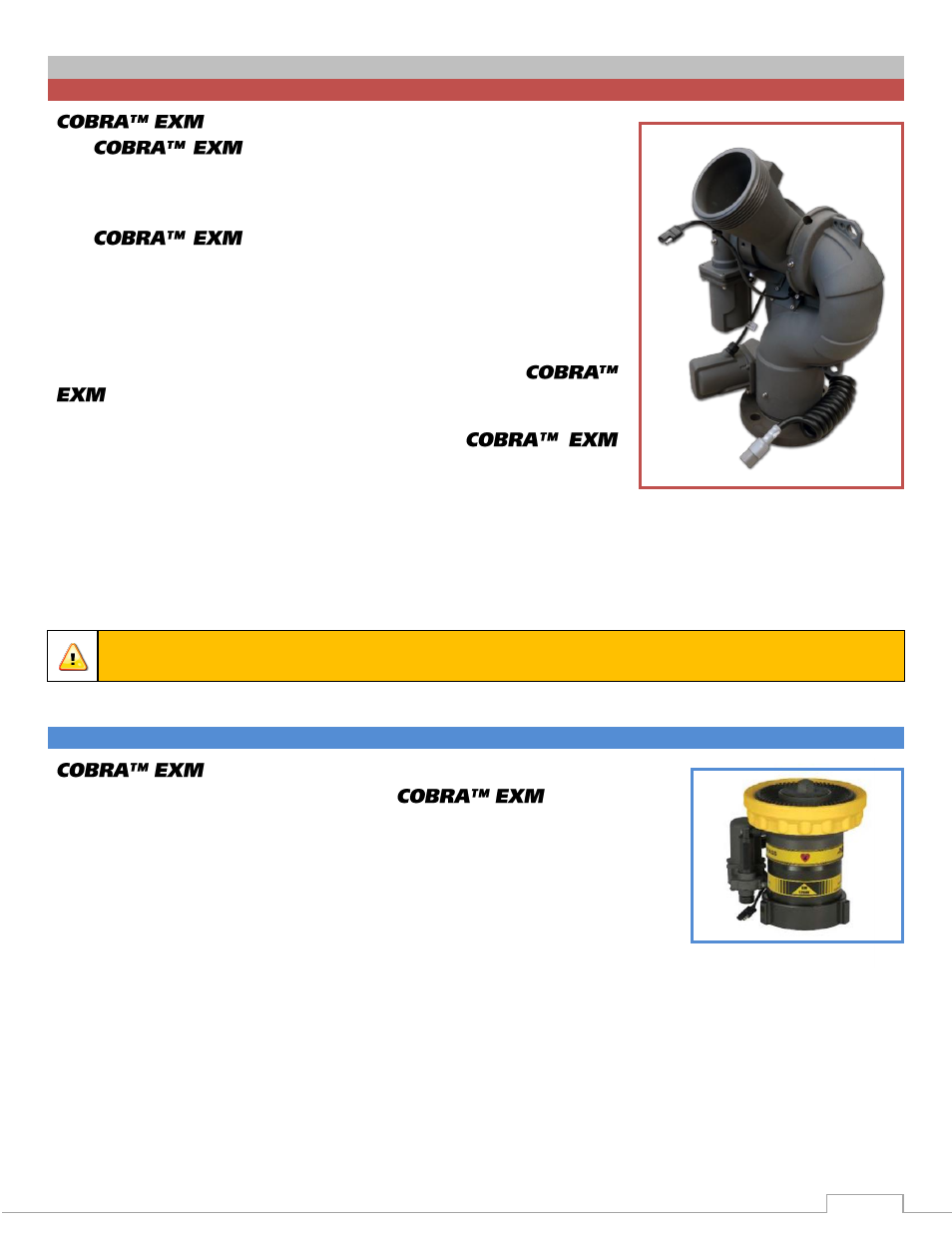

MONITOR

Monitor – 7250

The

monitor is specially designed to be compact

providing a greatly reduced swing radius. Unique waterway swivel

joints utilize stainless steel thrust rods, and needle roller thrust

bearings, for unprecedented durability in a range of applications.

The

utilizes a cast vanned waterway to minimize

large-scale turbulence. The monitor can be controlled by hardwired

input devices via CAN bus or by an optional upgraded Radio

Frequency (RF) device. The monitor may be powered with 12 or 24

volts.

Several base options are available for use with the

including a 3” flange, DN80-PN16 flange, 4” flange, 3”

female NPT, and 3” female BSPT. The discharge may be ordered

with either a 3.5” NHT or BSPP thread. The

comes standard with permanent magnet DC gear motors but may

be upgraded with high power, permanent magnet variable speed

DC gear motors. Both motor options are sealed to NEMA 4 for use

in harsh environments.

7250 SD – Standard Duty Motors

7250 HD – Heavy Duty Motors

Caution:

All EXM monitor motors are 12VDC. If using a non-EXM nozzle, another

12VDC nozzle should be used, or nozzle control may not function properly.

NOZZLE

Nozzles –

There is one nozzle rated perfectly for the

.

SM-1500E

The X-Stream series nozzles automatically adjust to maintain

effective stream and maximum reach at variable flows. These

nozzles have been calibrated to work at lower pressures, from

70 to 75 PSI, to better suit real world conditions.

SM-1500E; 500 GPM @ 50 PSI - 1500 GPM @ 70 PSI

1893 LPM @ 3.45 BAR – 5678 LPM @ 4.83 BAR

SM-1500E (P/N: 03781801)

Standard 7250 EXM Monitor

(00007205)