Final assembly, Wiring instructions, Double piggyback float switch installations – Clarus Environmental Turbine STEP Systems User Manual

Page 7: Fig. 12

7

Final Assembly

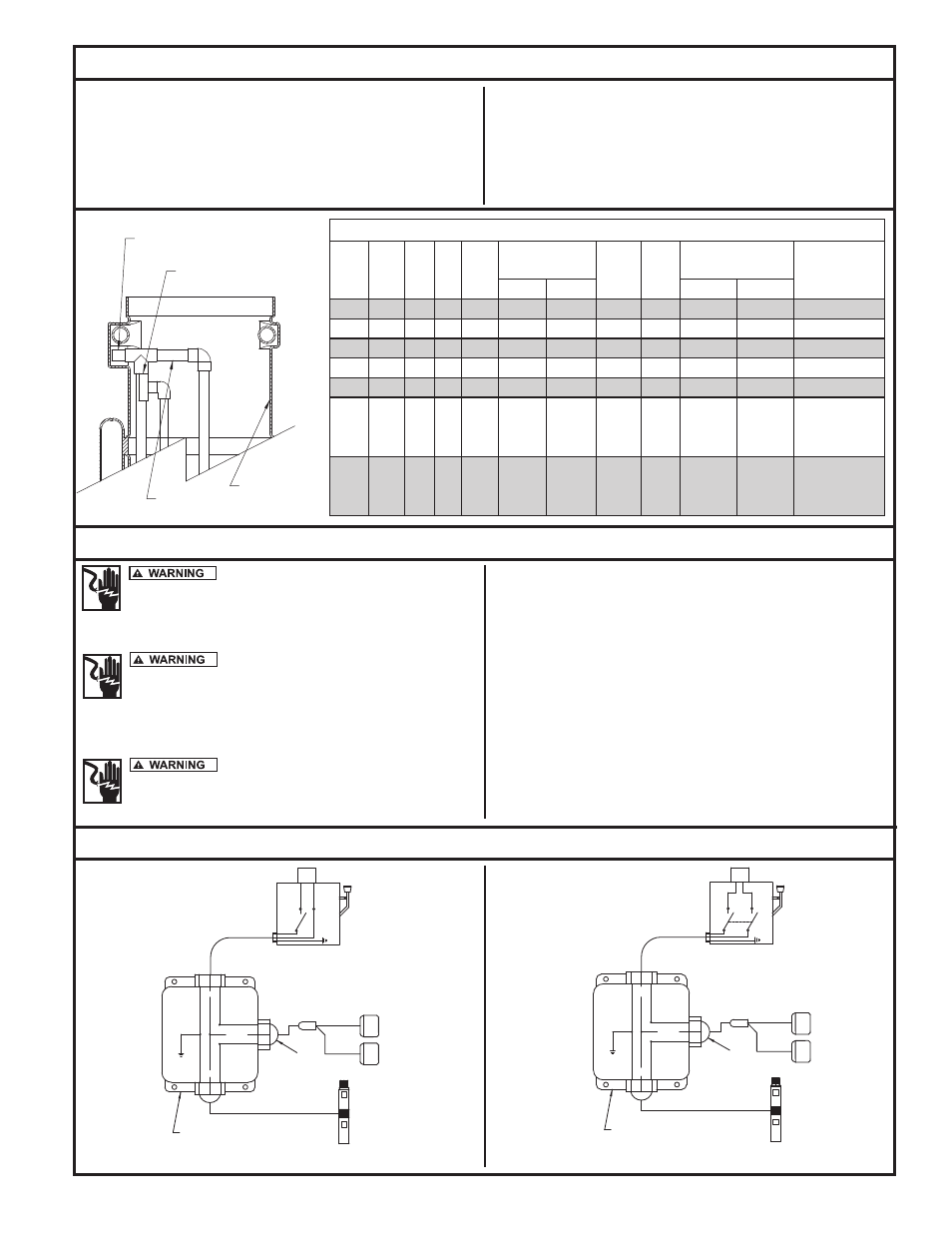

Electrical Data for Clarus Environmental Turbine Effluent Pumps

HP

Volts

Ph

Hz

S.F.

Maximum

Locked

Rotor

Amps

KVA

Code

Fuse/Circuit

Breaker Amps

Winding

Resistance

Line to Line

Amps

Watts

Std.

Delay

1/2

115

1

60

1.6

12

970

64.4

R

30

15

1.0 - 1.3

1/2

230

1

60

1.6

6

970

32.2

R

15

8

4.2 - 5.2

3/4

230

1

60

1.5

8

1325

40.7

N

20

10

3.0 - 3.6

1

230

1

60

1.4

9.8

1600

48.7

N

25

11

2.2 - 2.7

1 1/2

230

1

60

1.3

13.1

2250

56.8

L

35

15

1.5 - 1.9

2

230

1

60

1.25

Y 13.2

B 11.9

R 2.6

2650

51.0

G

30

15

1.6 - 2.3 M

5.2 - 7.15 S

3

230

1

60

1.15

Y 14.0

B 14.5

R 4.5

3650

82.0

G

45

20

.9 - 1.5 M

3.0 - 4.9 S

FILTER HOLDER

FILTER TANK

ATTACH FLOAT TREE RIGHT BELOW

THE FILTER HOLDER FITTING

TILT FILTER HOLDER TO LOCATE

IN ANTI-FLOTATION POCKET

SK2416

Fig. 12

Wiring Instructions

16. Place the filter holder assembly down in the pump vault, tilting it

toward the pump well side to allow the handle to be placed into the

anti-flotation pocket (see Fig. 1 & 13).

17. Place the float tree assembly down into the pump vault. The bottom

of the float tree must go into the top of the filter holder. Snap the

top of the float tree to the filter holder handle (see Fig. 1 & 12).

18. Connect the pump, floats, alarms and control panels. Follow in-

stallation instructions and wiring diagrams supplied with each.

19. After wiring, fill the septic tank with water. This must be done to

check the pump, float operating levels and the alarm. Be sure the

floats do not hang up during operation! Do not fully empty

the septic tank of water to help prevent float-out.

"Risk of electrical shock" Do not remove

the power supply cord and strain relief or connect conduit di-

rectly to the pump. Installation and checking of electrical cir-

cuits and hardware should be performed by a qualified and licensed

electrician.

For your protection, make certain that the

pump ground wire is properly connected to the ground

wire in the incoming power line. Test for ground at the junc-

tion box using an Underwriters Laboratory listed circuit ana-

lyzer which will indicate if the power, neutral and ground wires are cor-

rectly connected.

In 230 VAC pump installations, one side of

the line going to the pump is always hot. This condition exists

if the switch is on or off. Install a double pole disconnect on all

230 VAC pump circuits.

GENERAL WIRING RECOMMENDATIONS

• Follow the correct wiring diagram for your system.

• Use an auxiliary alarm with the double piggyback float switch op-

tion or any other control method that does not include a high water

alarm. Install the alarm inside the house or in a weather protected

location per installation instructions with the alarm kit. Make sure

the alarm is plugged into a different circuit than the pump circuit.

• If a junction box is being used, follow the installation instructions

and wiring directions with the junction box or follow the directions

below. All wiring, from the power source to the pump, must conform

to the National Electrical Code.

• Be sure to leave a sufficient amount of cord so the filter can be

serviced without disconnecting the cordage from the junction box

(see maintenance section).

LIQUID-TIGHT

CONNECTOR

G

N

L1

115V

PUMP

G

G

L1

G

115V

POWER

SOURCE

BLACK

RED

WHITE

N

115V

SWITCH

L1

N

JUNCTION BOX

RED

LIQUID-TIGHT

CONNECTOR

G

L2

L1

230V

PUMP

230V

POWER

SOURCE

L1

G

G

BLACK

WHITE

L2

L1

230V

SWITCH

G

L2

JUNCTION BOX

120 VAC

230 VAC

Double Piggyback Float Switch Installations

SK1837A

SK1837B

© Copyright 2011. All rights reserved.